Push flow composite biological mud volume reducing reactor and its operation method

A technology of biological sludge and operation method, applied in biological sludge treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as ineffective sludge reduction and unstable growth of metazoans, and achieve Easy to automate control, reduce sludge treatment and disposal costs, improve sludge settling and dewatering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

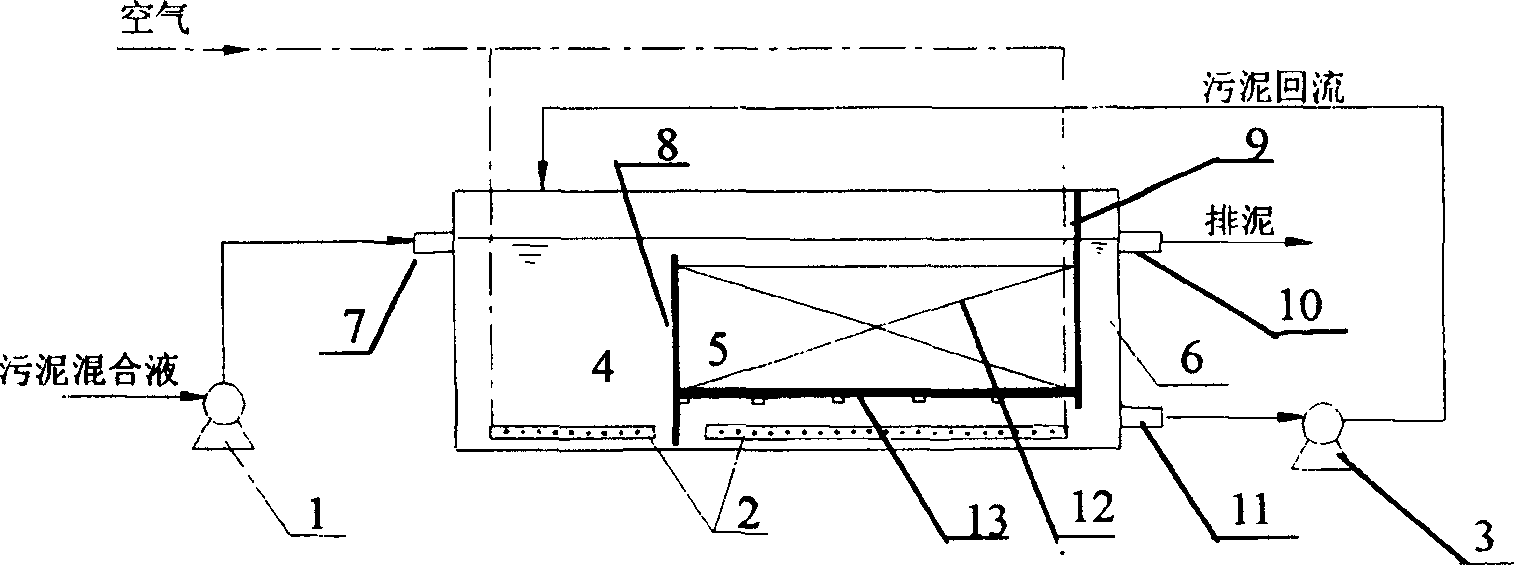

[0042] The push-flow composite biological sludge reduction reactor is divided into three parts by a partition. They are free type protozoa, metazoan growth area, attached type protozoa, metazoan growth area, and solid-liquid separation sedimentation area, which are used for sewage organisms. Reduce the amount of surplus sludge discharged from the treatment system.

[0043] Use a sludge transfer pump to transfer the remaining sludge discharged from the secondary settling tank or sludge thickening tank in the sewage treatment plant to the free-type protozoan and metazoan growth area of the push-flow composite biological sludge reduction reactor, and then Enter the attached protozoan, metazoan growth area and solid-liquid separation sedimentation area in turn. During the entire operation, keep the water temperature in the push-flow composite biological sludge reduction reactor at 20°C and the pH at 6-9, and the activated sludge concentration in the free-form prot and metazoan growt...

Embodiment 2

[0047] The push-flow composite biological sludge reduction reactor is divided into three parts by a partition. They are attached protozoa, metazoan growth area, free protozoa, metazoan growth area, and solid-liquid separation sedimentation area, which are used to treat conventional The return sludge of the activated sludge method is integrated with the aeration tank and the secondary settling tank to reduce the amount of sludge produced.

[0048] Use a sludge transfer pump to transport the returned sludge mixture to the attached protozoan and metazoan growth area of the push-flow composite biological sludge reduction reactor, and then enter the free protozoan, metazoan growth area and solid-liquid separation and sedimentation in turn Area. During the entire operation, keep the water temperature in the push-flow composite biological sludge reduction reactor at 20°C and the pH at 6-9, and the activated sludge concentration in the free-form prot and metazoan growth area is 3.0-6.0g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com