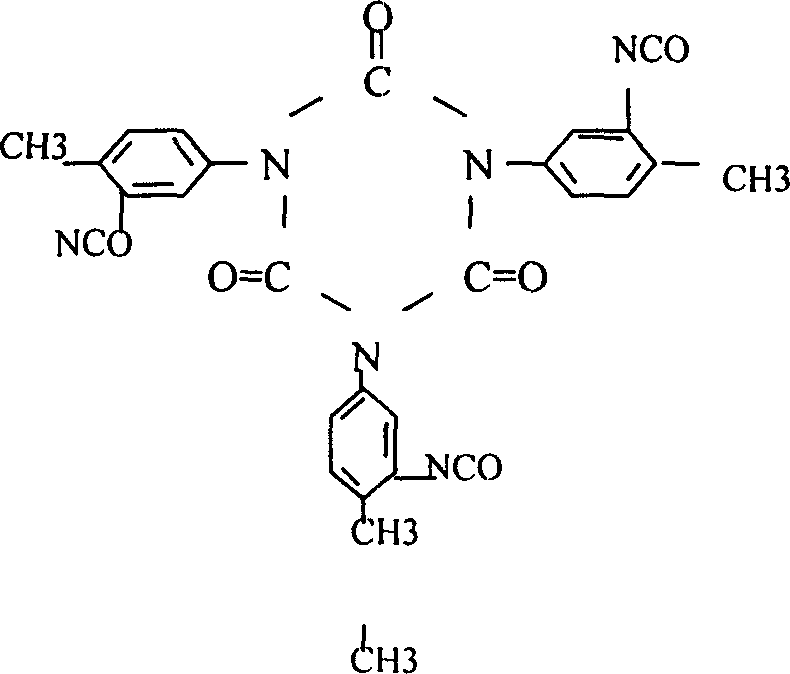

Preparation of dissolvable curing agent for tripolymer of toluene diisocyanate

A technology of trimerization of toluene diisocyanate and isocyanate, which is applied in the direction of coating, can solve the problems of low dilution rate of xylene, limited wide use, poor compatibility, etc., and achieves wide applicability, saving dull powder, and high dilution rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In a tank equipped with a stirrer, thermometer and 2 In a protected 1000ml four-neck flask, add 450g of TDI, 50g of 1-butanol, and 330g of ethyl acetate, stir and heat up, and react at 70°C for 1 hour. After adding 0.080g lithium salicylate and 0.0032g stannous isooctanoate, the reaction starts exothermic, reacts at 90°C, detects the weight percentage of free NCO groups every 1 hour, when the weight percentage of NCO When the solid content was 9.6%, 0.6 g of benzoyl chloride was added immediately, and the temperature was lowered to 40° C. for discharge.

Embodiment 2

[0035] The experimental method is the same as in Example 1. In a tank equipped with a stirrer, thermometer and 2 In a protected 1000ml four-neck flask, add 375g TDI, 29g 2-butanol and 494g butyl acetate, stir and heat up, react at 60°C for 3 hours, then heat up to 80°C, add 0.12g lithium salicylate and 0.004g isooctanoic acid Stannous, react at 80°C, detect the weight percentage of free NCO groups every 1 hour, when the weight percentage of NCO is 7.5%, and its solid content is 50%, add 0.42g chloride immediately Benzoyl, cooled to 40 ℃ discharge.

Embodiment 3

[0037] The experimental method is the same as in Example 1. In a tank equipped with a stirrer, thermometer and 2 In a protected 1000ml four-neck flask, add 515g TBI, 77g n-pentanol, 100g ethyl acetate, 98g butyl acetate, stir and heat up, react at 70°C for 3.5 hours, add 0.076g lithium salicylate and 0.002g stannous isooctanoate , exothermic reaction, heat preservation reaction at 85°C, detect the weight percentage of free NCO groups every 1 hour, when the weight percentage of NCO is 11%, and its solid content is 75%, immediately add 0.52g Benzoyl chloride is cooled to 40°C and discharged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com