Cylindrical torsion tuning optical fiber grating sensing demodulator

A technology of sensing demodulator and fiber grating, which is used in instruments, optics, nonlinear optics, etc., to achieve the effects of good cost performance, good market prospects, and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

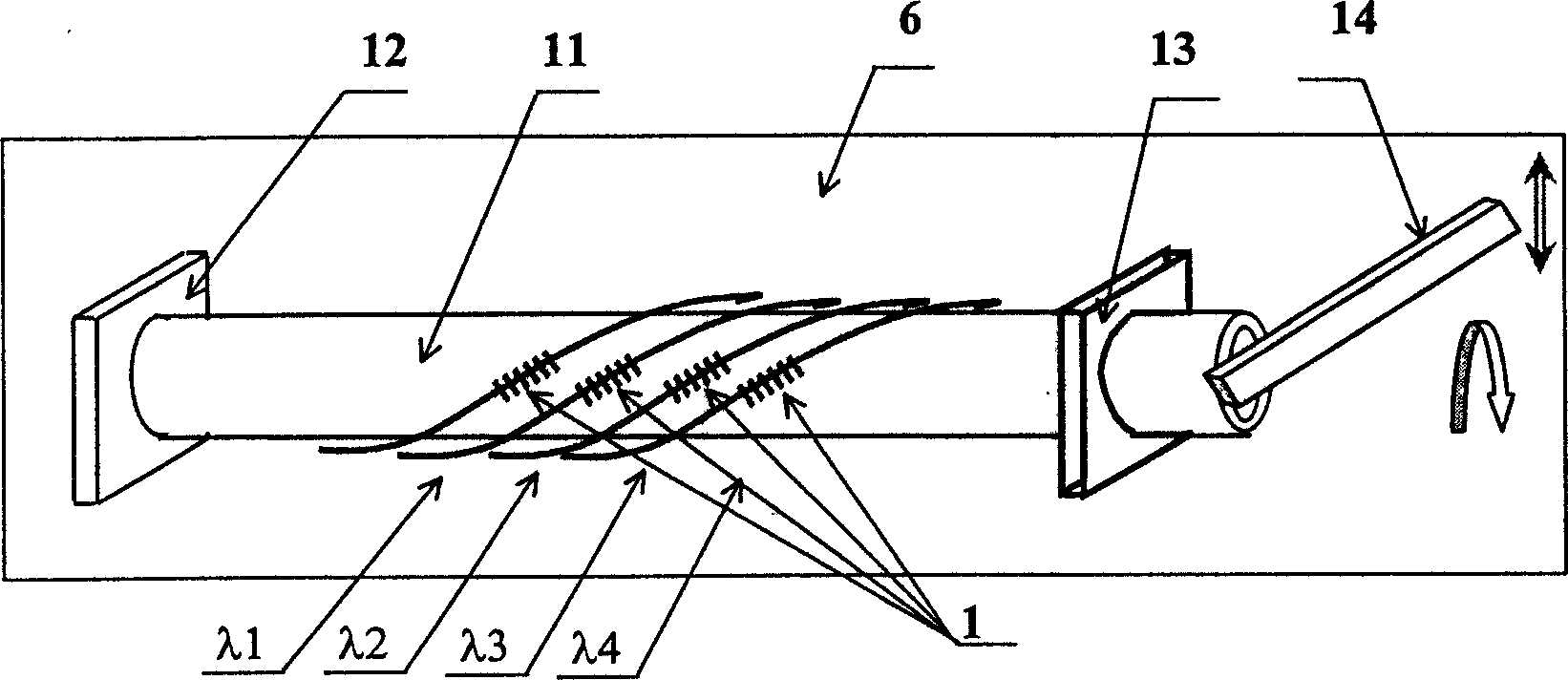

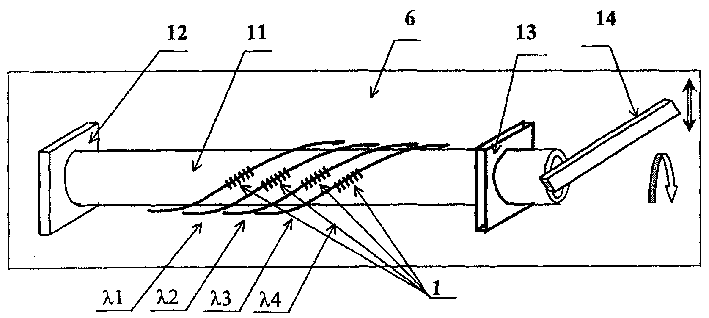

[0026] see first figure 1 , as can be seen from the figure, the fiber grating cylindrical torsion tuning sensor demodulator of the present invention pastes a fiber grating 1 on the outer surface of the cylindrical rod 11 at a certain angle; one end of the cylindrical rod 11 is fixed on the clamp 12, This end of bar is kept still; The neck of the other end (moving end) of bar is installed in the bearing bracket 13 that rotates, and the head of cylinder bar 11 moving ends is equipped with a spanner connecting rod 14, and spanner connecting rod 14 and The motor is connected; then the fixture 12, the bearing bracket 13, the motor and other parts are assembled and fixed on the casing 6 to form a cylindrical torsion tuning fiber grating sensor demodulator.

[0027] Its working process and demodulation principle are simple and clear. When the motor rotates, one end of the wrench connecting rod 14 is driven to move up and down by the connecting rod (not shown in the figure), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com