Metal plated and polished ceramic products and their manufacture

A technology of ceramic products and production process, applied in the field of ceramic products, can solve the problems of rigidity, lack of three-dimensional sense and dull vision of ceramic products, and achieve the effect of strong three-dimensional sense, transparency and luster, and rich three-dimensional sense.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] like Image 6 Shown, the present invention carries out production according to following processing steps successively:

[0022] (1) carry out surface treatment to adobe 1;

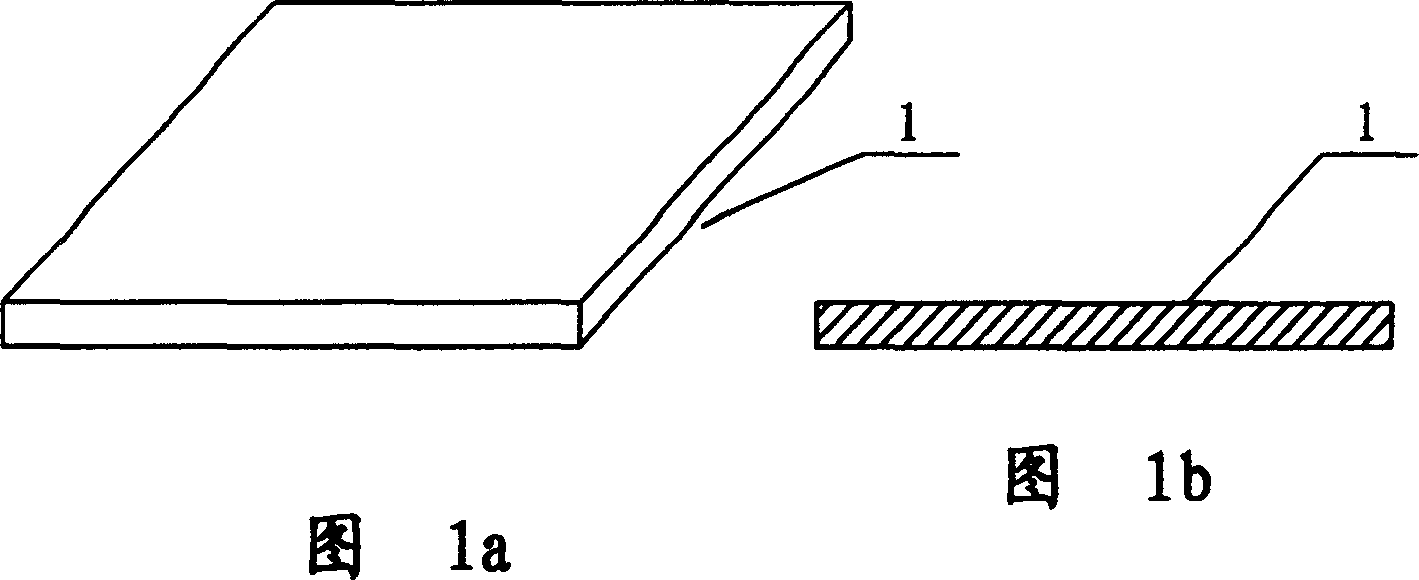

[0023] Shown in Fig. 1a, 1b is processed brick adobe 1, with cotton cloth, distilled water, the dirt on its ceramic upper surface is removed, then wipe dry.

[0024] (2) Print patterns on the upper surface of the adobe;

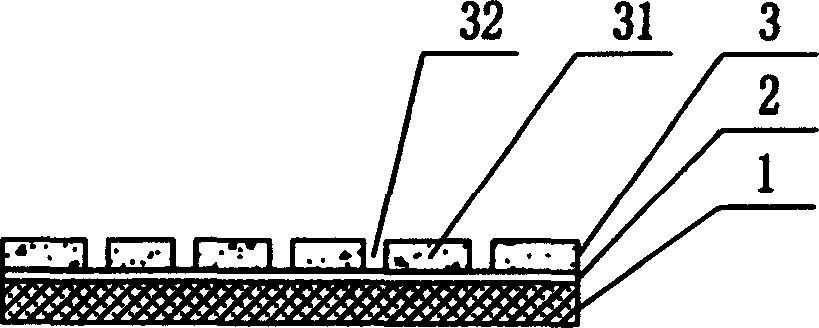

[0025] As shown in Figures 2a and 2b, the pattern layer 2 can be printed on the surface of the adobe 1, and pattern printing can be carried out by using a pattern screen making and printing machine, and the mesh number of the printing screen is 200-250 mesh. Patterns can also be made using other techniques such as drawing, glaze stacking or decals. The pattern 21 can be made into colorful patterns, especially natural stone or gem pattern. In this embodiment, the pattern 21 is divided into a plurality of irregularly shaped polygons by the contour lines 22 .

[0026] (3) spread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com