Clutch assembly

A clutch and assembly technology, applied in the direction of clutches, friction clutches, fluid-driven clutches, etc., can solve the problems of expensive, complex structure of clutch assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

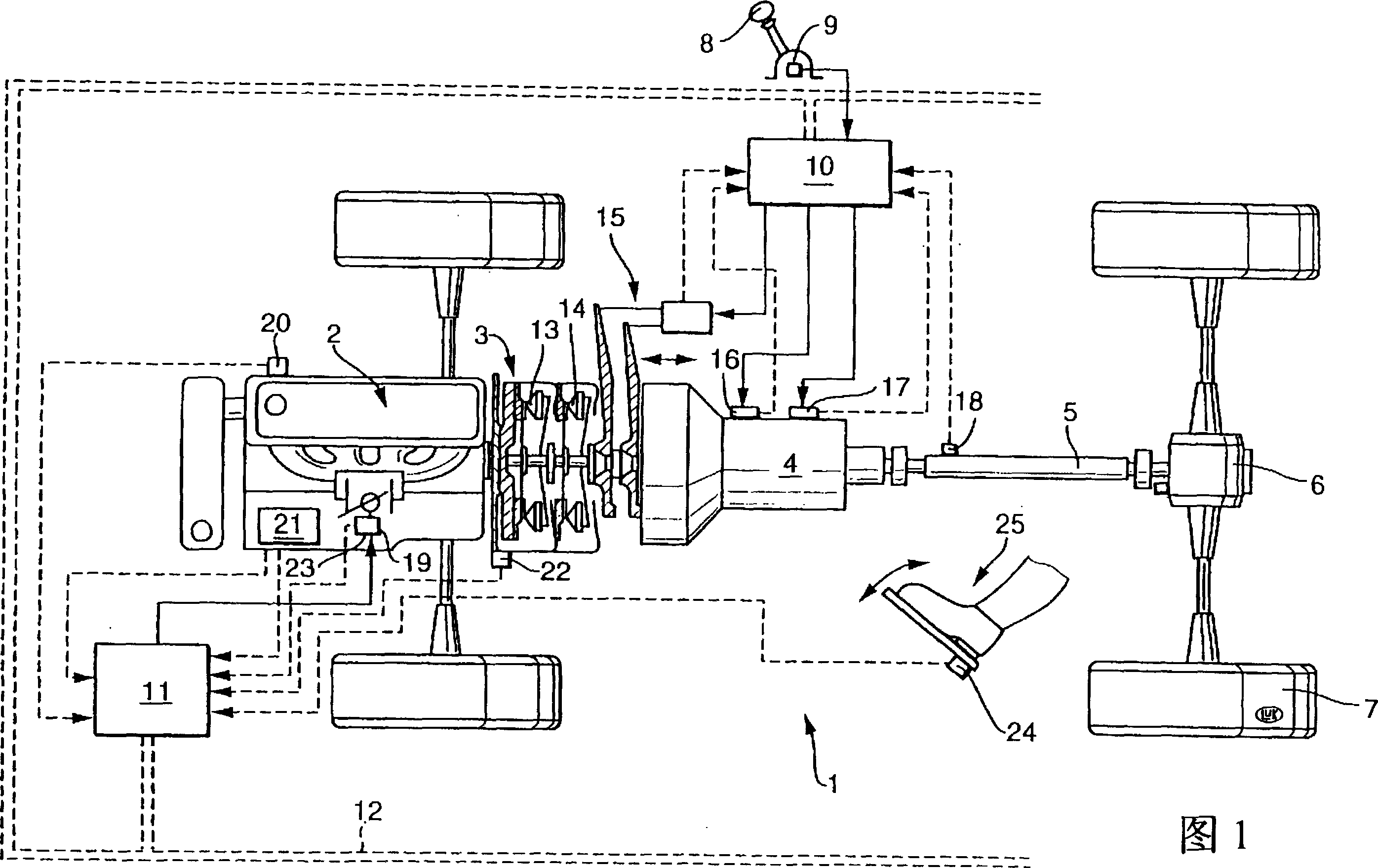

[0023] FIG. 1 shows a motor vehicle 1 with a transmission line comprising an engine 2 consisting of an internal combustion engine, a clutch assembly 3 and a gearbox 4 . Wheels 7 of motor vehicle 1 are driven via a drive shaft 5 and a differential 6 . In this sense, it can of course also be a motor vehicle with one or more other driven axles.

[0024] Also shown here is a gear selection device 8 , such as a selector lever, with a sensor 9 and a control device 10 , 11 in the form of a block diagram. The control devices 10 , 11 can be designed as one unit or in structurally and / or functionally separate subregions. If the control devices 10 , 11 are designed in structurally and / or functionally separate subregions, they can be connected to one another, for example, via a CAN bus 12 or other electrical connections for data exchange. The control devices 10, 11 are used, for example, to automatically operate the gearbox 4 and / or to control the clutches 13, 14 or the engine 2 to whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com