Method for monitoring radial gap between rotor and stator of electric generators and device for carrying out said method

A radial clearance and motor rotor technology, applied in the direction of adjusting/balancing rotors, electrical components, electromechanical devices, etc., can solve the problems of destroying generator downtime and not being able to provide forecasts of radial clearance real-time shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

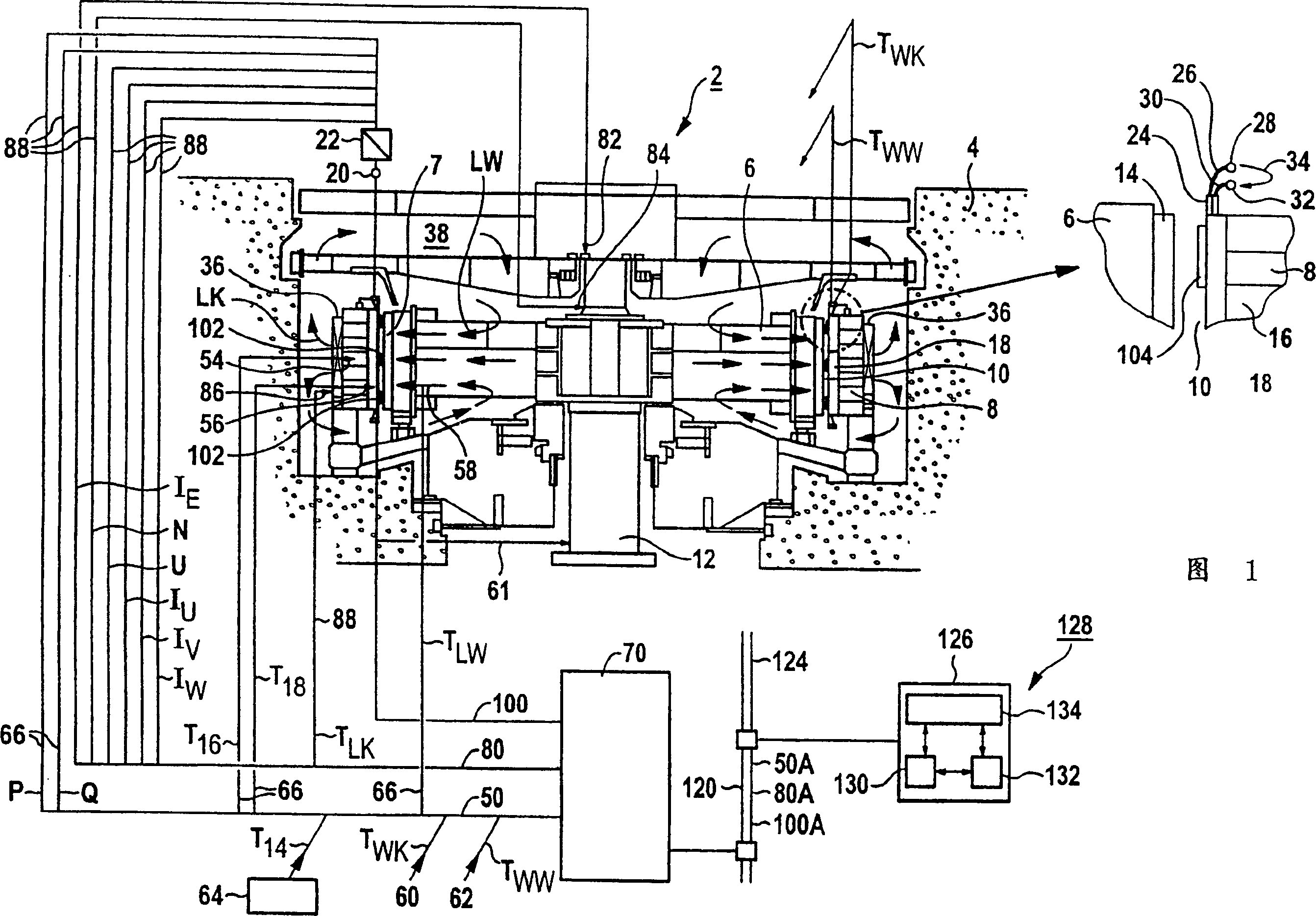

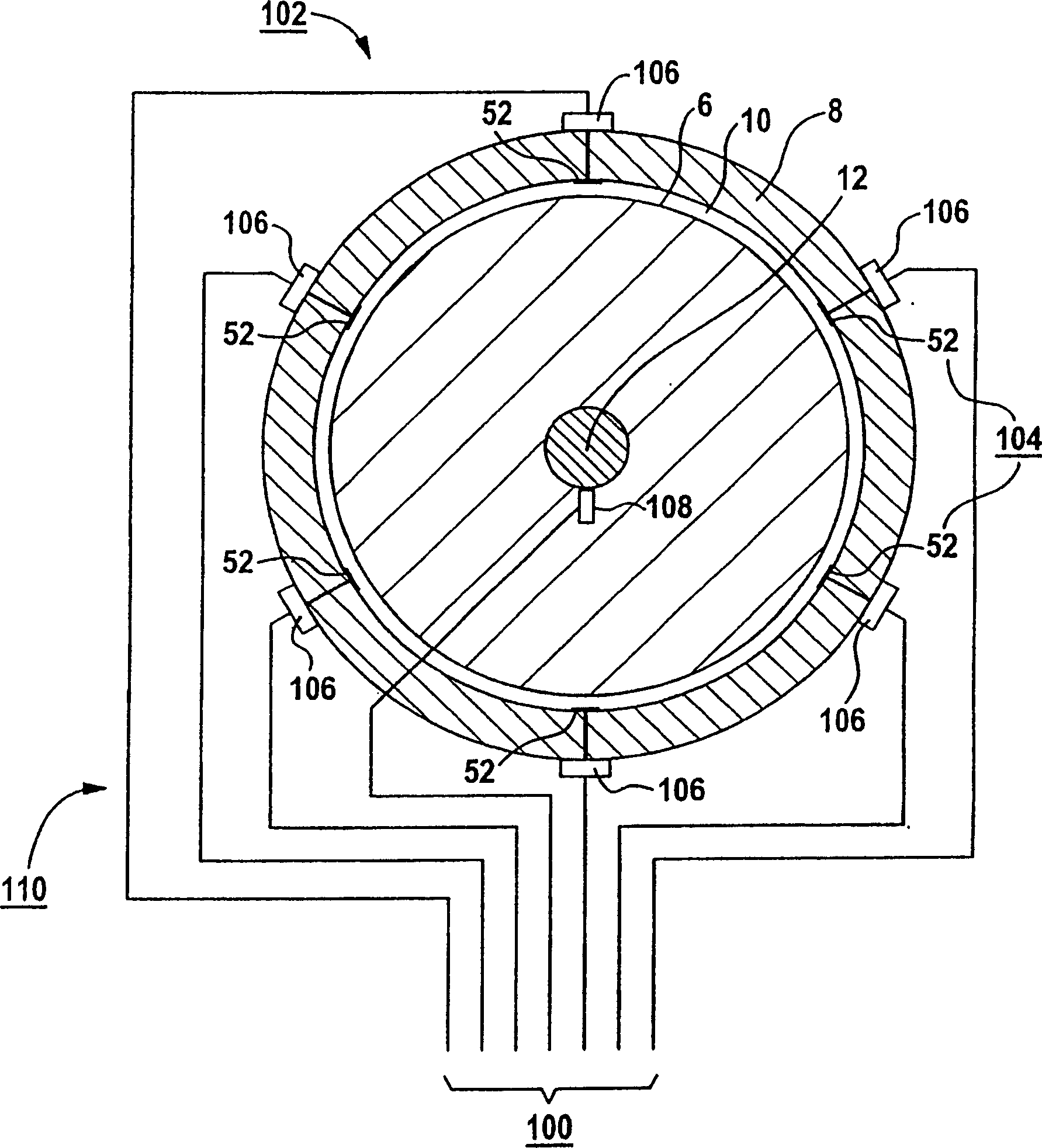

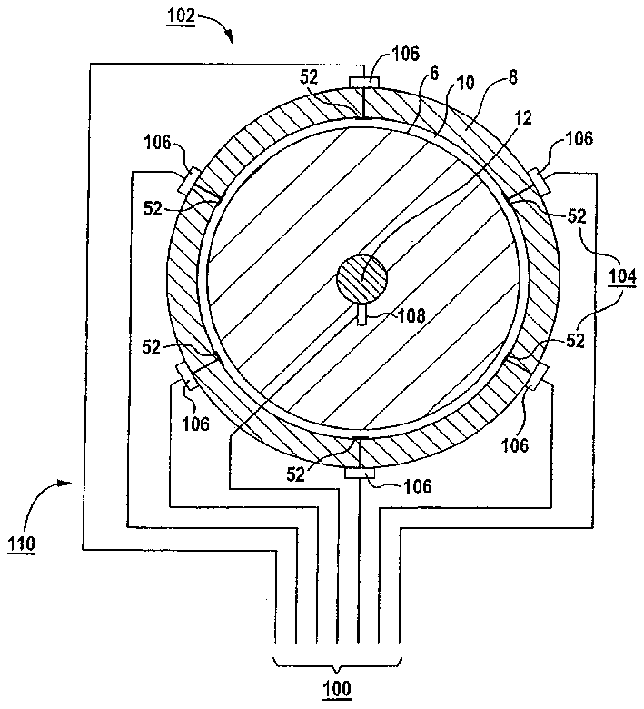

[0116] The generator 2 shown schematically in longitudinal section in FIG. 1 is designed as a hydroelectric generator and includes a rotor 6 in a housing 4 which is surrounded concentrically by a stator 8 . The rotor 6 and the stator 8 are separated from each other by a radial gap 10 . The rotor 6 includes a shaft 12, a shaft 12 for generating the excitation current I of the rotor 6 E The winding 14 and many poles not shown in detail in the figure. The stator 8 has a laminated core 16 and a winding 18 . The winding 18 of the stator 8 is connected via terminals 20 to an isolating amplifier 22 connected to a measuring circuit, which is not shown in the figure.

[0117] The winding 18 of the stator 8 comprises three separate windings U, V and W, which are not shown in this figure. The three separate windings U, V and W in turn comprise winding bars 24 connected in electrical series, only some of which are shown in the figure. When the generator 2 is in operation, cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com