Fuse box device

A technology of fuse boxes and fixing devices, which is applied in the direction of emergency protection devices, fuse manufacturing, electrical components, etc., can solve the problems of miniaturization difficulties, achieve the effects of low manufacturing cost, avoid false assembly, and reduce the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

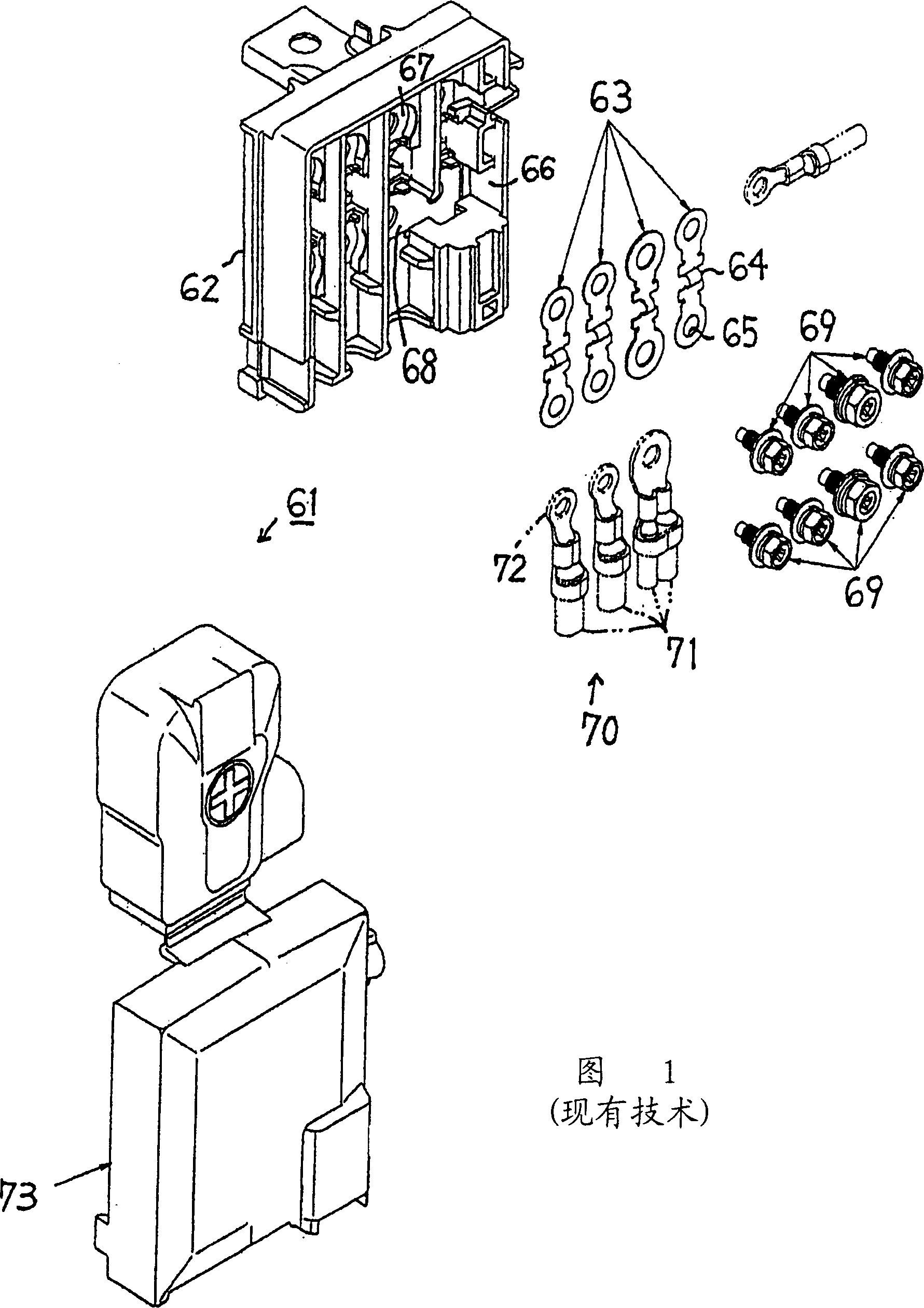

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

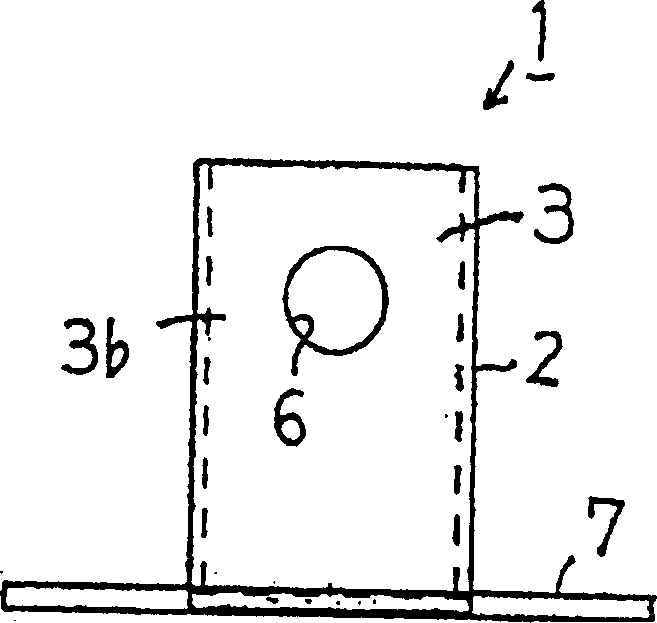

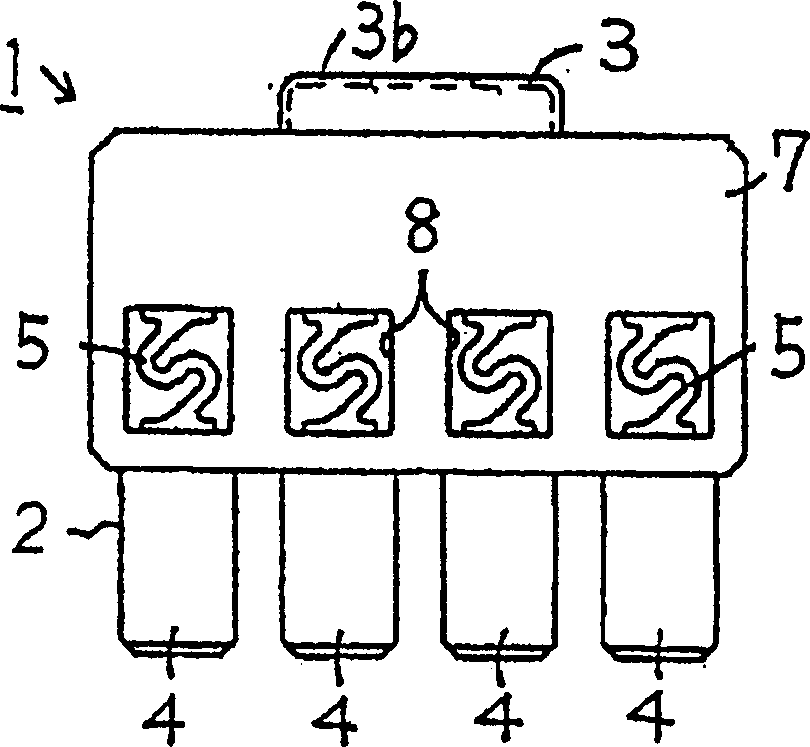

[0026] constitute Figure 2(a) to Figure 2(d) The fuse unit 1 of the shown fuse box device is formed by a conductive sheet, for example a metal sheet. Examples of metals forming the conductive sheet include silver, copper, zinc, tin, lead, and alloys made of one or more of these metals. An input terminal 3 for the battery, an output terminal 4 (male terminal) and a fusible piece portion 5 are integrally formed by the conductive piece. The input terminal 3 is intended to be connected to a power supply terminal of a vehicle battery and comprises a first strip 3a (in normal use arranged vertically) and a second strip 3b (in normal use arranged horizontally). The former is larger than the latter. One end of the second strip 3b (horizontal strip) is connected to the upper end of the first strip 3a (vertical strip). The second strip 3b forms an inverted U-shape when viewed along its cross-sectional view. A substantially circular screw hole 6 for bolt connection is provided at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com