Rocker arm for valve train in internal combustion engine with device for independent setting/adjust ment of valve play

A technology of valve clearance and valve mechanism, which is applied to valve devices, engine components, machines/engines, etc., and can solve problems such as high manufacturing cost, dependent response time, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

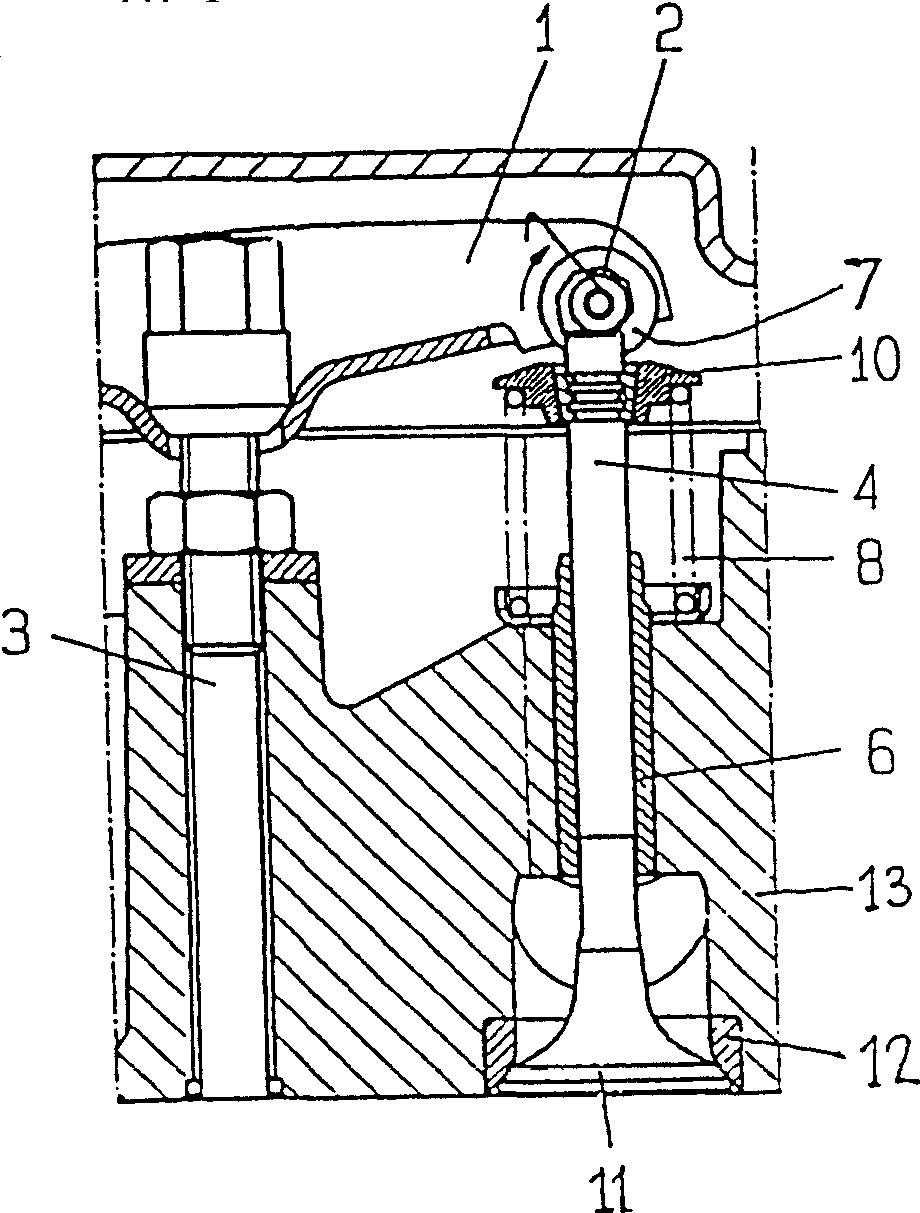

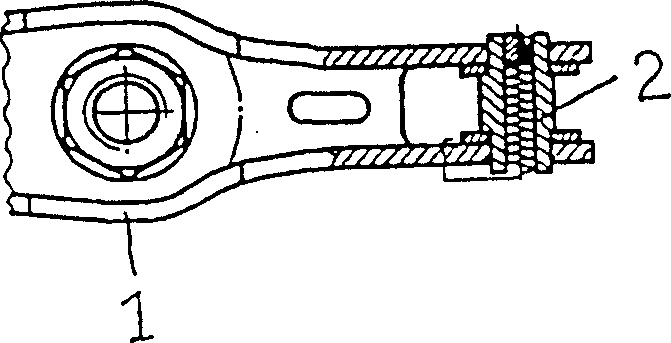

[0043] Depend on figure 1 It can be seen that the rocker arm 1 according to the invention is brought into contact with the valve rod end of the valve rod 4 via the slider 2 . The valve stem 4 is movably mounted in the valve stem guide sleeve 6 . The valve stem 4 is pressed by the valve spring 8 into a