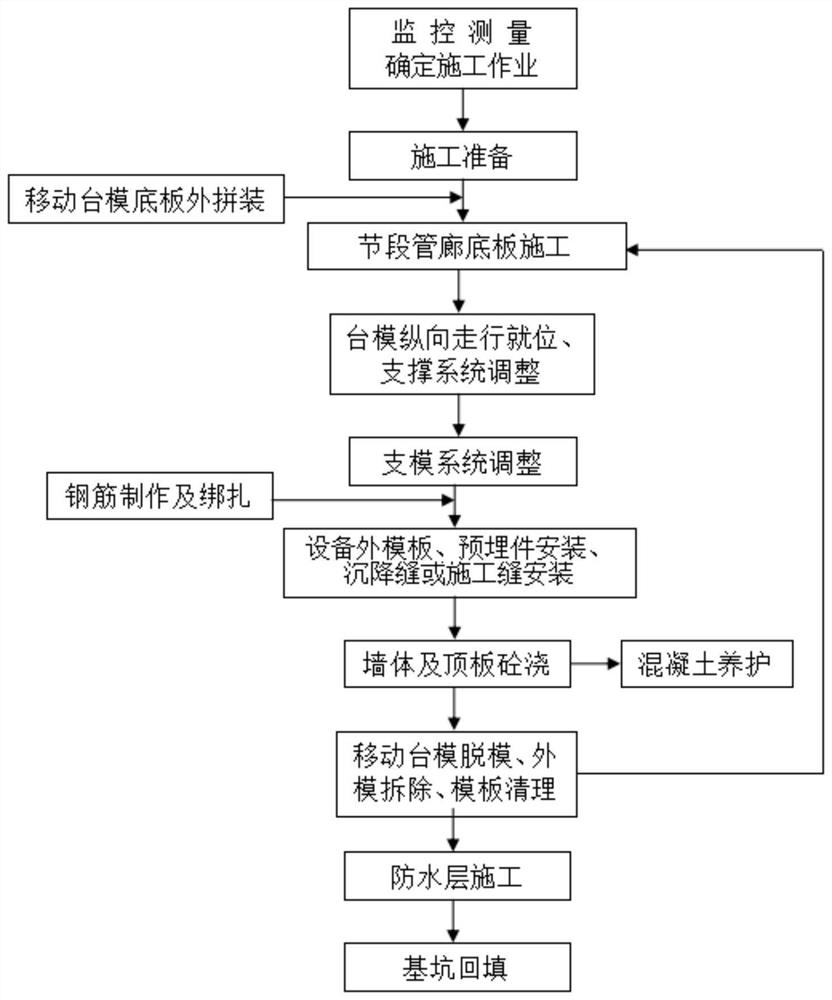

Open-cut cast-in-place underground comprehensive pipe gallery movable bench formwork integrated construction method

A technology of integrated pipe gallery and table formwork, applied in excavation, artificial island, water conservancy projects, etc., can solve the problems of consuming a lot of wood resources, difficult to ensure the appearance quality of the gallery body, not in line with low-carbon green, etc., to save installation and The effect of disassembly time, convenient and fast movement, and small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

