Locking machanism for cargo ship hatch cover storing device

A technology for locking mechanisms and cabins, applied to ship hatches/hatches, ship parts, ship construction, etc., can solve insurmountable problems and achieve simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

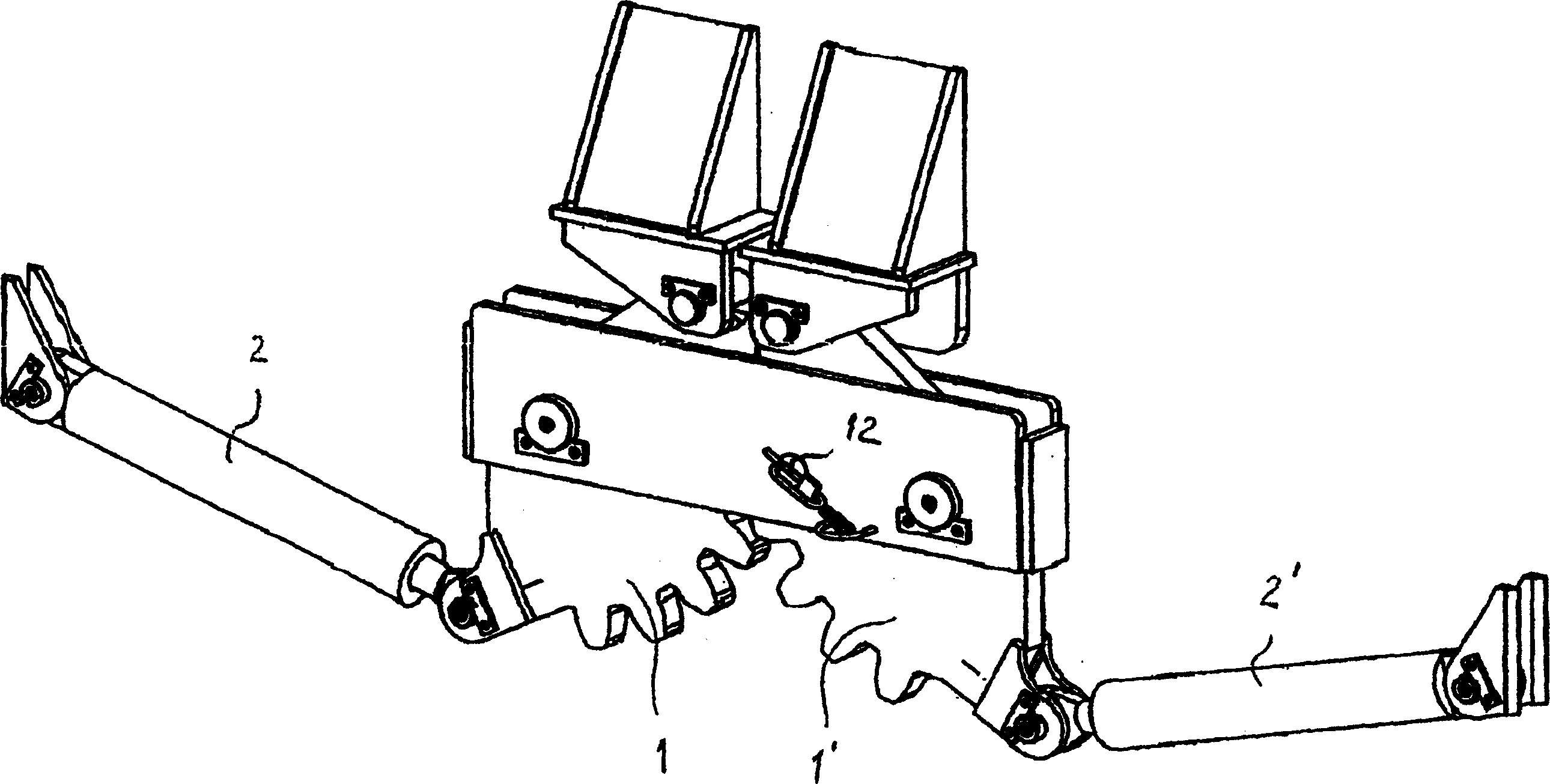

[0013] refer to figure 1 , which shows a conventional hatch cover storage device and its locking mechanism. Therein, a single drive cylinder 2, 2' is connected to two meshing sector gears 1, 1'. Therefore, the movement of the sector gear is achieved by means of the drive liquid cylinder connected to the sector gear. However, this construction requires a separate locking pin 12 in order to secure the sector gear in its lower position (ie the closed position of the hatch panel end). Thus, the locking pins are used to prevent the hatch cover ends from opening at sea.

