Crank axle with oil-filter

A technology for oil filters and crankshafts, which is applied in the installation/connection of crankshafts, lubricant purification devices, lubricating parts, etc. It can solve the problems of increased weight and inability to ensure separation performance, so as to improve strength and prevent foreign matter from passing through the filter , The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

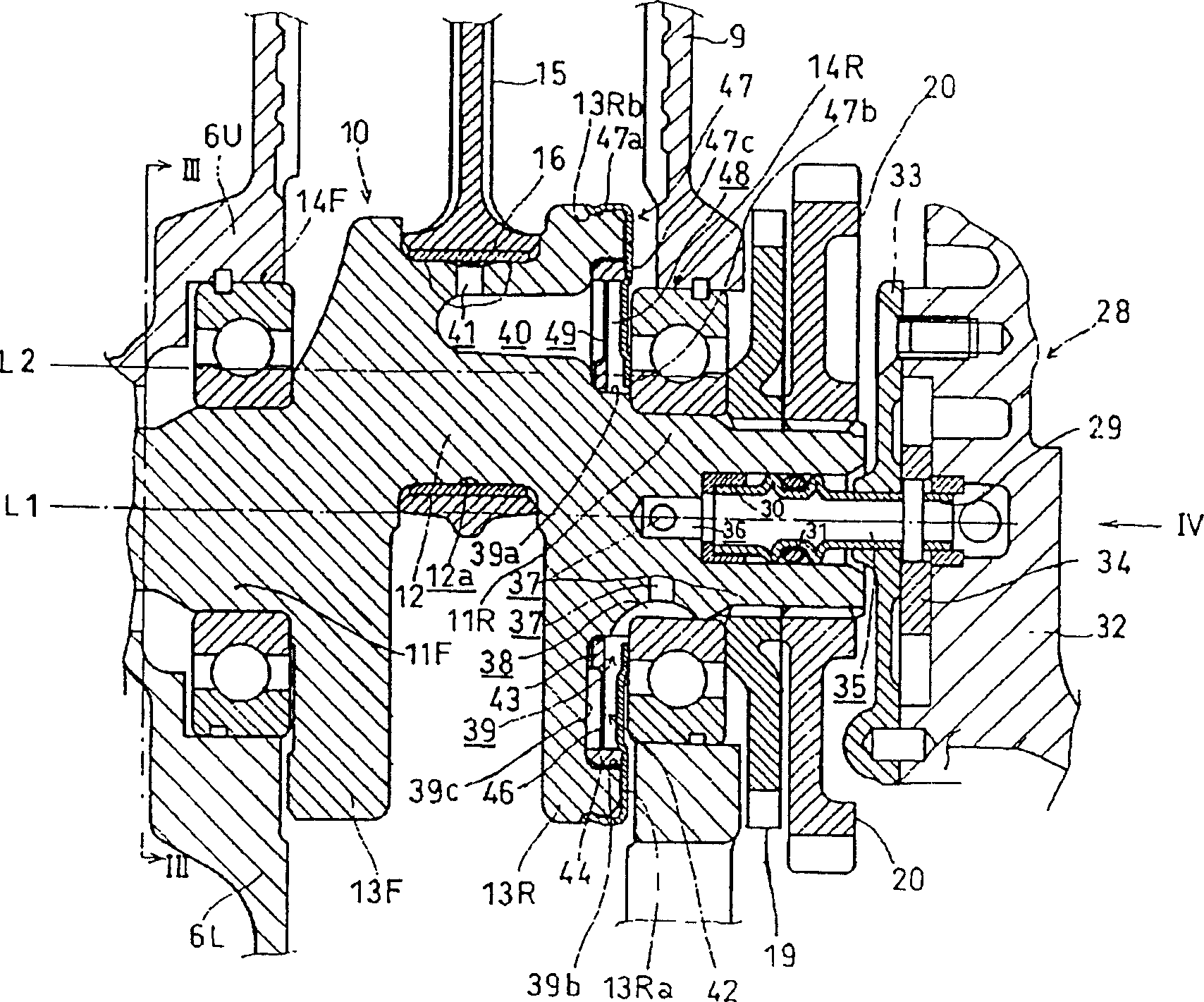

[0030] Below, refer to Figure 1 to Figure 11 , to illustrate an embodiment of the present invention.

