Joint box capable of distinguishing lines and facilitating inspection and maintenance

A technology for checking and repairing joint boxes, applied in the field of joint boxes, which can solve the problems of easy entanglement of wires, inconvenient disassembly and assembly of joint boxes, and inconvenient circuit maintenance, etc., to achieve the effects of convenient installation and fixing, improved flexibility, and easy maintenance and troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

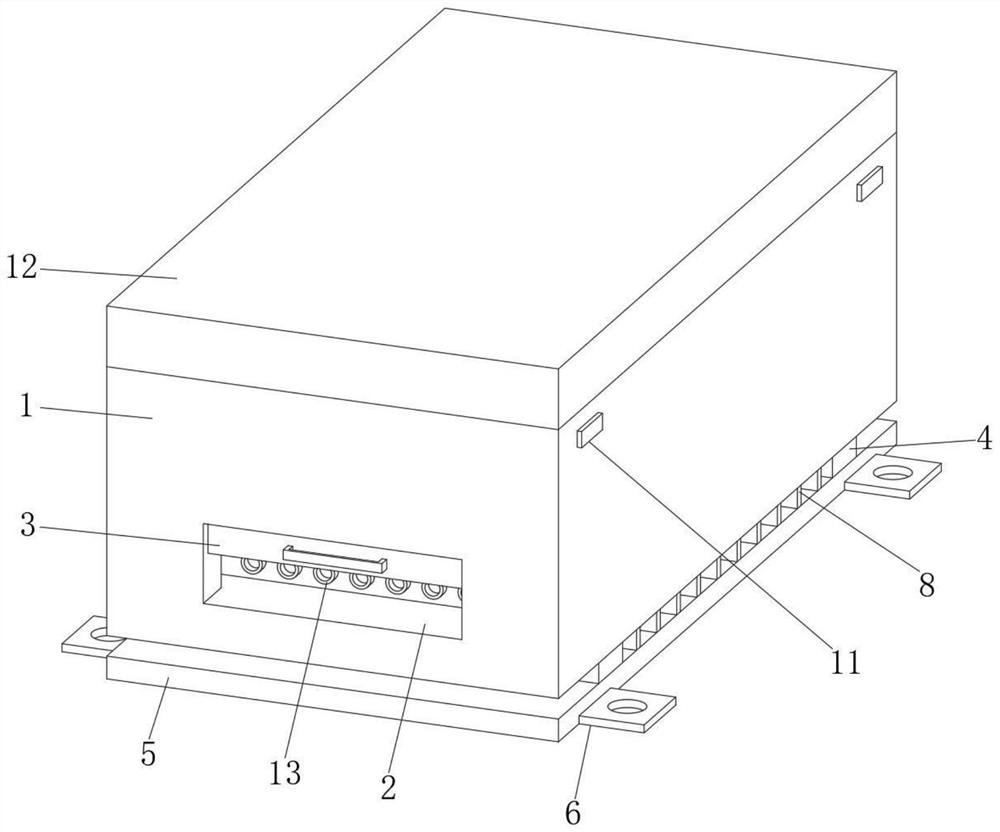

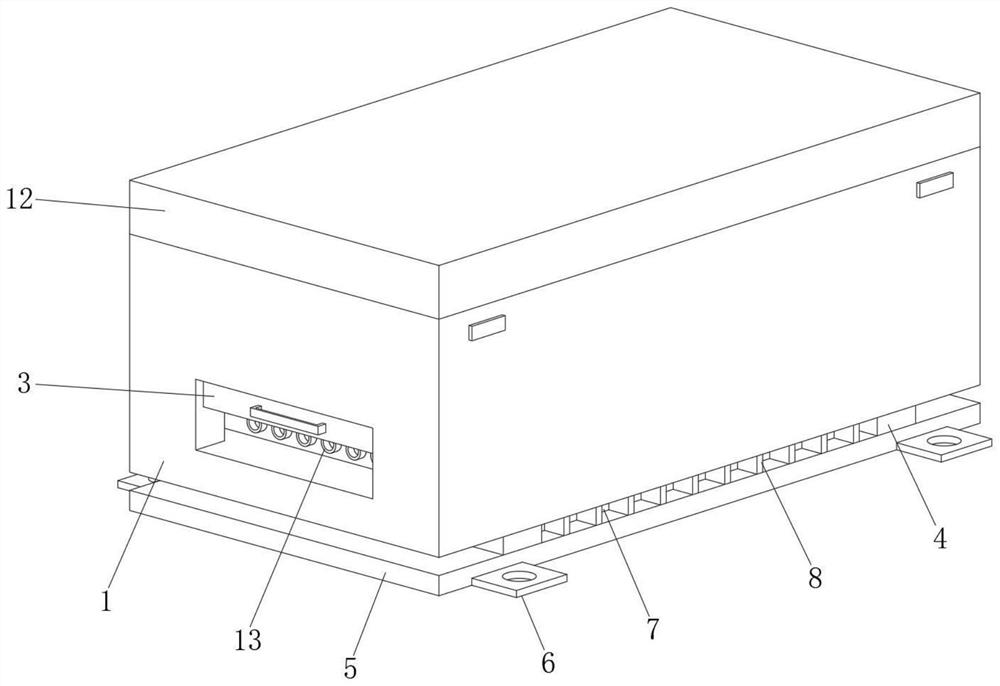

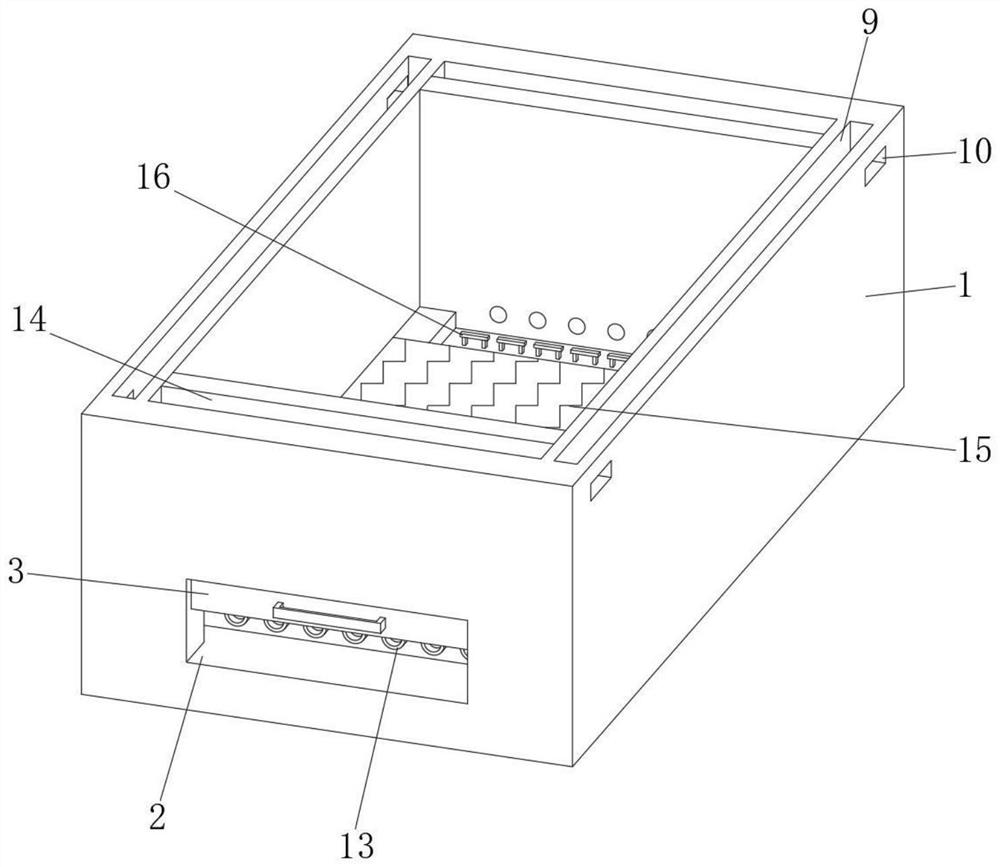

[0029] see Figure 1-6 As shown in the figure, a junction box that can distinguish the lines for easy inspection and maintenance includes an outer casing 1, a fixing block 4 and a horizontal plate 7, the front end surface of the outer casing 1 is provided with a wire opening 2, and the inside of the wire opening 2 is arranged with a baffle 3 , the bottom plate 5 is fixed under the fixed block 4, and the fixed block 4 is located under the casing 1, the interior of the bottom plate 5 is provided with a mounting mechanism 6, the right side of the horizontal plate 7 is installed with a heat dissipation aluminum sheet 8, and the horizontal plate 7 is located in the fixed position The front end of the block 4 and the top surface of the casing 1 are provided with a mounting groove 9, and an opening 10 is provided on the right side of the mounting groove 9. An engaging mechanism 11 is arranged inside the mounting groove 9, and a top is fixed above the engaging mechanism 11. The cover ...

Embodiment 2

[0034] see Figure 4 and Image 6 As shown in the comparison example 1, as an extended embodiment of the present invention, the mounting mechanism 6 includes a mounting plate 601, a mounting hole 602, a connecting plate 603, an adjusting block 604 and an adjusting groove 605, and the mounting plate 601 is provided with mounting holes inside 602 , a connecting plate 603 is connected to the left side of the mounting plate 601 , and an adjusting block 604 is fixed on the left side of the connecting plate 603 , and an adjusting groove 605 is provided on the outside of the adjusting block 604 .

[0035] The mounting plate 601 and the mounting hole 602 are stamped and formed, and the mounting plate 601 forms a telescopic structure with the bottom plate 5 through the cooperation between the connecting plate 603 , the adjusting block 604 and the adjusting groove 605 , and the mounting hole 602 on the mounting plate 601 is connected to the bottom plate 5 . Appropriate fixing parts can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com