Method for detecting the position of components placed on a substrate by pick-and-place robot

An identification method and automatic technology, applied in the direction of electrical components, electrical components, etc., can solve the problem that the substrate can no longer be used without considering the elimination of errors, and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

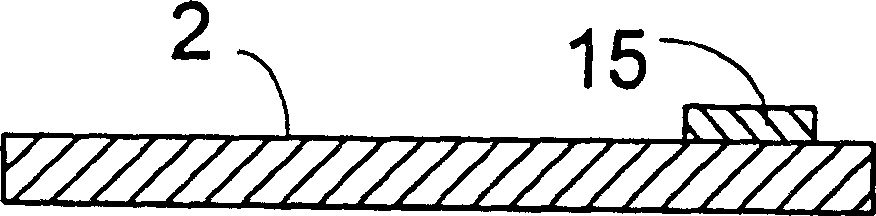

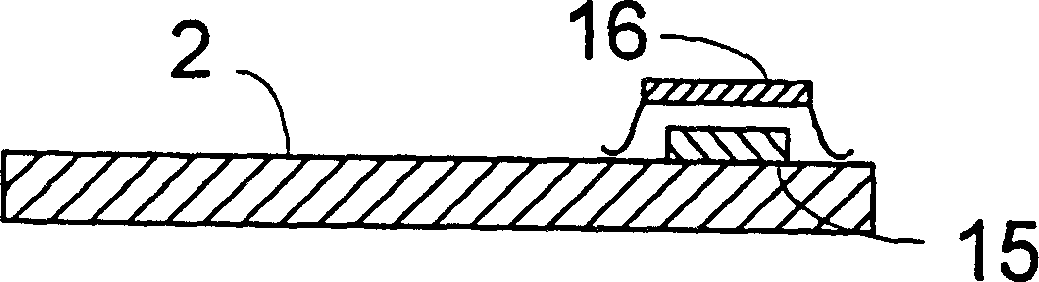

[0023] By means of the automatic inserting machine 1 shown in FIG. 1 and by means of a holder device 5 (such as a straw), the device 15 is taken out of a conveying unit not shown and positioned on the substrate 2 at a predetermined position. At this time, the substrate 2 is transferred on the automatic inserting machine by means of the transfer device 3. The support device 5 is fixed on the fixing device 6 on the inserting head 4 of the automatic inserting machine 1, and the inserting head-monitored by the control device 7-moves in the x-y-direction parallel to the substrate 2. Therefore, all positions of the substrate 2 can be reached. For example, a sensor 10 composed of an optical detector 11, an optical imaging device 12, and an image processing unit not shown, for example, which can be installed in a control device, acquires at least part of the inserted device 15 in its field of view 13. If the sensor 10 is fixed on the insertion head 4, its field of view 13 can reach every ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com