Micro strain sensor

A sensor and micro-strain technology, applied in the sensor field, can solve the problems of reducing the strain core area, overloading the sensor, easily exceeding the measurement range of the sensor, etc., and achieving the effects of simple mechanical structure, fast response, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

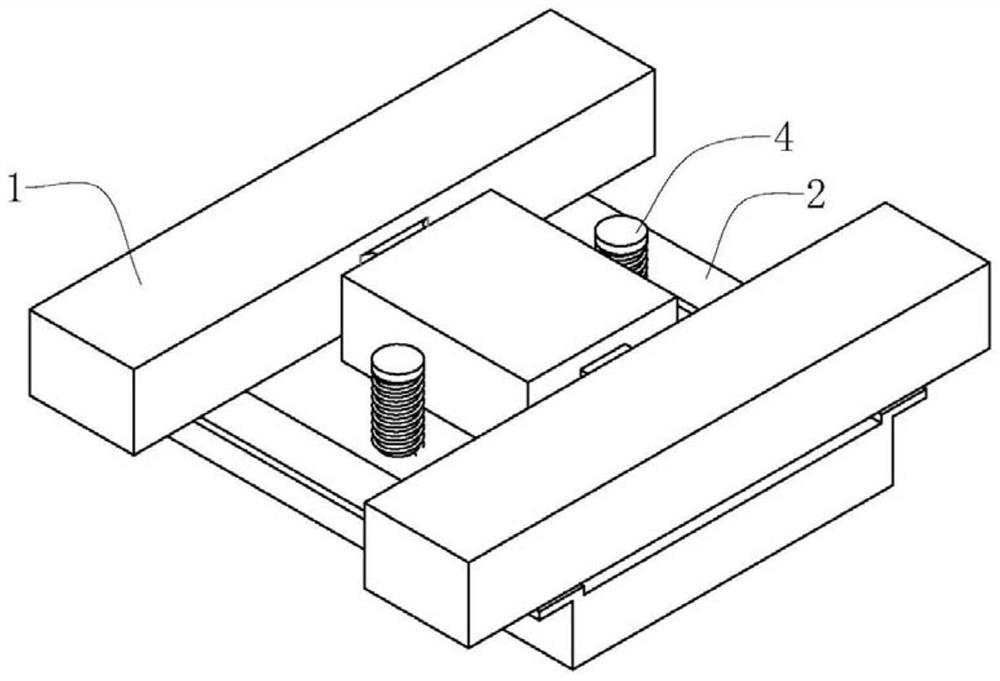

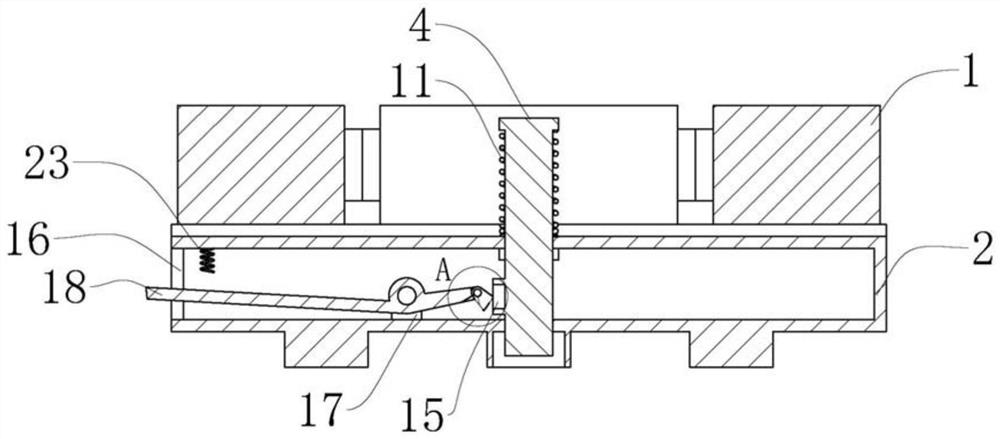

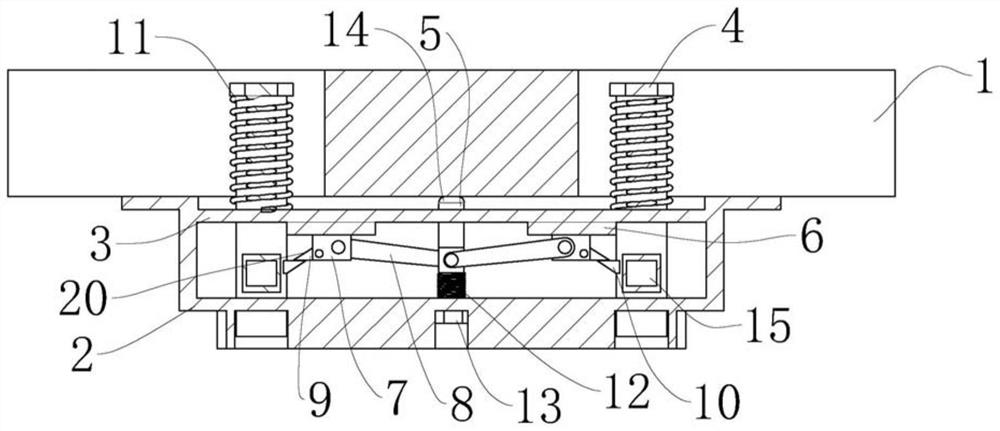

[0021] Example: as Figure 1 to Figure 5 As shown, the present invention provides a micro-strain sensor, including a sensor body 1 and a bracket 2, the bracket 2 is provided with a sensor body 1 and a first transverse plate 3, the sensor body 1 reflects the weight of the object to be measured through deformation, and the bracket 2 Provide support for the sensor body 1. In actual use, the bracket 2 is fixed on a rigid support device preset under the sensor body 1. The two ends of the first horizontal plate 3 are provided with a first connection slidably connected to the first horizontal plate 3. The rod 4 is provided with a second connecting rod 5 slidably connected to the first horizontal plate 3 in the middle, a sliding groove 6 is provided on the side away from the sensor body 1, and the end of the first connecting rod 4 close to the sensor body 1 is sleeved with a second connecting rod 5. A spring 11, the first spring 11 changes the length of the first connecting rod 4 clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com