Connection structure for inserting terminal of distribution board and earthing copper rod terminal

A technology for connecting structures and grounding terminals, applied to grounding devices, substations/switchgear boards/panels/desks, electrical components, etc., can solve troublesome problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

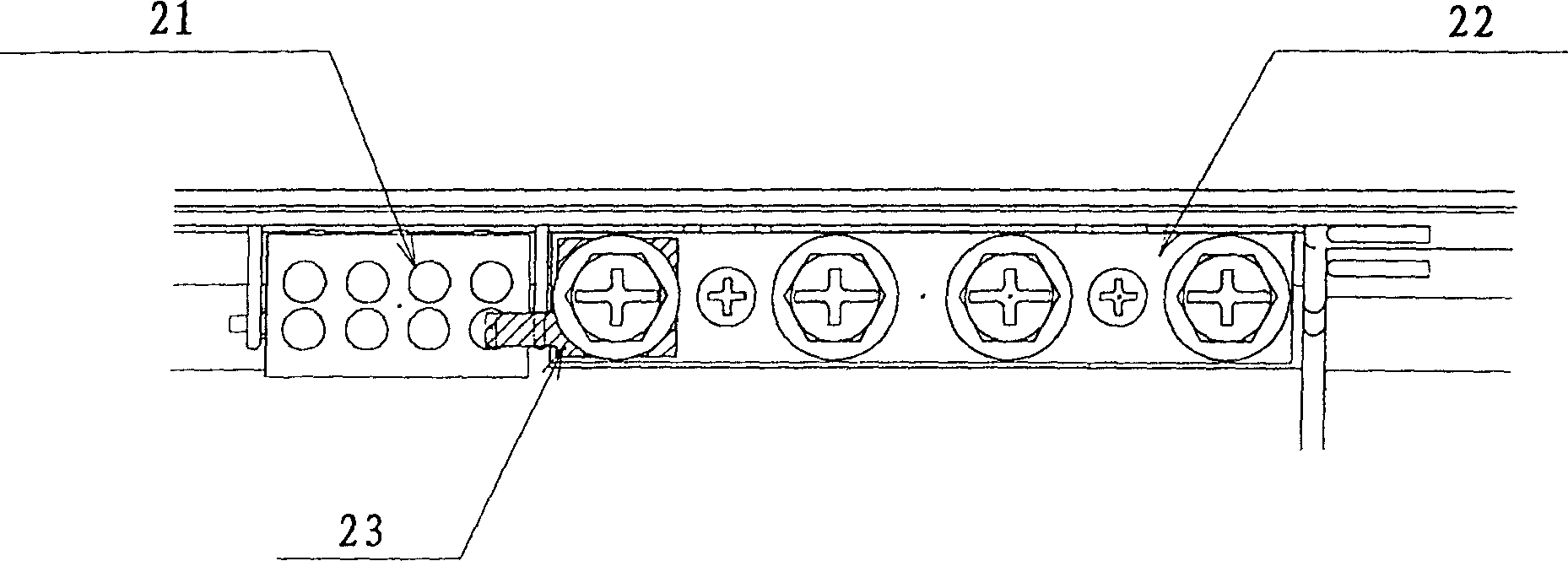

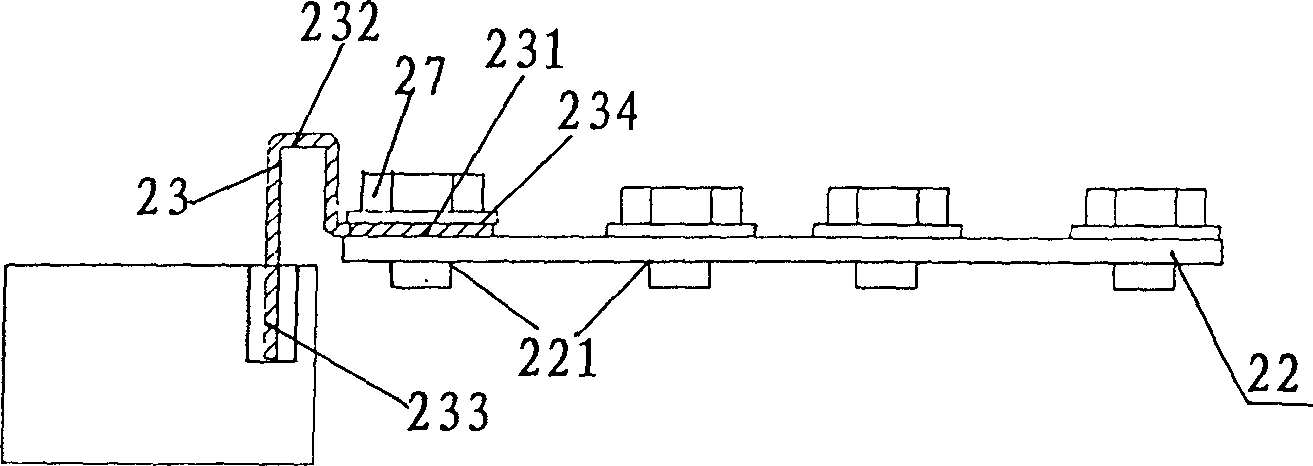

[0015] like Figure 2A , Figure 2B As shown, the insertion terminal portion 21 of the switchboard is constituted by a plurality of holes, and a plurality of through holes 221 are drilled in the copper rod portion 22 of the switchboard. In addition, the conductor 23 for electrically connecting the insertion terminal portion 21 and the copper rod portion 22 is formed by bending, and when viewed from the cross-section thereof, it is formed substantially " ” shape. In addition, a through hole 234 is drilled in the long horizontal plate 231 of the conductor 23, in the state where the through hole 221 and the through hole 234 are aligned, the screw 27 is inserted from the upper direction, the screw 27 is tightened, and the connection with the copper rod is completed. 22. In addition, when the long vertical plate 233 of the conductor 23 is inserted into the insertion termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com