Color sand with high carbon black dispersity and preparation method thereof

A technology of dispersity and carbon black, applied in the field of colored sand with high dispersity of carbon black and its preparation, can solve the problems of easy agglomeration of carbon black, and achieve the effects of improving roughness, improving dispersibility and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

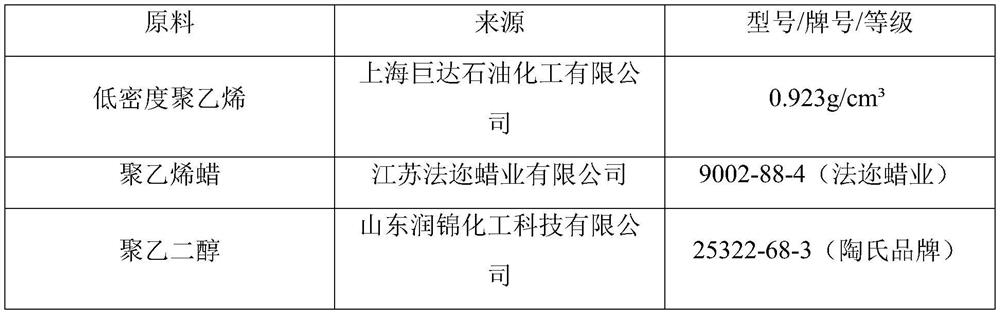

Method used

Image

Examples

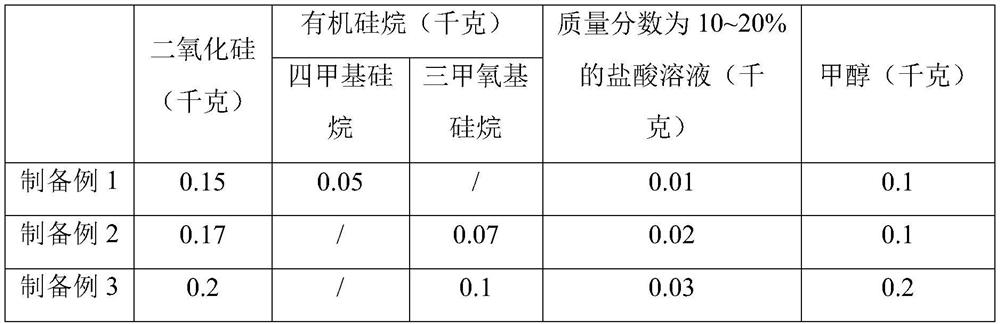

preparation example 1

[0060] A modified silicon dioxide, which is made from the following methods:

[0061] Called 0.15 kg of silicon and 0.1 kg of methanol, placed in the reactor, and heated it while stirring to 60 ℃. The hydrochloric acid solution is 0.01 kg. In 10min, the hydrochloric acid solution with a mass score of 10 % in 10min, reacts 0.5h, filtrates, washed with distilled water, dried until no moisture, and obtained a modified silicon.

[0062] The organic Silicane used in this system is tetramilane.

preparation example 2

[0064] A modified silicon dioxide, which is made from the following methods:

[0065] Called 0.17 kg of silicon dioxide and 0.15 kg of methanol, placed in the reaction kettle, and warmed up while stirring to 70 ℃. The hydrochloric acid solution is 0.02 kg. In 20min, the hydrochloric acid solution with a mass score of 20 % is dripped in 20min. The reaction is 1h, filtering, drying it with distilled water, dried until no water, and the modified silicon dioxide.

[0066] The organic Silicane used in this system is trimethyl oxide.

preparation example 3

[0068] A modified silicon dioxide, which is made from the following methods:

[0069] Called 0.2 kg of silicon and 0.2 kg of methanol, placed in the reactor, and warmed up while stirring to 70 ℃. The hydrochloric acid solution is 0.03 kg. In 20min, the hydrochloric acid solution with a mass score of 20 % is dripped in 20min. The reaction is 1h, filtering, drying it with distilled water, dried until no moisture, and obtaining a modified silicon.

[0070] The organic Silicane used in this system is trimethyl oxide.

[0071] Table 2 is a variety of raw materials and materials in preparation examples 1 to 3

[0072]

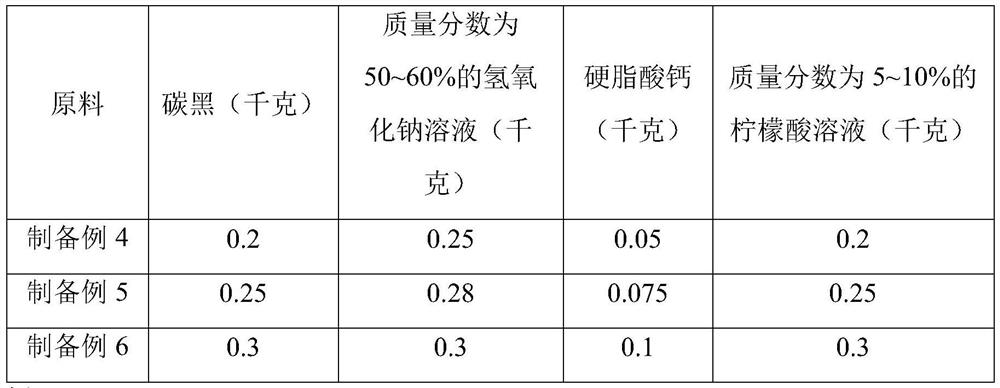

[0073] Modified carbon black preparation example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com