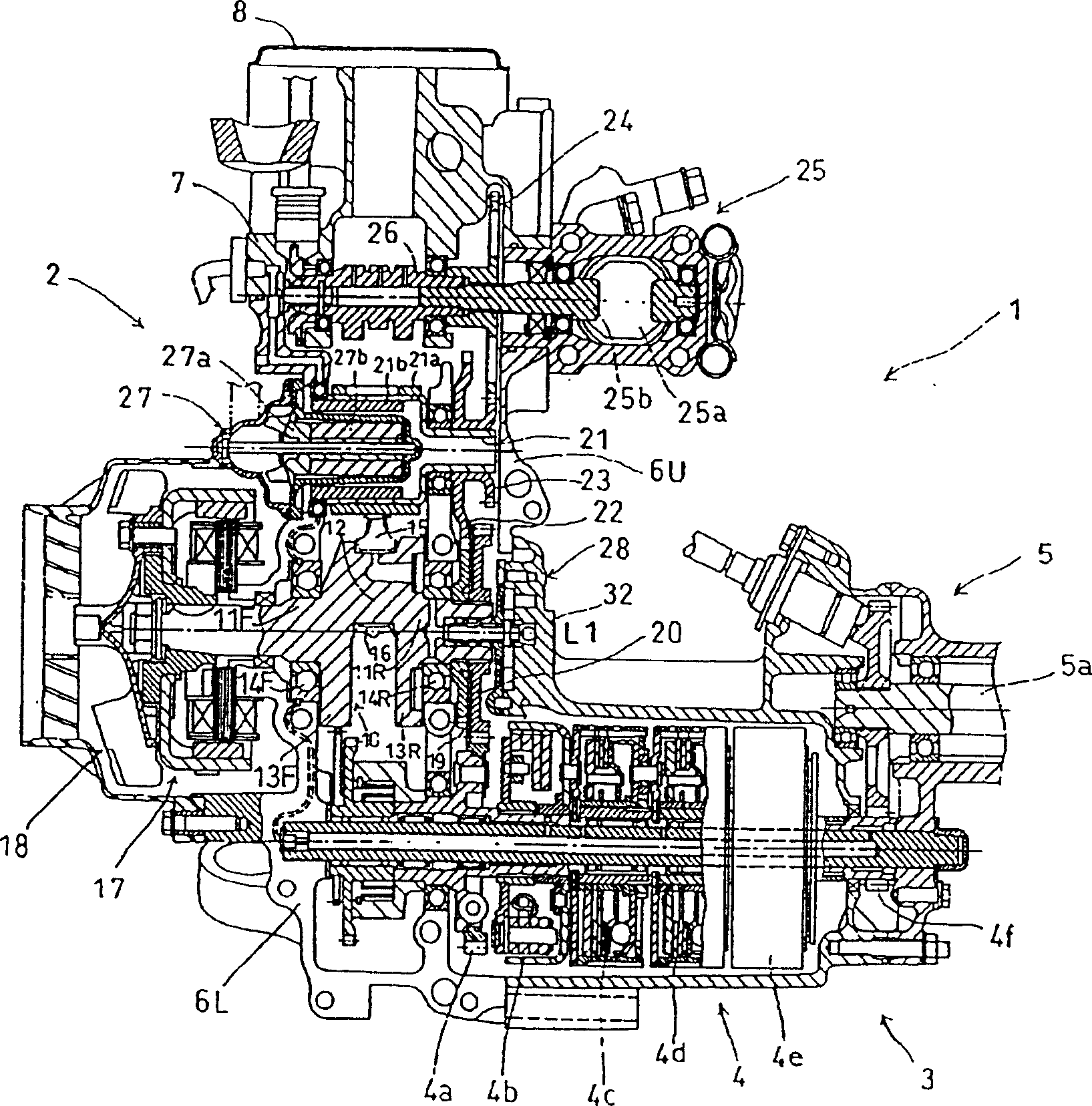

[0031] Figure 1 to Figure 6 It is a figure explaining 1st Example. figure 1 It is a planar sectional view of a power unit equipped with an internal combustion engine 2 to which the crankshaft of the present invention is applied.

