Composition, extraction process and use of total triterpene sapogenin extracted from bamboo

A technology for total saponins and sapogenins is applied in the field of composition of triterpenoid total sapogenins, which can solve the problems of long process flow, high content of heavy metals and pesticide residues, poor operating environment and the like, and achieves the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0070] Put Zhuru powder (generally controlled at 10-20 mesh particle size) into CO 2 In a supercritical extraction kettle, at a temperature of 50-65 °C, a pressure of 25-35 MPa, and with or without entraining agent, cyclic dynamic extraction is carried out for 2-5 hours to obtain the extract of Bamboo Ruba (EZR 2002 ). The entraining agent used can be organic solvents such as methanol, ethanol and acetone, and the dosage is generally CO 2 5-15% of the amount (v / v).

[0071] The following preferred examples describe the present invention in detail, but are not intended to limit the present invention.

example 1

[0072] Example 1 Put 5.5kg of Phyllostachys nigra var.henonis (Phyllostachys nigra var.henonis, also known as Phyllostachys nigra var. 2 The pump is boosted to 30 MPa, and enters the extraction kettle through the preheater; the entrainer pump is turned on, so that 10% volume ratio of acetone passes through the preheater and enters the extraction kettle at the same time, and the dynamic extraction is carried out at 55 ° C for 3 hours. Separation kettle 1 sets separation pressure to 8 MPa and temperature to 45°C, separation kettle 2 sets separation pressure to 5-6 MPa and temperature to 27-30°C; take out the target product from separation kettle 1 and dry at low temperature , after pulverization, the extract of Zhuru (EZR 2002 ) 121 grams, the productive rate is about 2.2%;

example 2

[0073] Example 2 In addition to using bamboo (Phyllostachys pubescens, also known as bamboo) as raw material, the extraction temperature is 60 ° C, the pressure is 25 MPa, and the time is 5 hours, except that the entrainer is changed to 10% ethanol by volume, the rest Same conditions as Example 1, EZR 2002 The yield is about 1.8%.

[0074] The present invention also provides supercritical CO 2 The Zhuru extract (code-named as EZR) obtained by extraction means 2002 ) product characteristics.