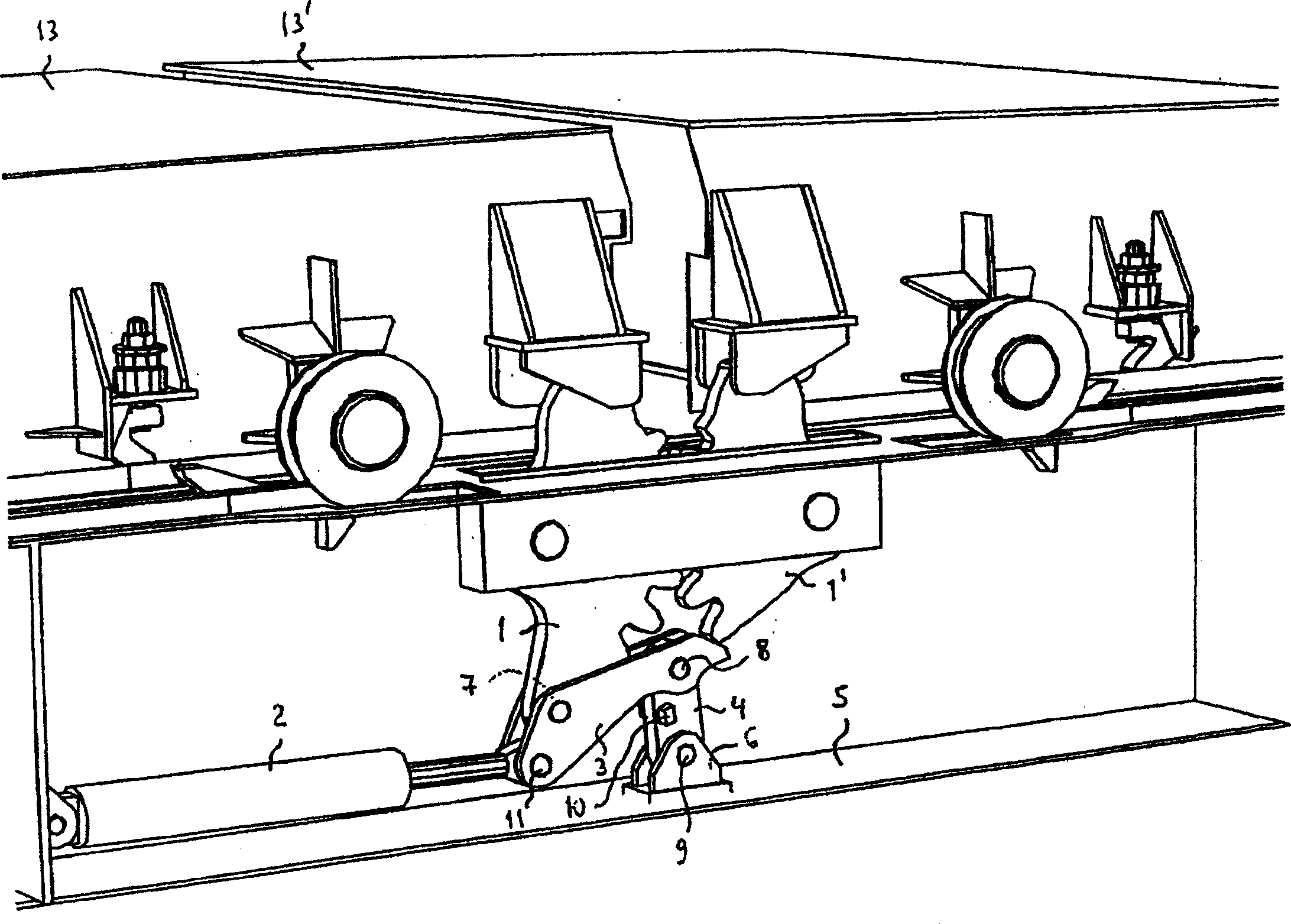

[0014] exist figure 2 shows the hatch cover storage device according to the present invention, the hatch cover storage device adds a triangular plate 3 between the sector gear 1 and the drive cylinder 2, and the triangular plate is also connected to the On the hinged eye plate 6 on the hull 5. Thus, the triangular plate 3 has three support / pivot points 7, 8, 11, where pivot point 7 is the pivot point between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com