Fluid compression apparatus

A technology for compressing equipment and fluids, applied in mechanical equipment, components of pumping devices for elastic fluids, liquid fuel engines, etc., can solve problems such as lack of good manufacturing methods, increased manufacturing costs, and reduced fluid volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

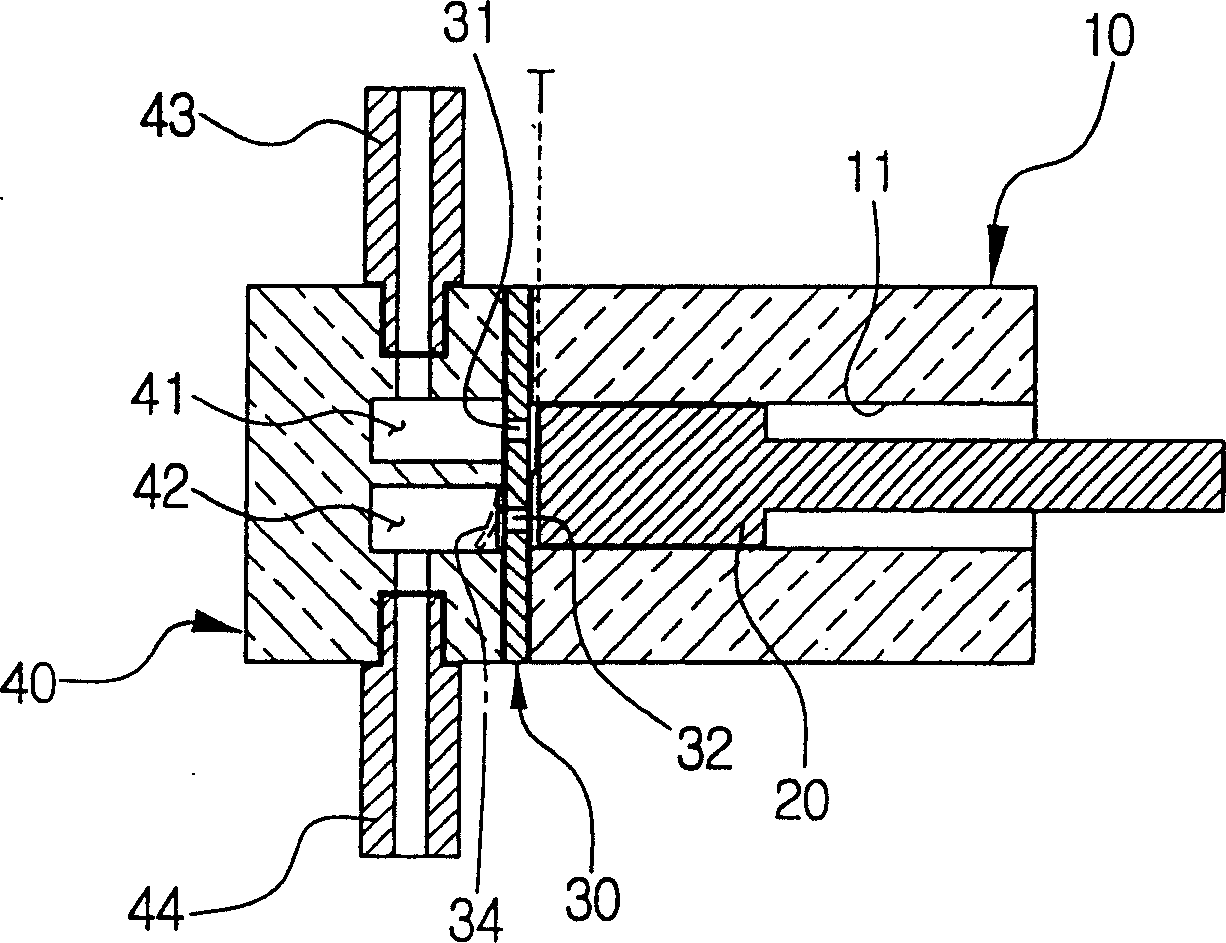

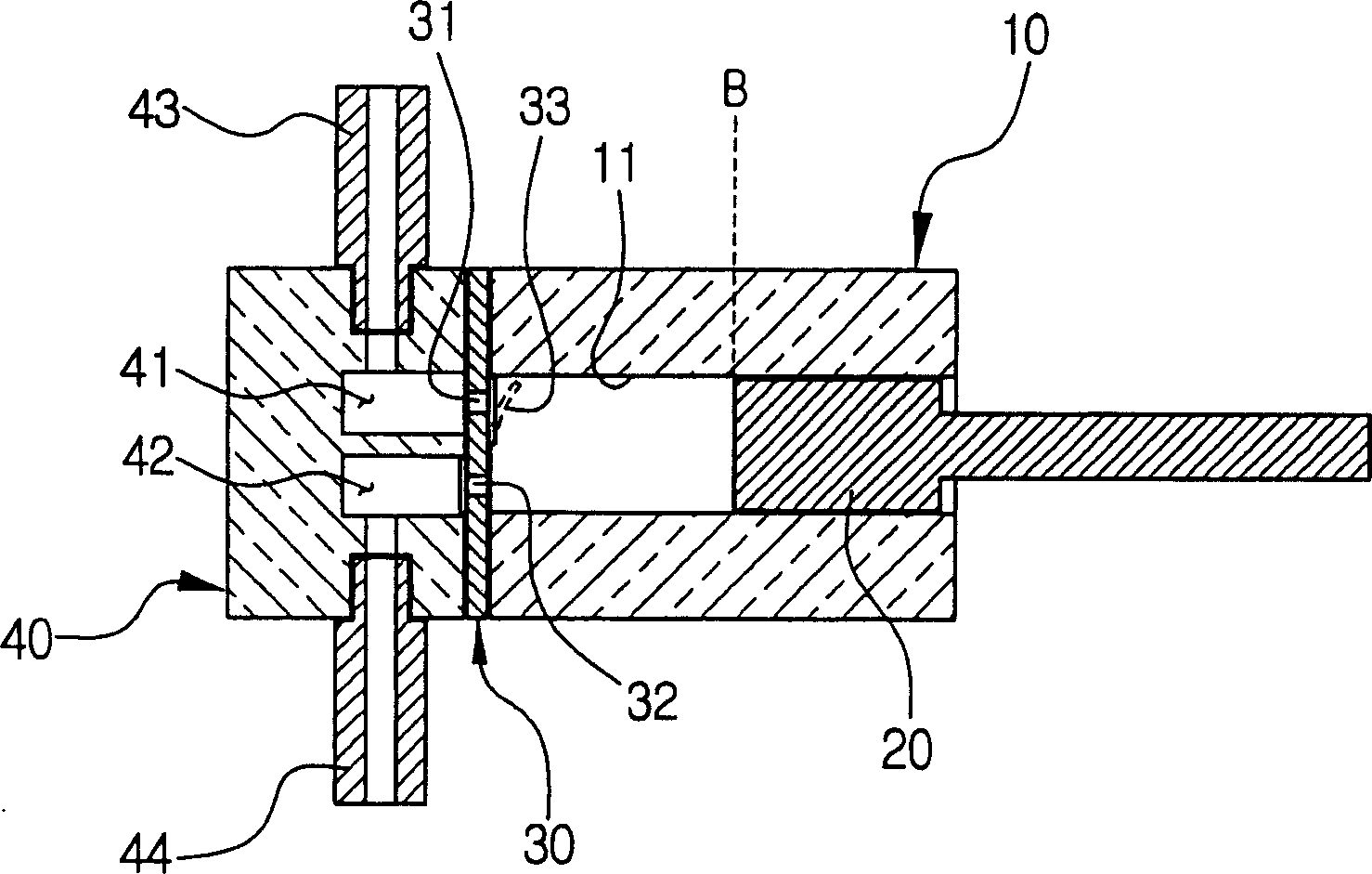

