Capacitance type micromechanical switch

A capacitive micro-mechanical and micro-electronic mechanical technology, which is applied in the direction of circuits, electrical components, waveguide devices, etc., can solve the problems of affecting the switch threshold voltage, large residual stress, and reducing the service life of the switch, so as to achieve long switch life and low Threshold, Buck Threshold Voltage Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

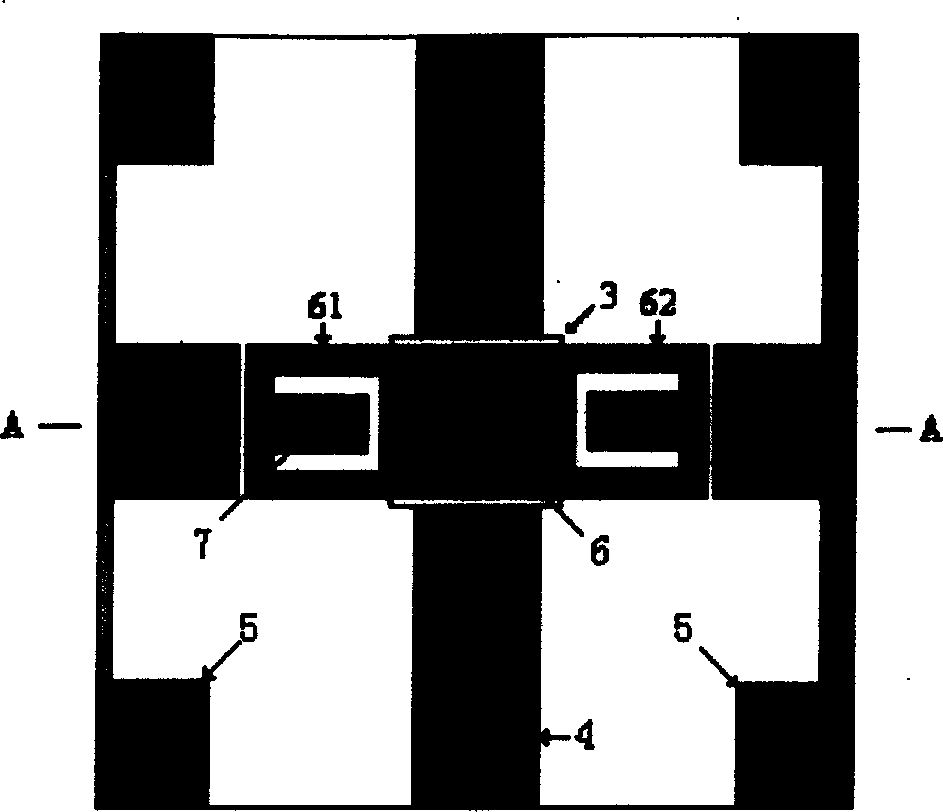

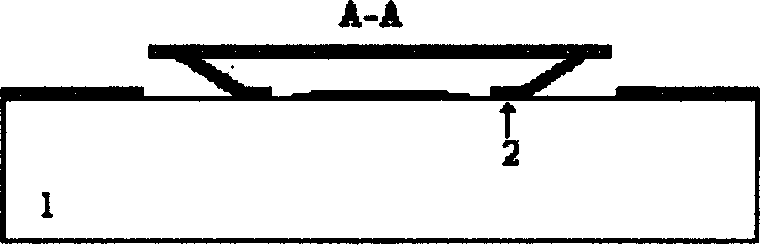

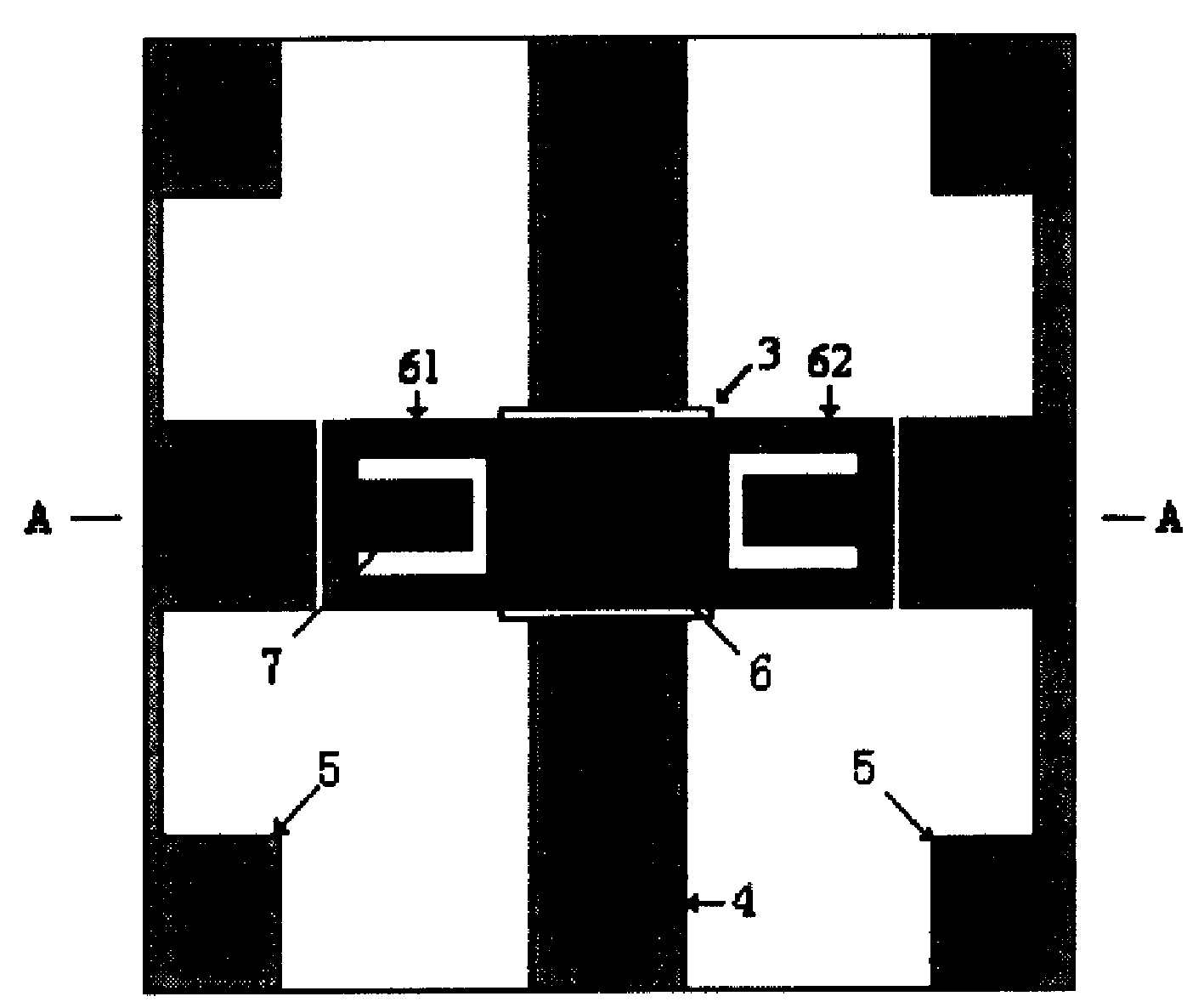

[0008] A capacitive micromechanical switch used in a microelectromechanical system, comprising: a semiconductor substrate 1, on which a bridge pier 2, a coplanar waveguide signal line 4, a ground plane 5 and a flat film beam 6 are arranged. The coplanar waveguide signal line 4 below the flat membrane beam 6 is provided with an insulating dielectric layer 3, and concave notches 61 and 62 are provided at both ends of the flat membrane beam 6, and the bridge pier 2 connects with the flat membrane beam 7 through a "T" shape. The notch ends of the beams 6 are connected. When a DC control voltage is applied, the flat membrane beam deflects under the action of electrostatic force. When the DC voltage increases to a certain value, the flat-membrane beam is in contact with the insulating layer. At this time, a large coupling capacitance is formed between the flat-membrane beam and the coplanar waveguide signal line, the signal is reflected, and the switch changes from "on" For "off" s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com