Free flow electrophoresis apparatus

An electrophoretic device, a carrier-free technology, applied in the direction of measuring devices, solid separation, electrostatic effect separation, etc., can solve the problems of increasing the length of the electrode, manufacturing the separation chamber gap, increasing the external size of the separation chamber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

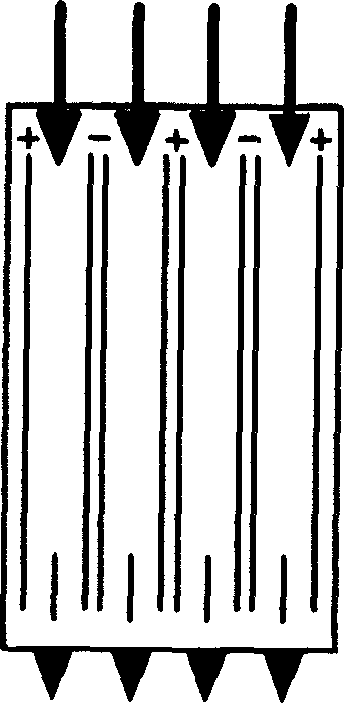

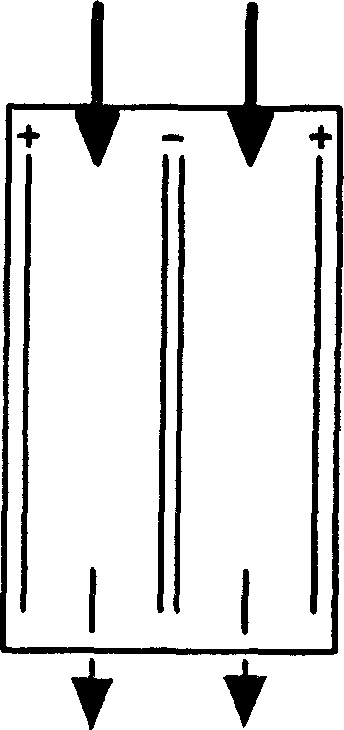

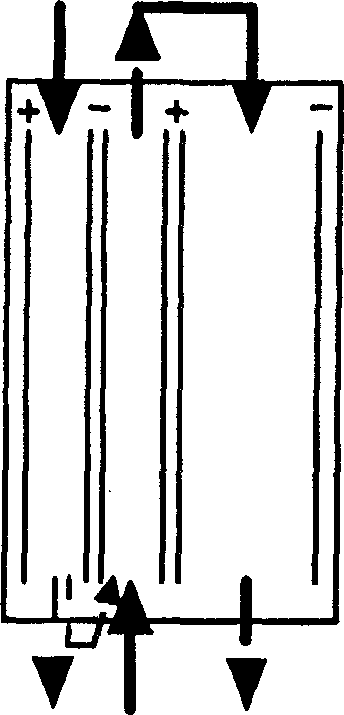

[0020] Three examples of separation chambers in different embodiments of an electrophoretic device according to the invention are schematically represented in FIGS. 1 , 2 and 3 . In order for the separation chamber to have external dimensions which allow machining of the separation chamber gap with the necessary precision, a plurality of separate separation spaces are provided in the separation chamber. According to FIG. 1 , there are four separate separation spaces with four separate medium inlets and four separate classification sections, each classification section having n classification positions, where n is less than 15. FIG. 2 shows a separation chamber with two separate separation spaces and two separate medium inlets, each with n classification positions, where n is greater than 50, on the two separate classification sections. Finally Fig. 3 shows a separation chamber with three separate separation spaces, three separate medium inlets, two classification sections with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com