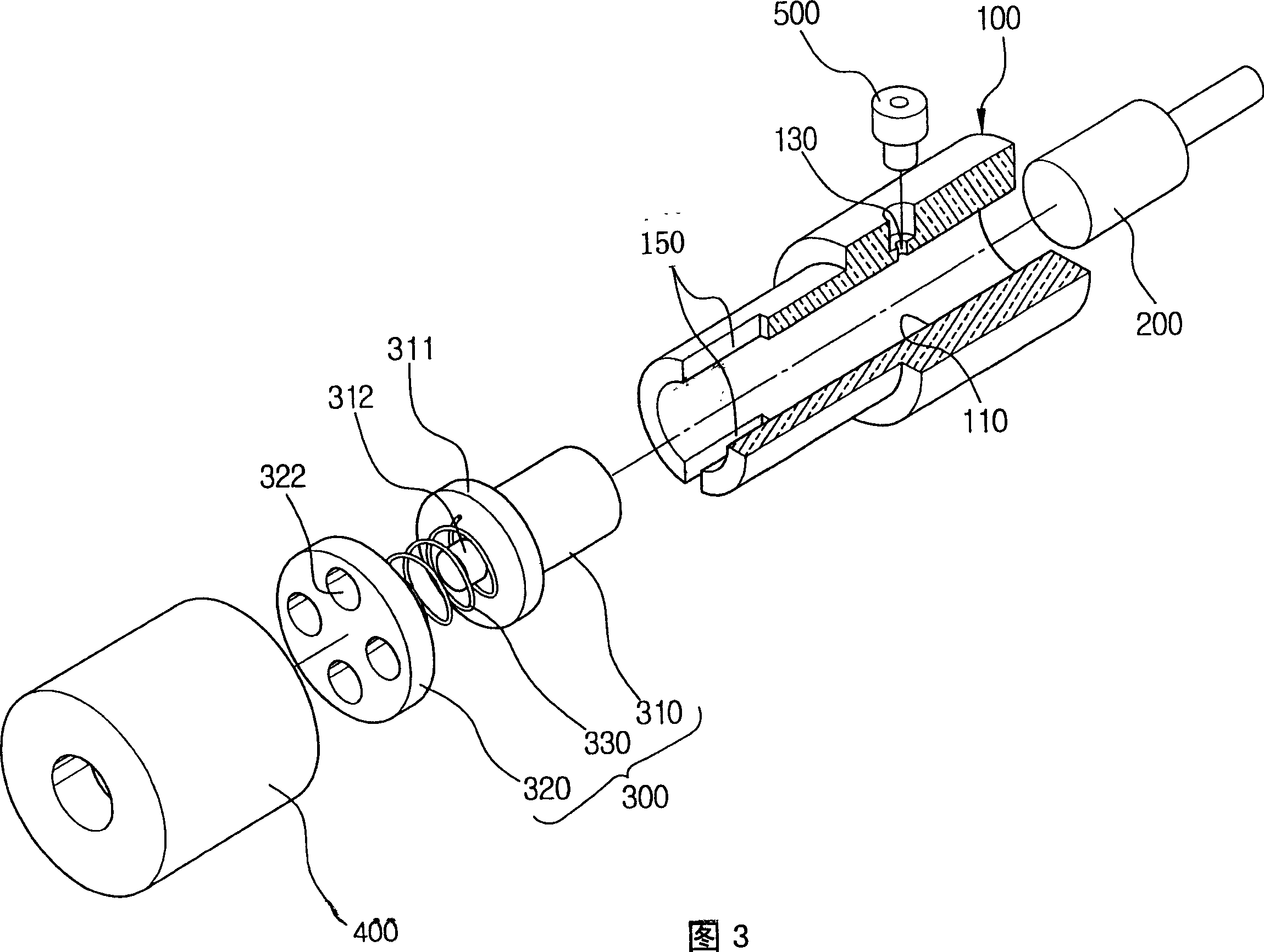

[0031] Fig. 3 is a cutaway exploded perspective view showing a fluid compressing device according to a first preferred embodiment of the present invention. Figure 4 to Figure 6 is a sectional view illustrating the result and operation of the fluid compressing apparatus according to the first preferred embodiment of the present invention shown in FIG.

[0032] Figure 3 to Figure 6 As shown, the fluid compression device according to the present invention includes a cylinder 100 , a piston 200 , a discharge valve assembly 300 and a cylinder head 400 .

[0033]The cylinder block 100 includes a cylinder bore 110 having a predetermined diameter and passing through the cylinder block 100 longitudinally, at least one fluid suction port 130 passing through the cylinder bore 110 at a right angle with respect to the cylinder bore 110, at least a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com