U-shape seven-notch sleeve-matching method

A technology of knife eye and knife eye point, which is applied in the field of garment sewing, can solve the problems of sewing difficulty, thread yarn pulling, and inability to effectively control the balance of thread yarn direction, and achieve the effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below by way of embodiment and accompanying drawing.

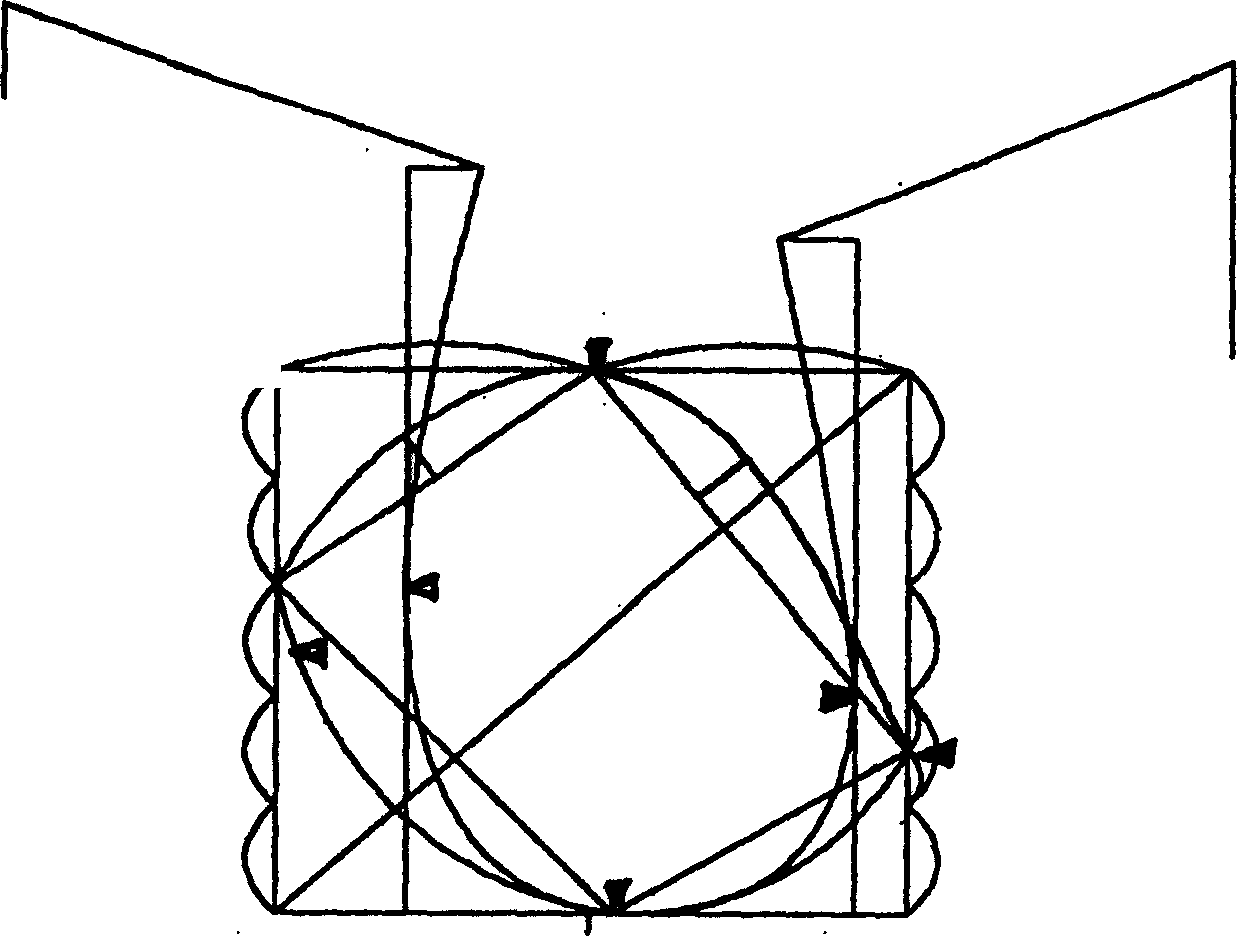

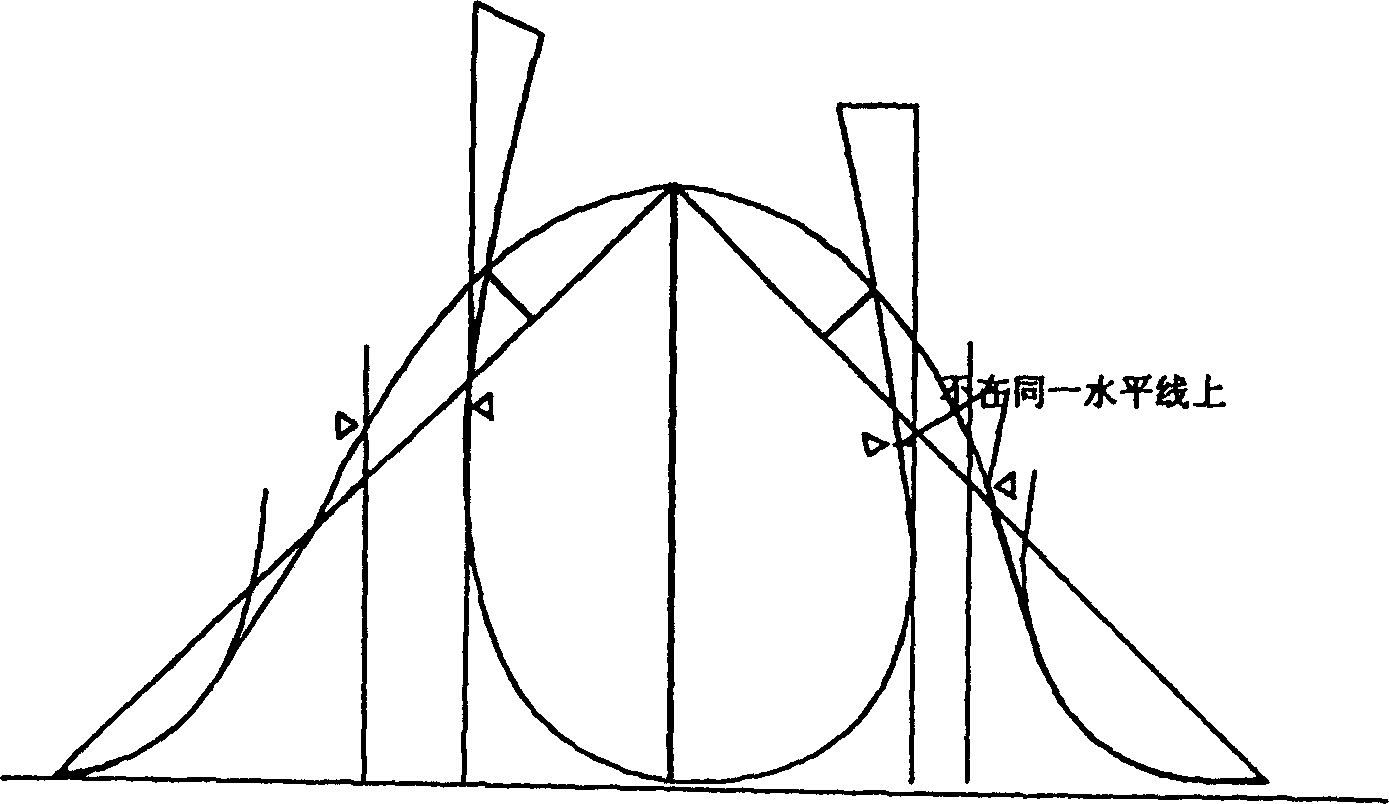

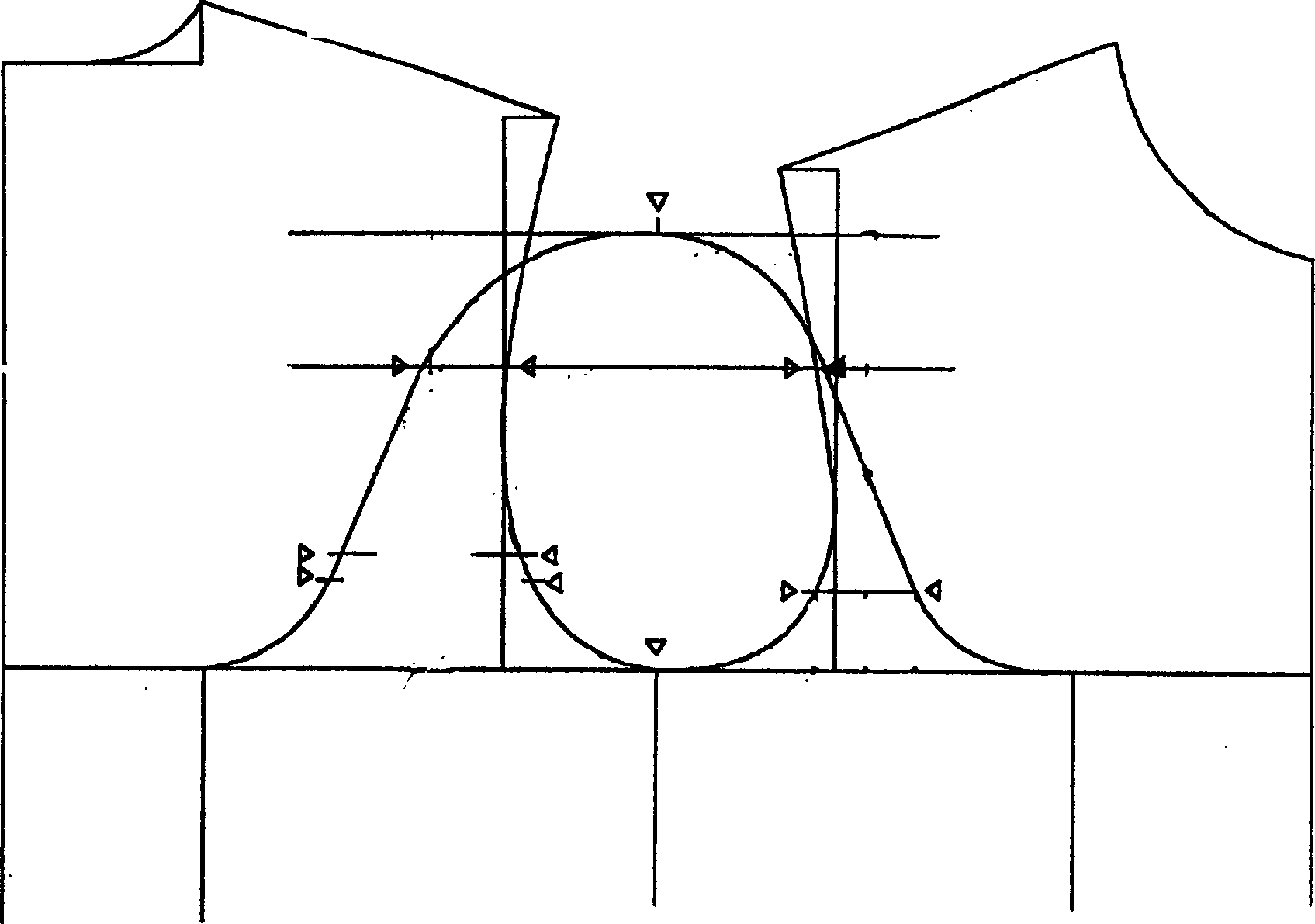

[0032] Embodiment, the clothing material is thin tweed, the shape of the armhole of the clothing body and the position of the knife eye point are as follows: Figure 5 As shown, the arc length of each segment of the armhole is: The sleeve mountain is 17.5cm high. The seam shrinkage corresponding to the arc segment is: d1=0.5cm, d2=0.8cm, d3=0.6cm, d1=1cm. According to Figure 6 and Figure 7 As shown, according to the aforementioned operation steps, the corresponding Figure 5 The armhole arc A'B'C'D'E'F'G' is shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com