position in which the valve head 11 is in sealing contact with the valve seat 12 . The valve spring 8 bears on the one hand on the cylinder head 13 and on the other hand on a spring plate 10 fastened to the valve stem. The rocker arm 1 is fixed on the engine block by a rod 3 . The slider 2 is rotatably mounted in a corresponding notch at one end of the rocker arm 1 and is located between the spacers 7 . On the upper edge of the rocker arm 1 is a fixed bearing of a torsion spring 5 which rotates the slider 2 .

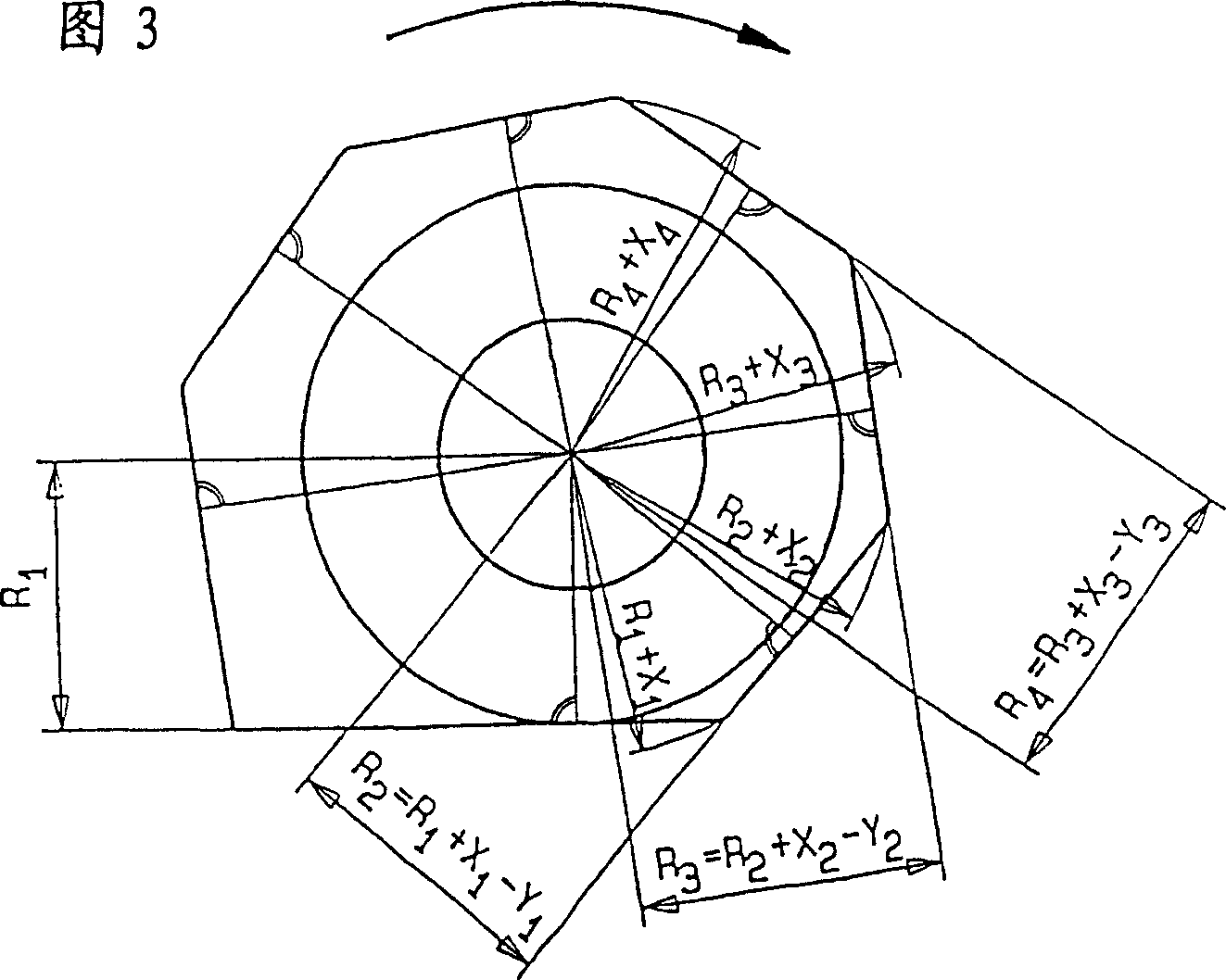

[0044] In the basic position of the slider 2, the flat surface on the slider with the smallest and shortest distance, ie the flat surface with the shortest perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com