Carriage type automatic pig killing production line

A production line and carriage-type technology, applied in slaughterhouse equipment, slaughtering accessories, electric current slaughtering/stunning, etc., can solve the problems of slow slaughtering efficiency, more labor required, and insufficient craftsmen, so as to improve the driving effect and slaughtering efficiency The effect of high and high slaughtering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

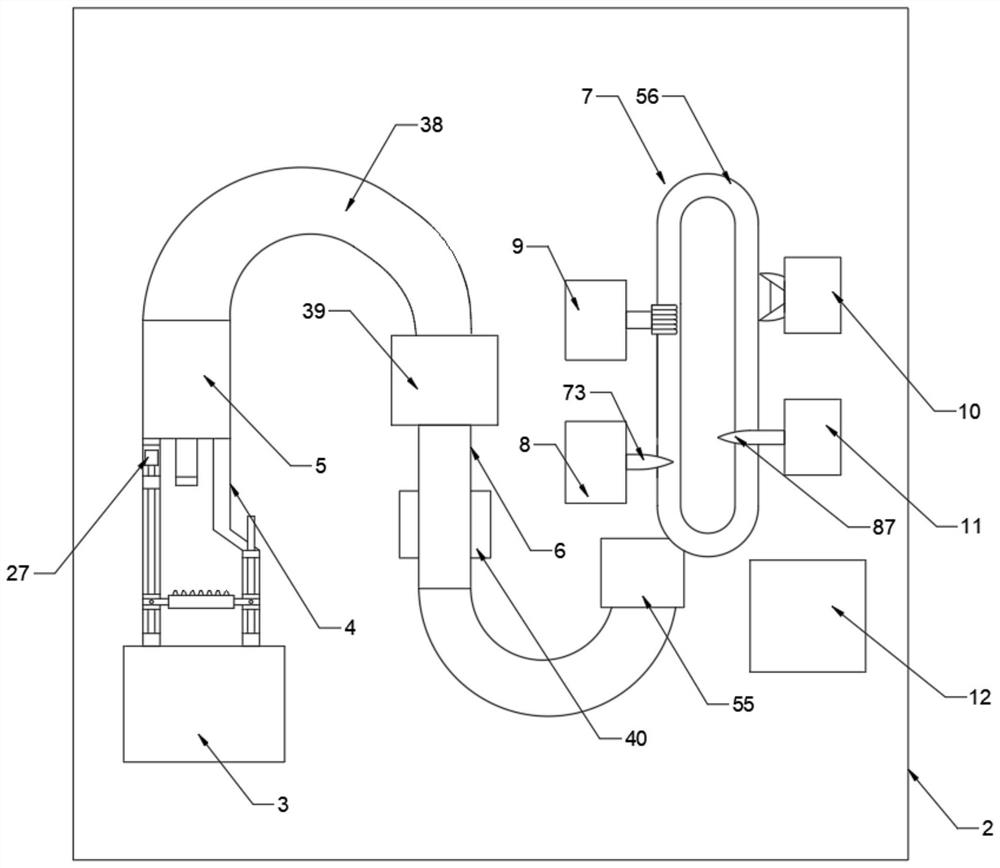

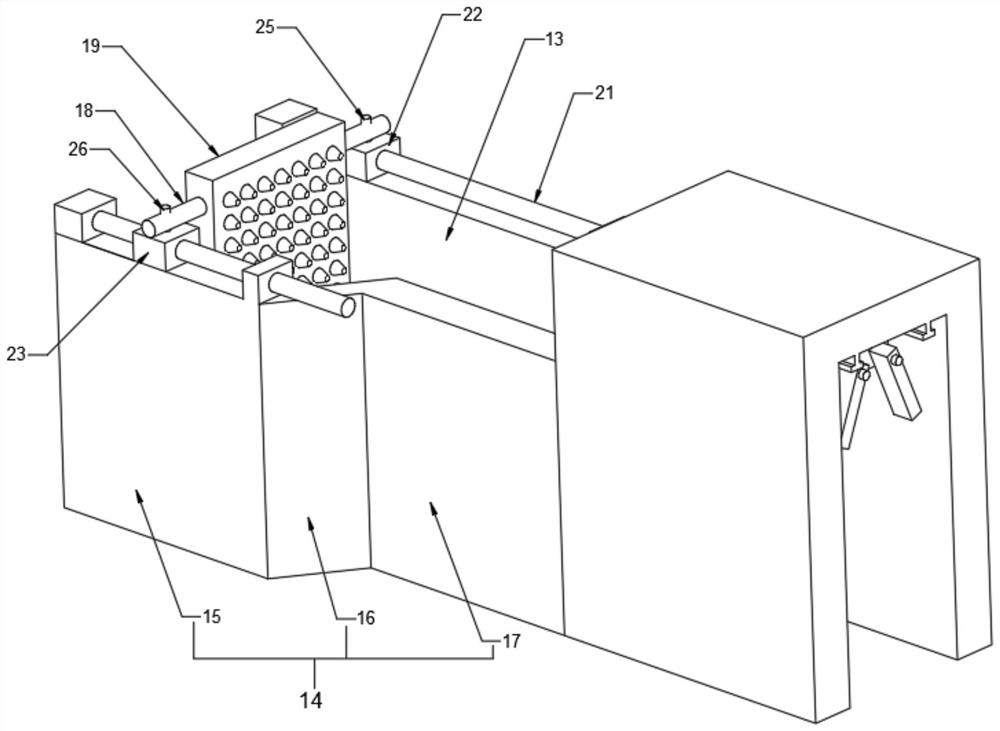

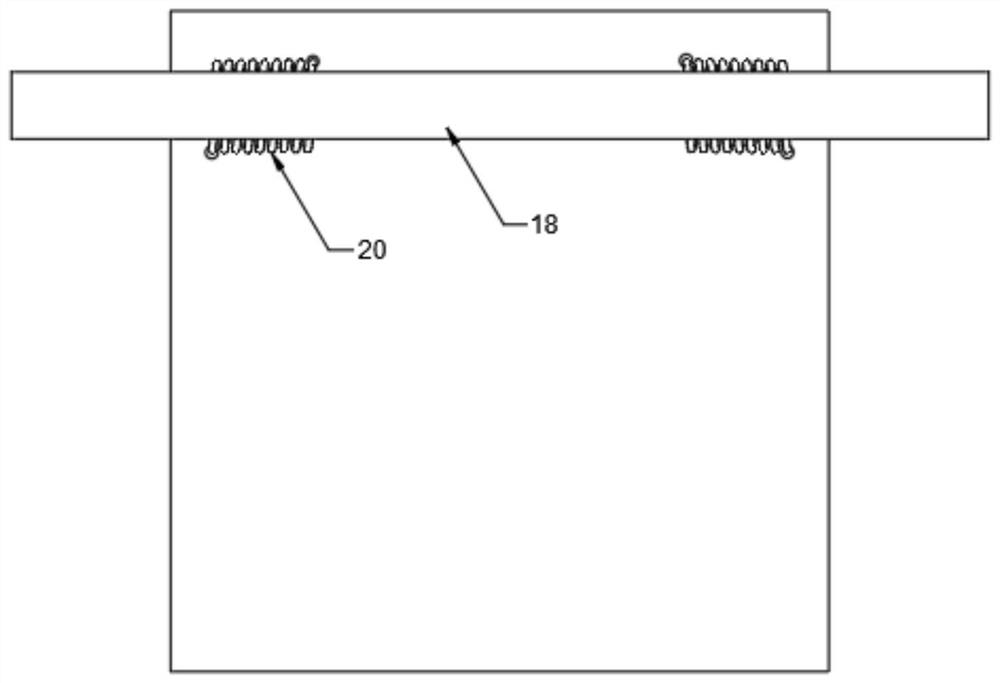

[0034] The technical solutions of the present invention are further described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

[0035] like Figure 1 to Figure 15 As shown, a carriage-type automated pig slaughtering production line includes a transport truck 1, a container 2 is arranged on the transport truck 1, a production line is arranged in the container 2, and the production line includes a pigpen area 3, which is arranged in an "S" shape in turn. The driving mechanism 4, the electric shock killing mechanism 5, the shaving lifting mechanism 6 and the annular conveying mechanism 7, the outer side of the annular conveying mechanism 7 is sequentially provided with a cutting part 8 and a viscera digging part 9 along the conveying direction, and the inner edge of the annular conveying mechanism 7 is arranged along the conveying direction. The head cutting member 10 and the cutting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com