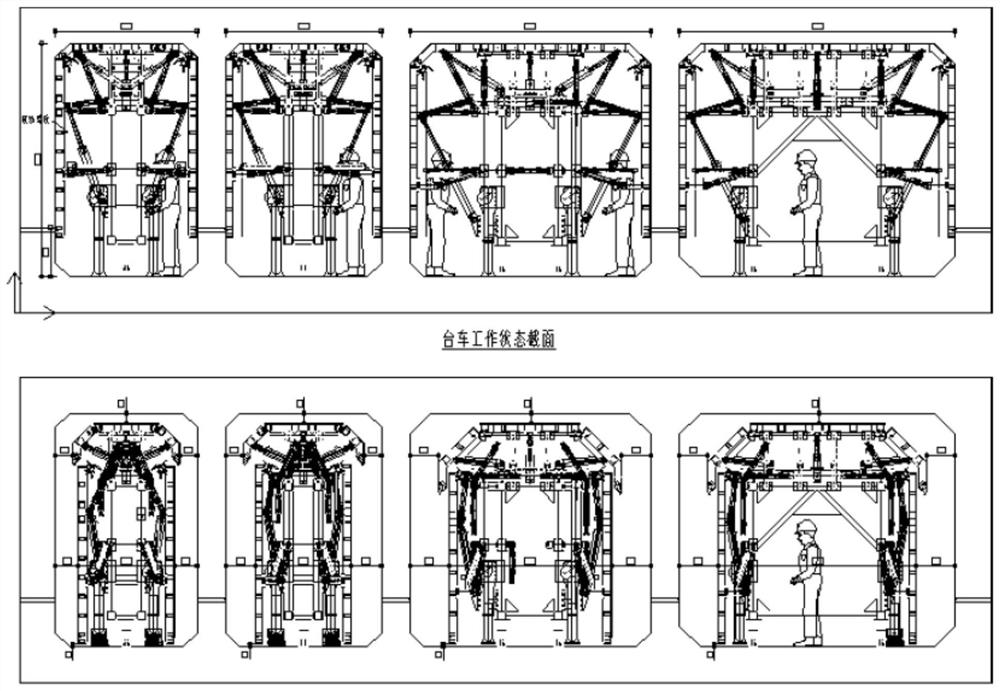

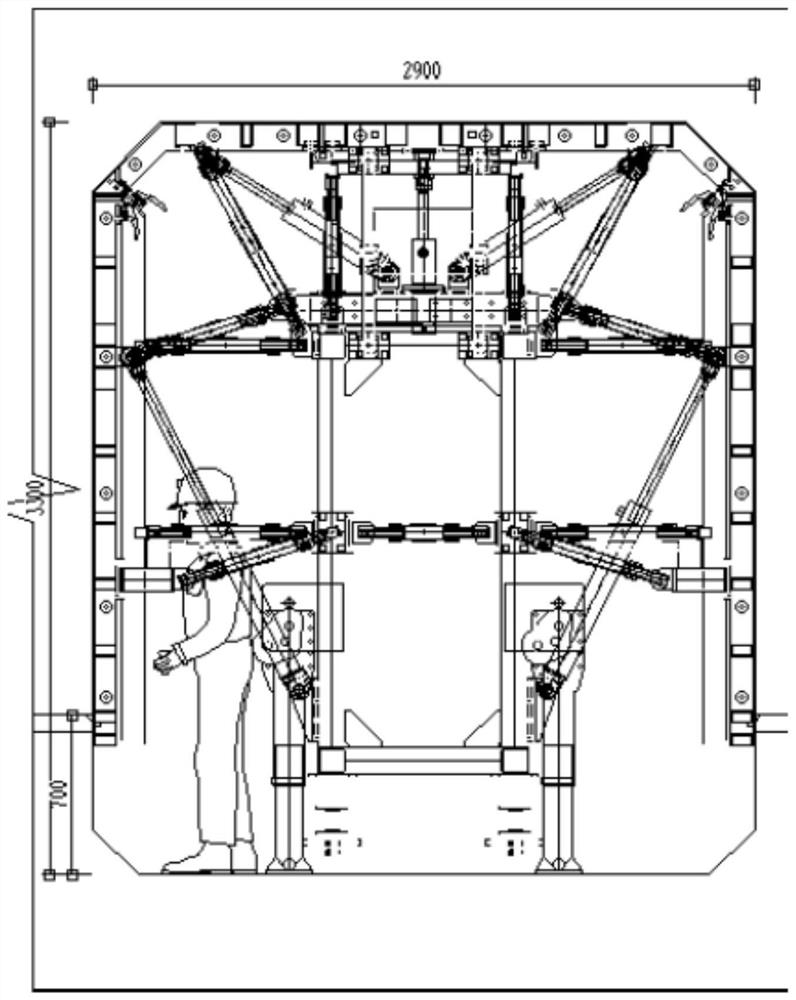

Method used

Image

Examples

Embodiment 1

[0075] Example 1, project overview: The second phase of the integrated pipe gallery project in the start-up area of an international low-carbon city in a city is the construction of a comprehensive pipe gallery and related roads.

[0076] The relocation and restoration project of the pipeline is about 1406.6 meters long and has four pipeline cabins. The pipe gallery is arranged under the lanes, sidewalks and green belts of the existing roads.

[0077] The buried depth of the base of the pipe gallery is about 8.0m. Because the pipe gallery is close to municipal roads and villagers’ buildings, in order to protect the existing roads, existing underground pipelines and existing villagers’ buildings, the comprehensive pipe gallery foundation pit cannot be constructed in the form of large excavation, and must be erected. Support measures. In order to strictly control the deformation of the foundation pit and the fall of groundwater, and try to avoid social influence, the foundati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com