Ceramic tile adhesive bonding force testing device

A testing device and bonding force technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as tile damage and difficulty in ensuring measurement accuracy, and achieve the effect of ensuring testing accuracy, avoiding waste of raw materials, and reducing testing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

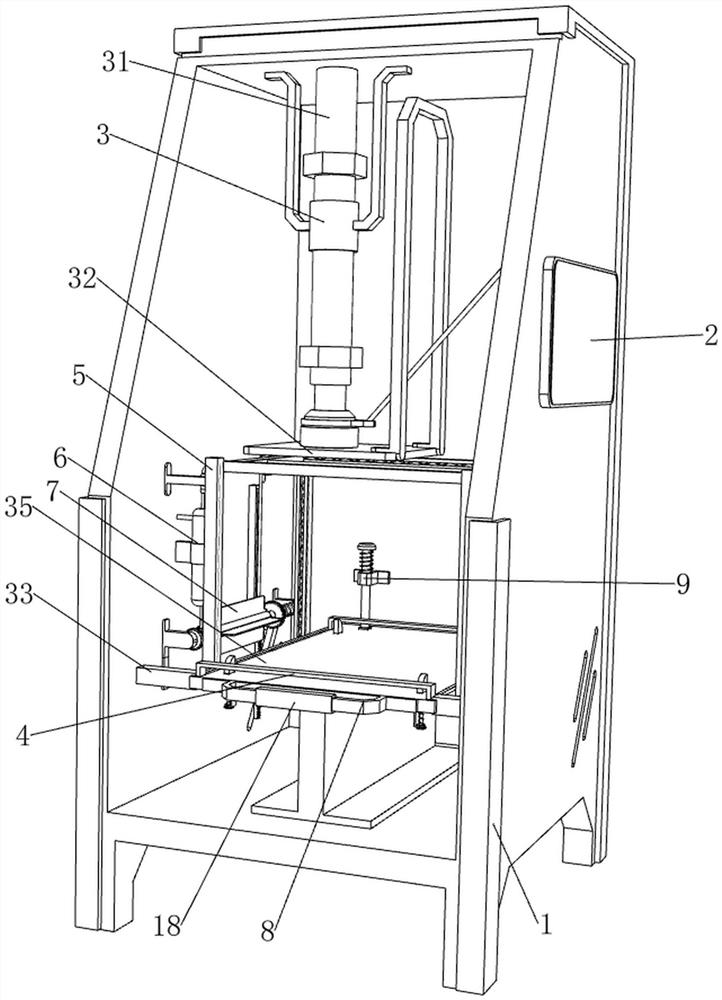

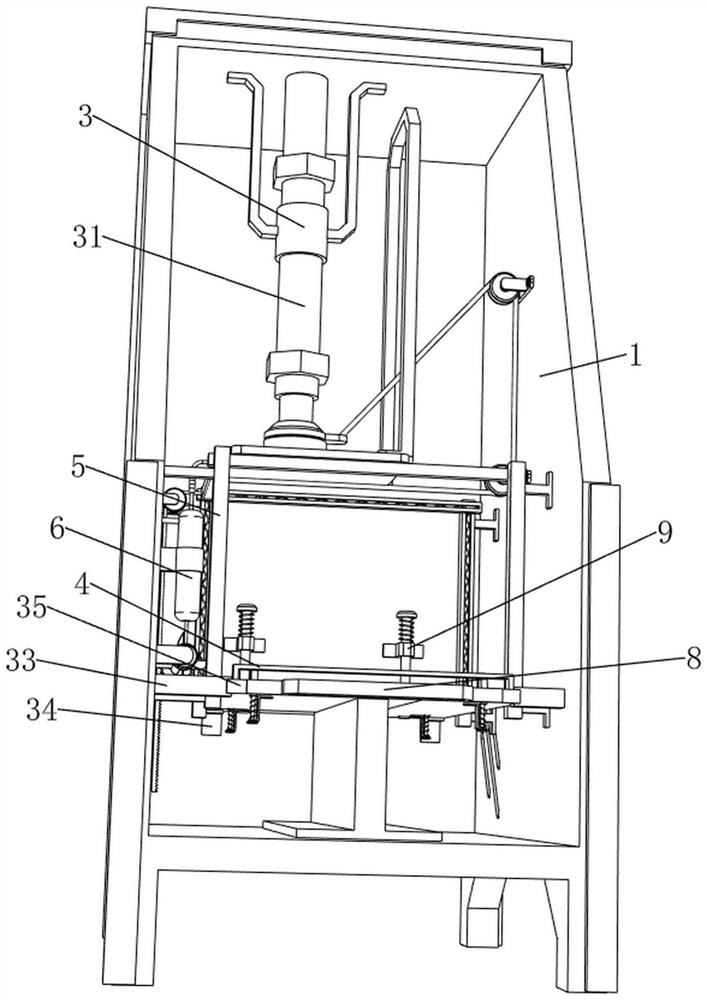

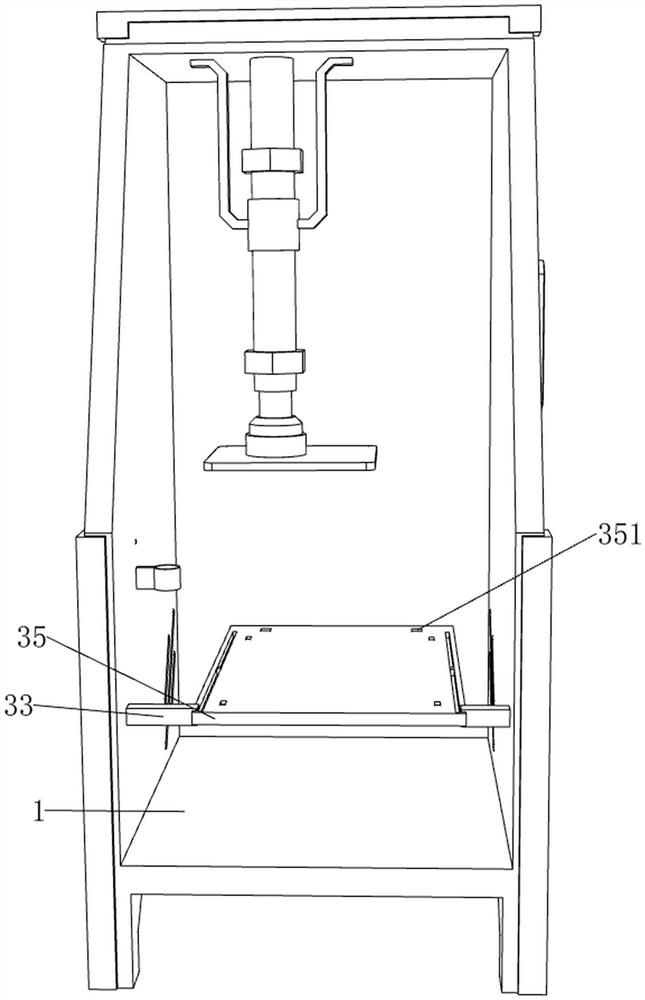

[0037] A tile adhesive bonding force testing device, refer to Figure 1-Figure 3As shown, it includes an outer frame 1, a display screen 2, a first fixing ring 3, a cylinder 31, a drawing plate 32, a support rod 33, a support plate 34, a storage table 35, a limiting mechanism 4 and a coating mechanism 5, the outer frame 1 A display screen 2 is fixed on the upper side of the right part, and the display screen 2 can display the tensile force value. A first fixing ring 3 is fixed on the left front side of the inner top of the outer frame 1; The bottom of the telescopic rod is fixed with a pulling plate 32, the front side of the lower part of the outer frame 1 is fixed with support rods 33 symmetrically left and right, the lower part of the inner rear wall of the outer frame 1 is fixed with a support plate 34 symmetrically left and right, and the support rods 33 are slidably connected. There is an object table 35, and the object table 35 is in contact with the support plate 34. Th...

Embodiment 2

[0042] On the basis of Example 1, refer to figure 1 , Figure 9 and Figure 10 As shown, it also includes an air-drying mechanism 6, which can speed up the drying of glue, and the air-drying mechanism 6 includes a second pulling rope 61, a second guide wheel 62, a toothed rod 63, a gear 64, a rotating shaft 65, a torsion spring 66, a first Four fixed rods 67 , fan blades 671 , third slide rails 68 and fifth springs 69 , a second guide wheel 62 is fixedly connected to the rear side of the lower part of the inner left wall of the outer frame 1 , and a second guide wheel 62 is fixedly connected to the rear side of the lower part of the inner left wall of the outer frame 1 The third slide rail 68 , the third slide rail 68 is located on the lower side of the second guide wheel 62 , the inner and lower side of the third slide rail 68 is slidably provided with a toothed rod 63 , and the toothed rod 63 and the third slide rail 68 are connected with a first Five springs 69, a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com