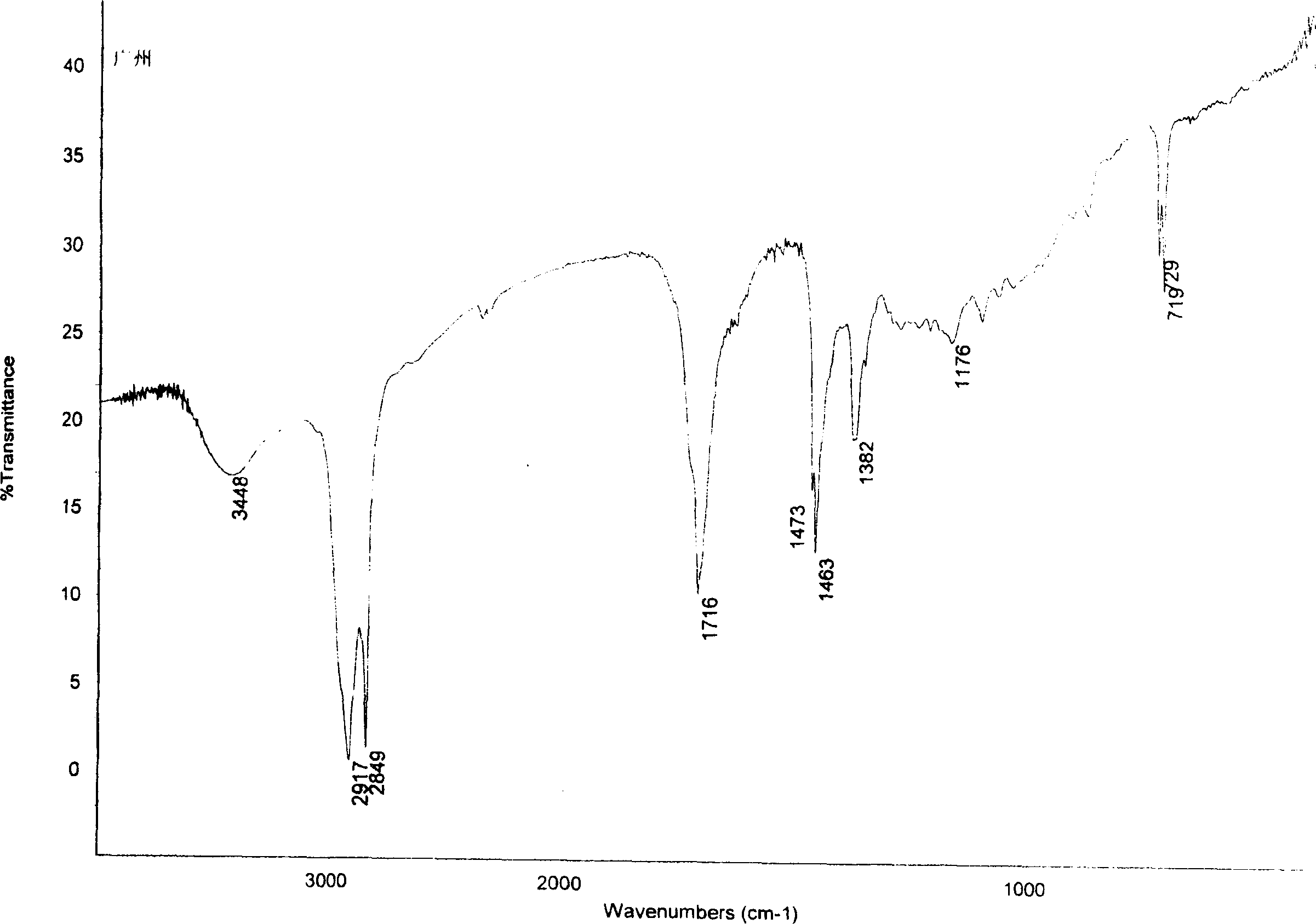

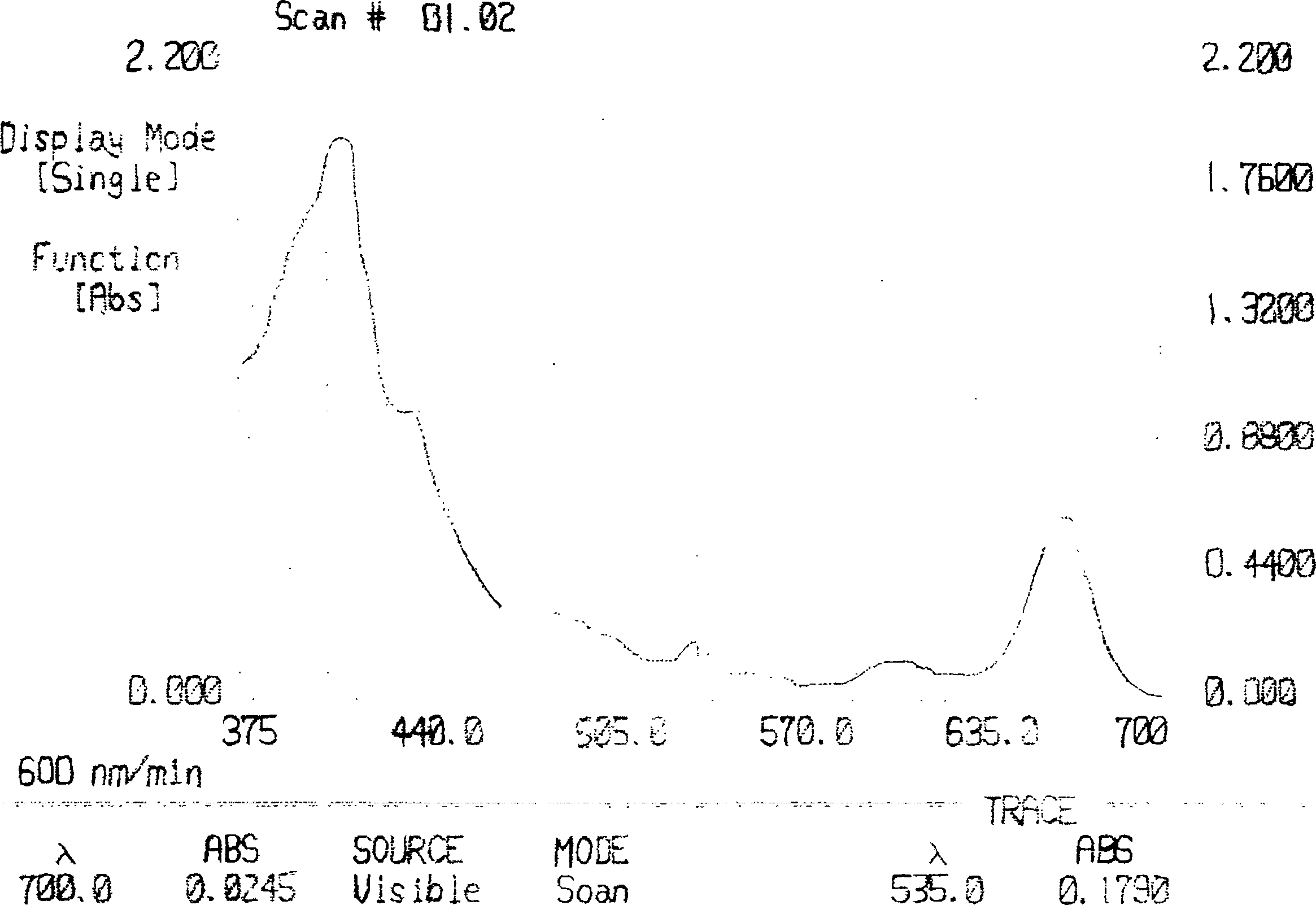

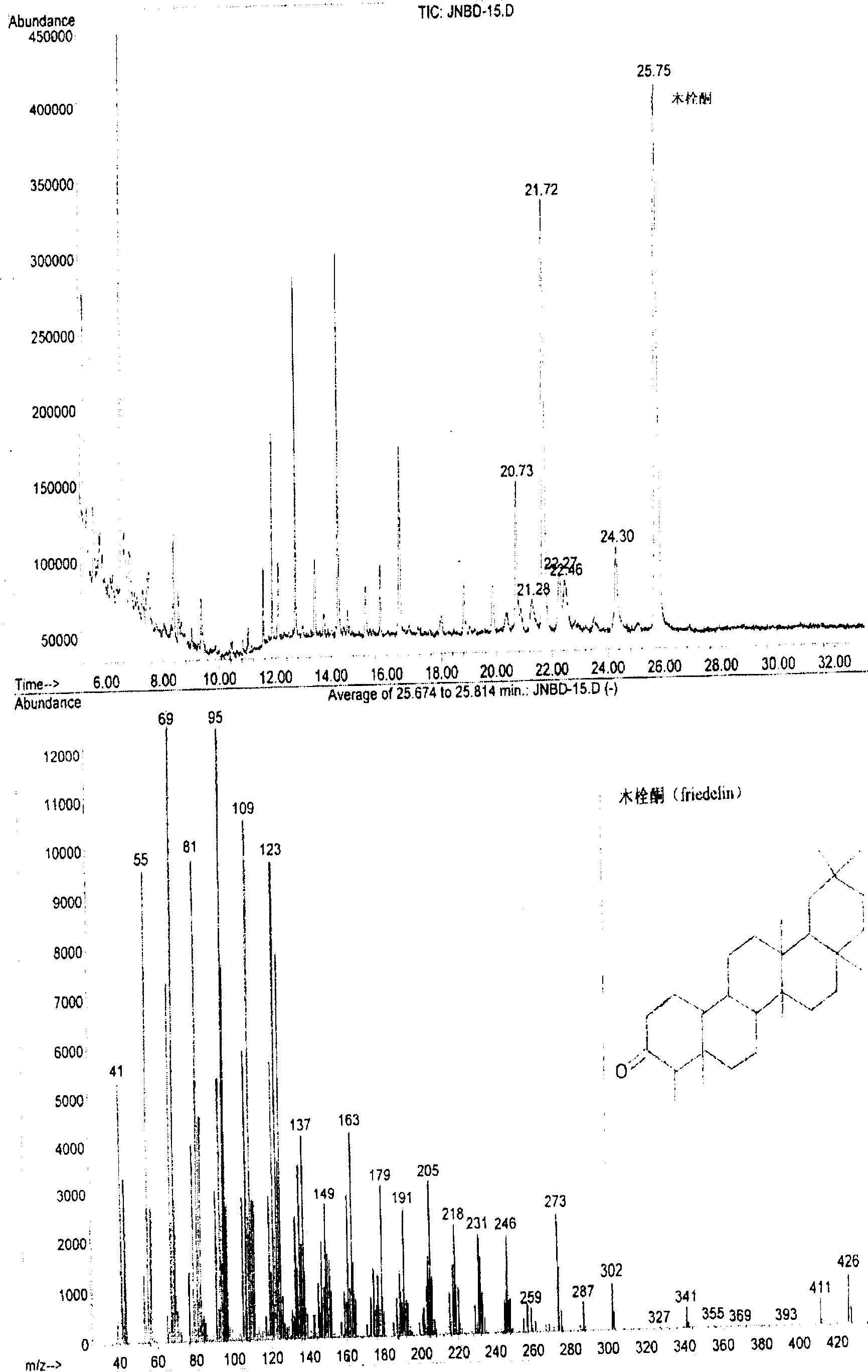

[0075] EZR 2002 It is a mixture of pentacyclic triterpenoids mainly composed of suberone, lupenone and their homologues. The appearance is yellow or yellow-green powder, and the melting point is between 74 and 79°C. The infrared spectrogram after potassium bromide compression shows that the mixture has -1There are characteristic absorption peaks (see attached figure 1 ). will EZR 2002 After dissolving in spectroscopically pure dichloromethane, scanning in the wavelength range of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com