Actuator using piezoelectric element and magnetic head positioning mechanism using said actuator

A piezoelectric element and positioning mechanism technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., and can solve problems such as high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

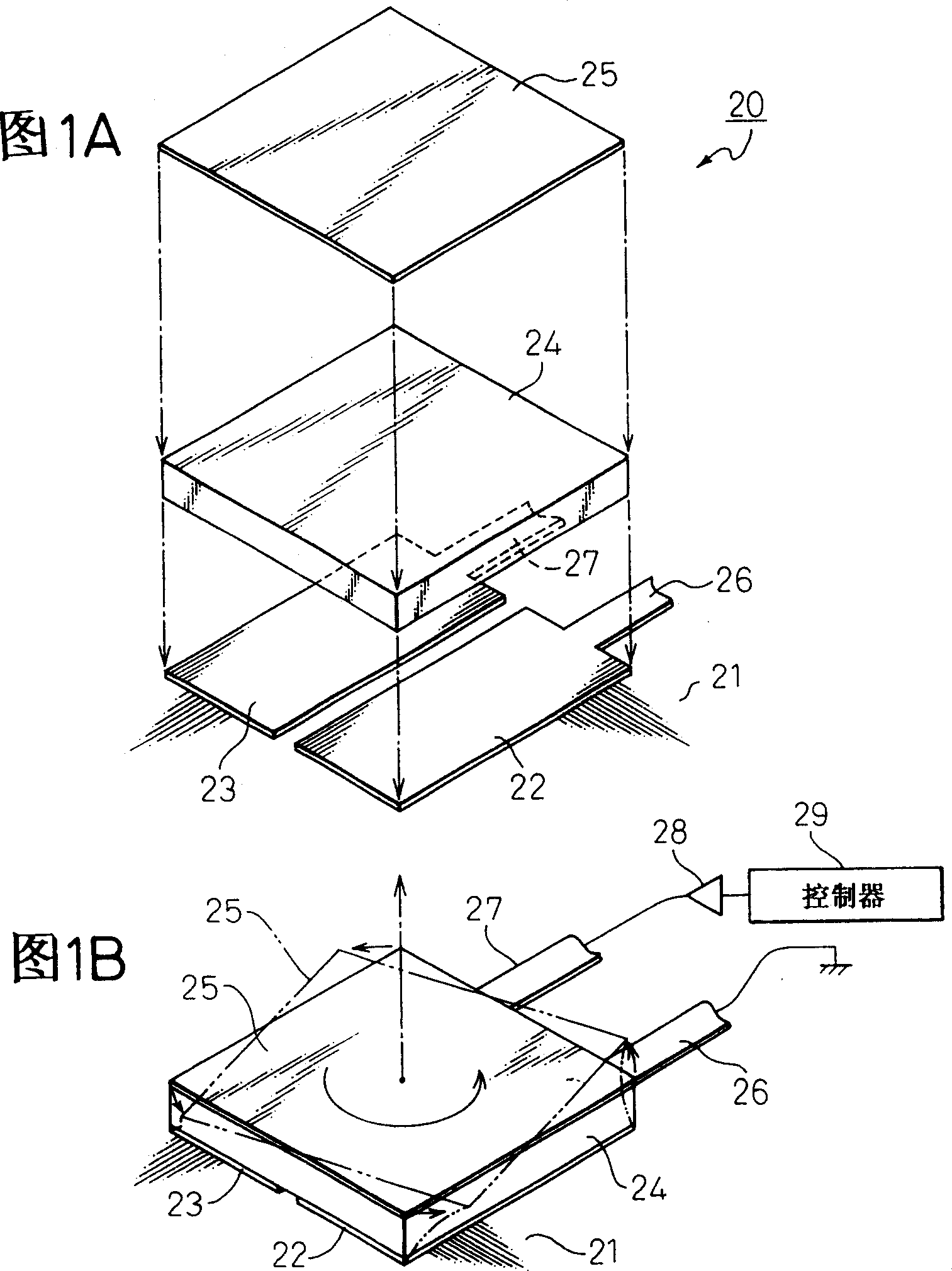

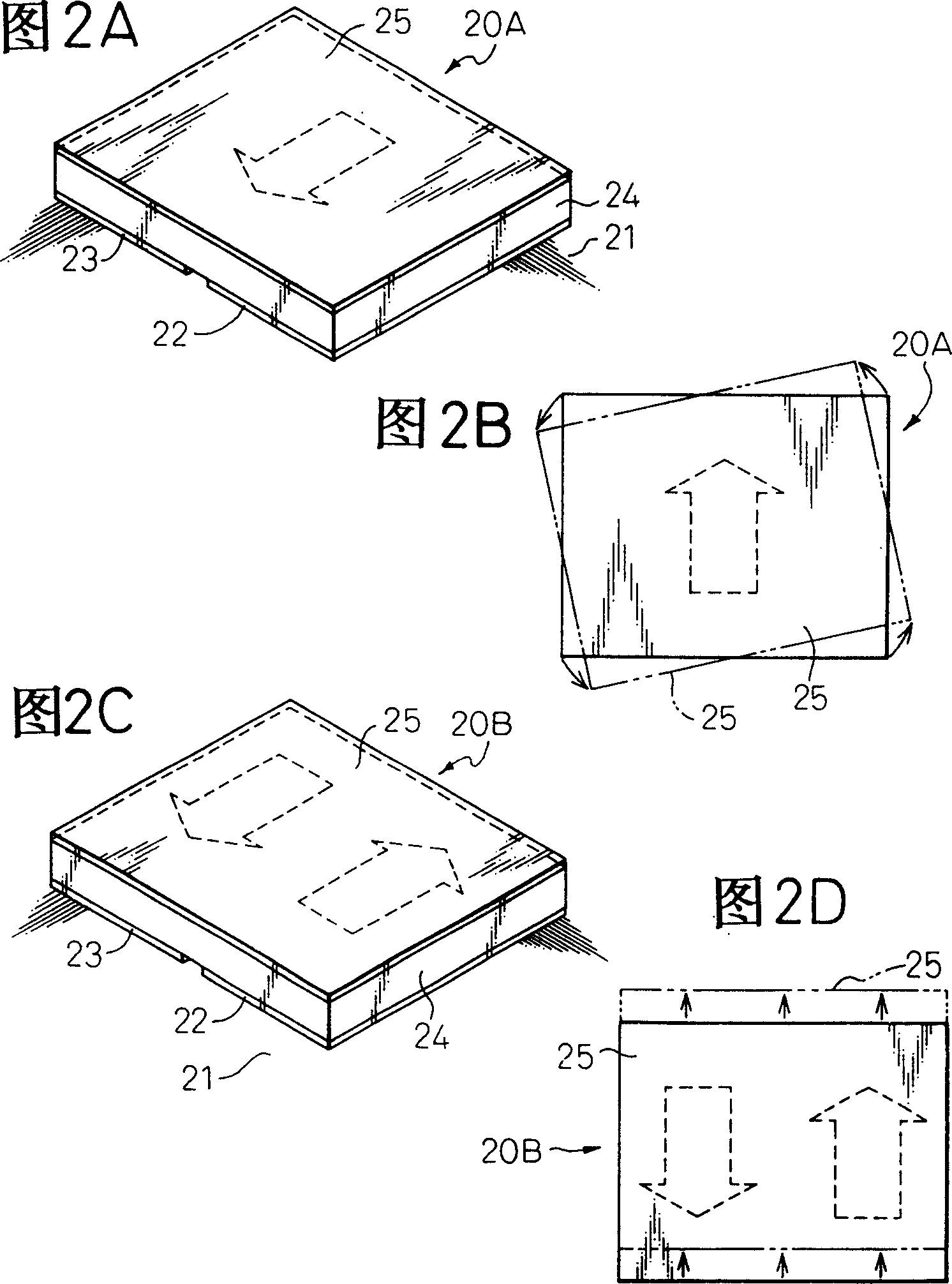

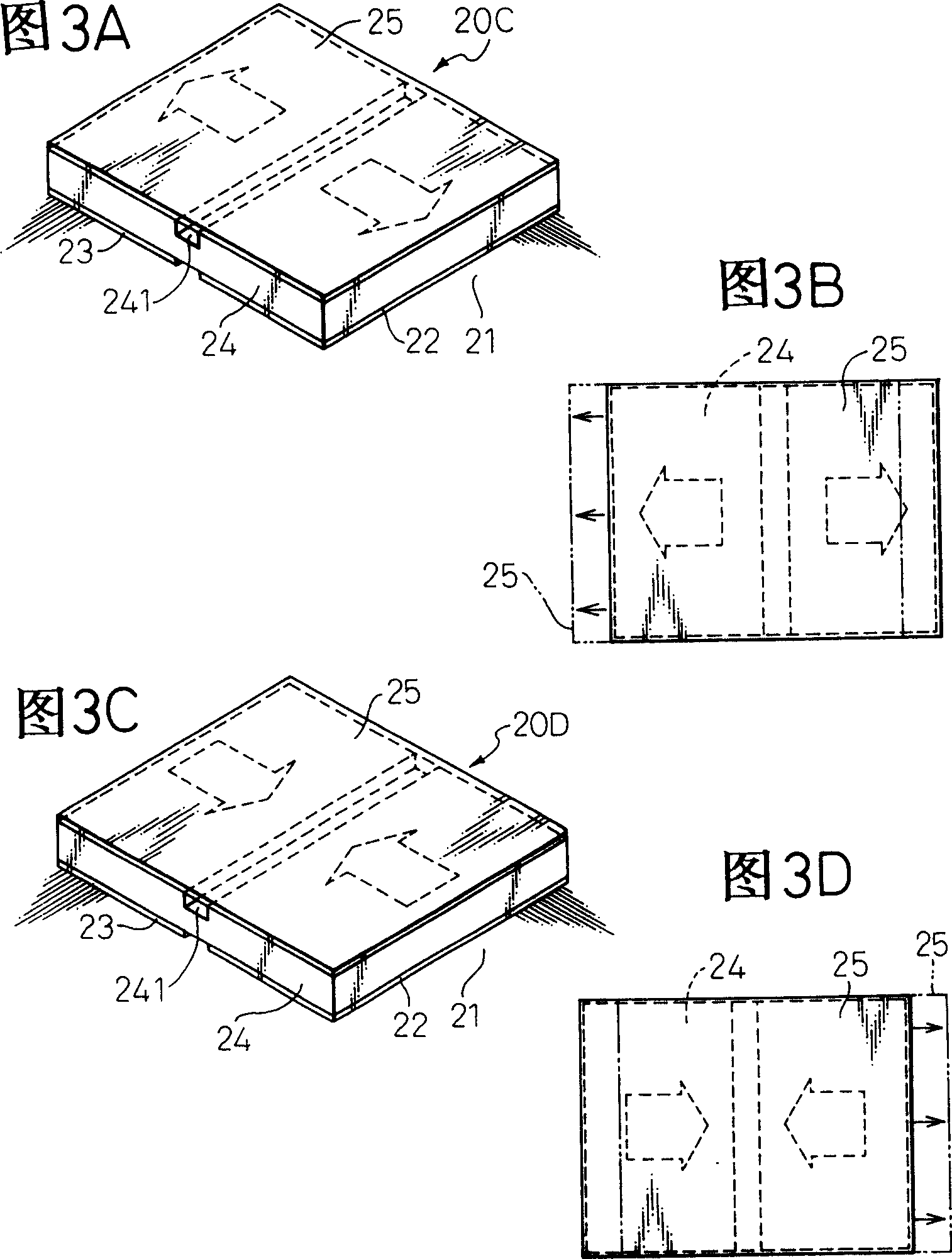

[0161] Before describing the preferred embodiment, a description with Figures 24 to 29 A common head actuator for the head positioning mechanism shown.

[0162] It has been proposed that in conventional disk drives, a second actuator which follows the magnetic track is mounted on the front end of the head actuator arm. This second actuator is capable of finely moving the magnetic head at the front end of the arm independently of the movement of the magnetic head actuator.

[0163] Figure 24 A head actuator disclosed in JP-A-3-69072 is shown, in which, in addition to the main actuator 110 of the magnetic disk drive 100, there is a sub-actuator 120 mounted on the front end of an arm 111. The sub-actuator 120 is adapted to slowly move the magnetic head 114 using two multilayer piezoelectric elements 123 . The sub-actuator 120 includes two multi-layer piezoelectric elements, and each piezoelectric element 123 is composed of a plurality of piezoelectric elements adapted to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com