[0032] The power unit mounted on the two-wheeled motor vehicle is equipped with an internal combustion engine 2 and a power transmission device 3 . The power transmission device 3 has a planetary gear type transmission 4 and a final reduction device 5 . The internal combustion engine 2 is a spark ignition type 4-stroke single-cylinder water-cooled internal combustion engine. It is composed of crankcases 6U, 6L, cylinder head 7 and cylinder head cover 8 which are divided up and down. The cylinder 9 is integrally formed on the upper crankcase 6U. upper part (see figure 2 ).

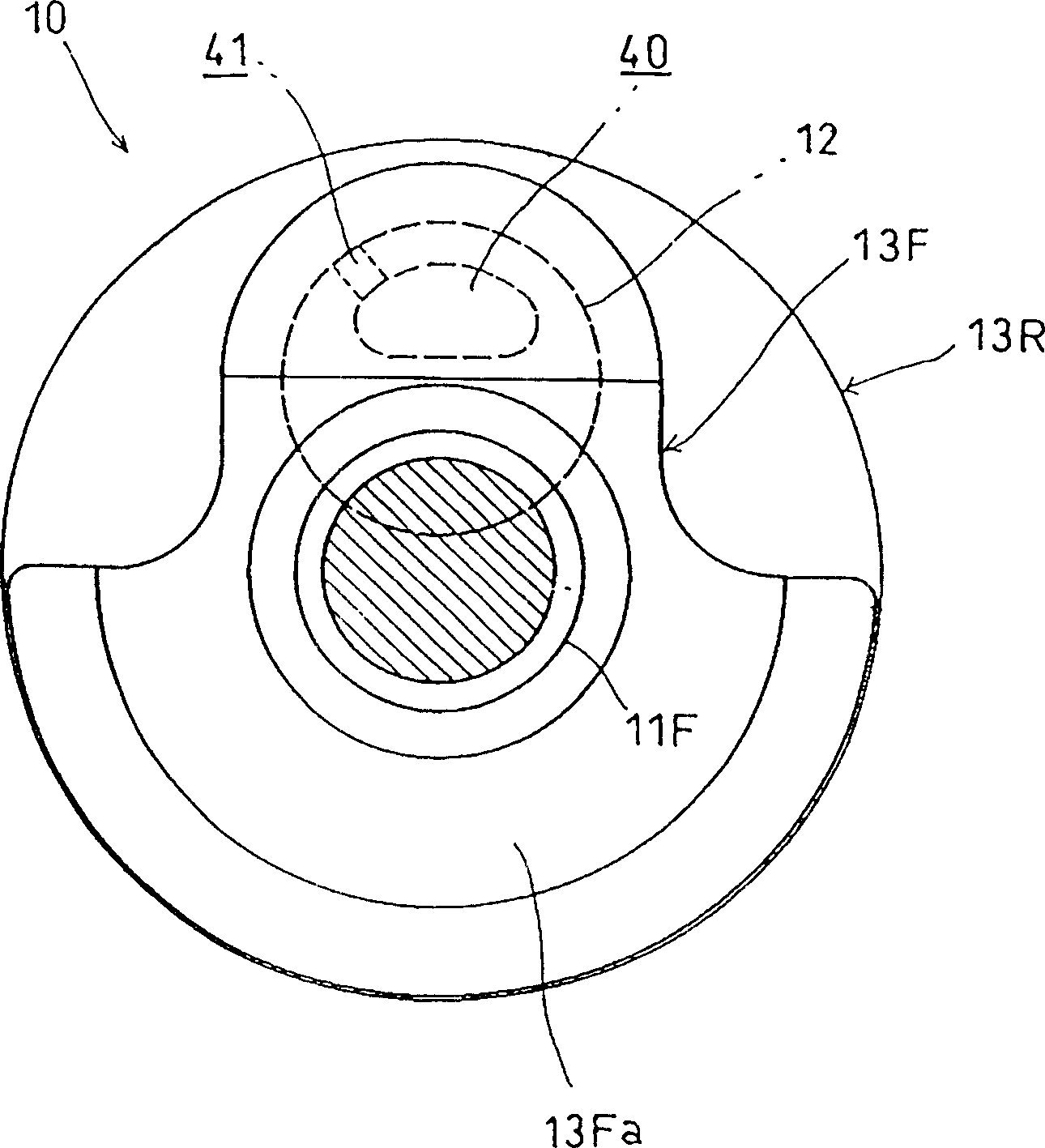

[0033] The crankshaft 10 is integrally formed by a pair of front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com