Modeling-following double-function multiplexing thick-wall part optical system and vehicle lamp

An optical system, dual-function technology, applied in the direction of headlights, optical signals, semiconductor devices of light-emitting elements, etc., can solve the problems of optical effect defects, space difficulty of headlights, low precision and flexibility, etc., and achieve uniform lighting effect. , the shape is flexible and the effect of high light output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

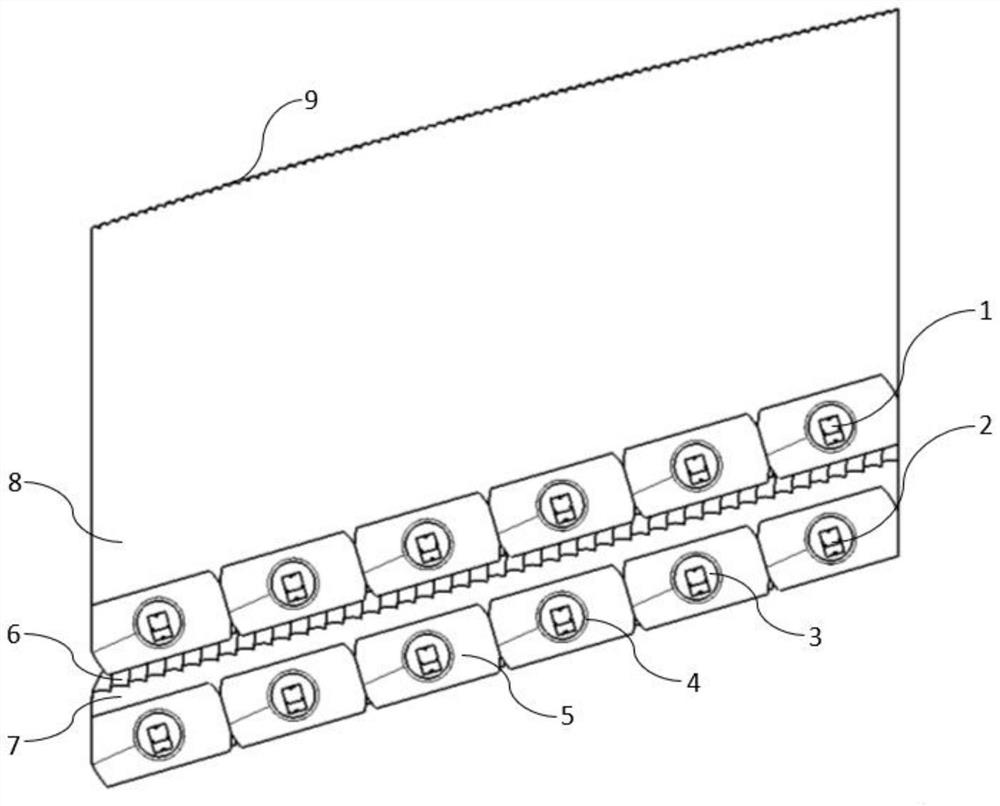

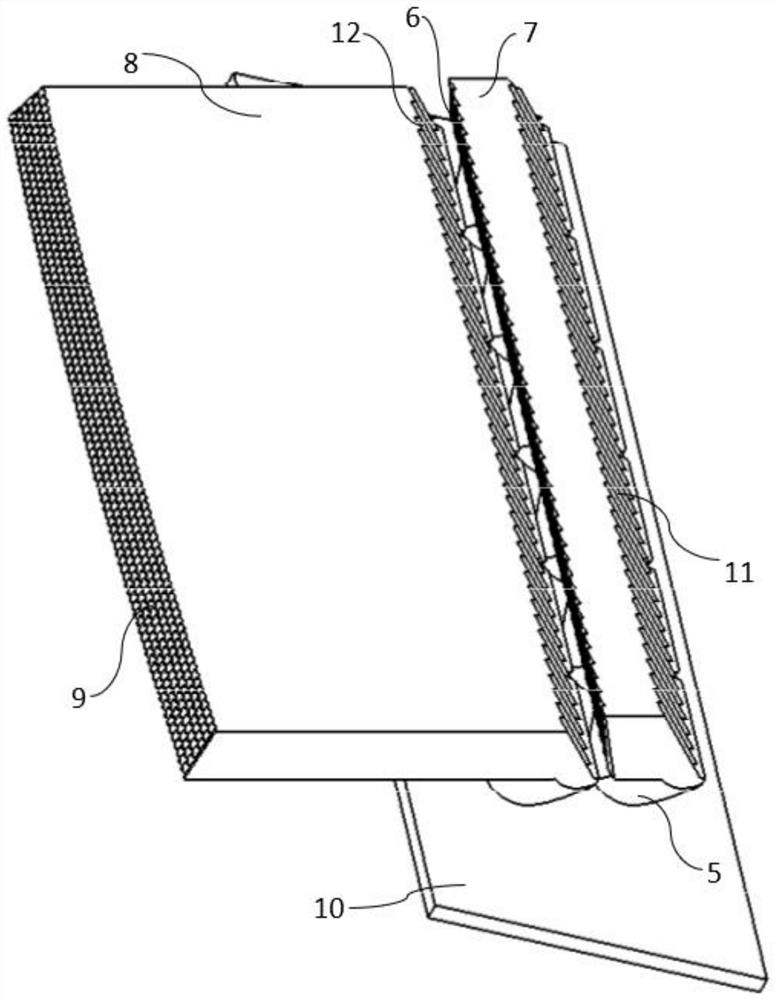

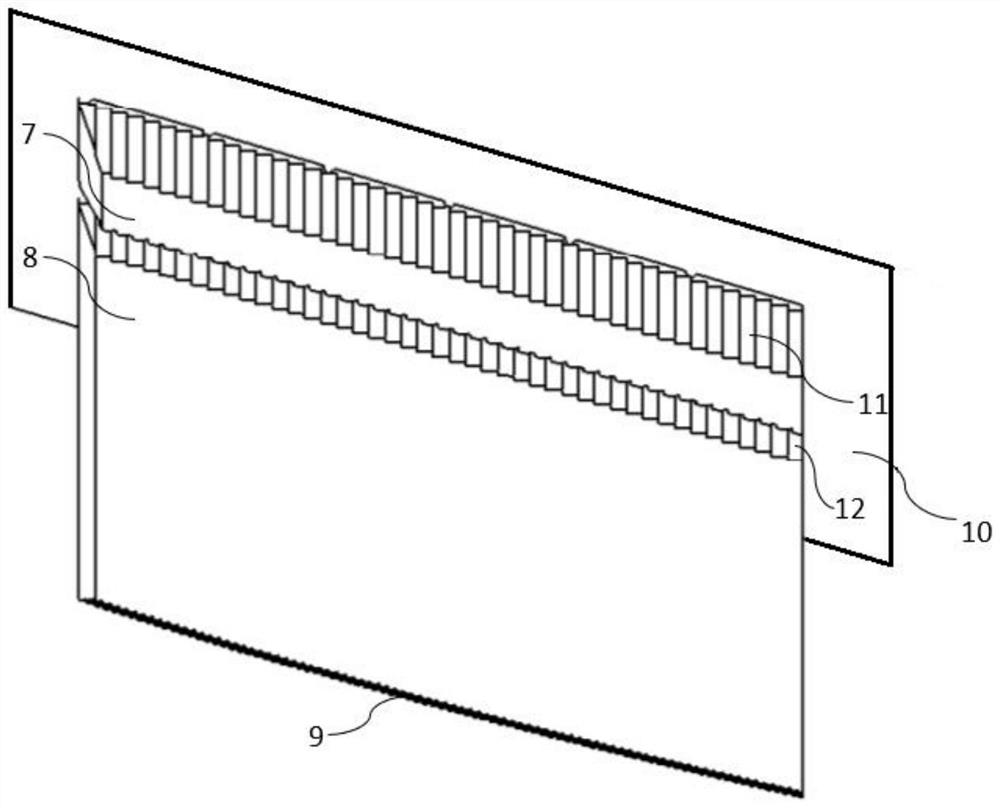

[0051] The present invention provides a dual-function multiplexing thick-walled optical system following modeling, such as Figure 1-13 As mentioned above, it includes a first light source 1 , a second light source 2 , a first thick-walled member 7 , a second thick-walled member 8 , a light entry system and a PCB board 10 . The light emission angle of the first light source 1 and the second light source 2 is 120°. The first light source 1 and the second light source 2 are respectively connected to the PCB board 10. The first light source 1 corresponds to the second thick-walled member 8, and the second light source 2. Corresponding to the first thick-walled member 7, a gap is provided between the first thick-walled member 7 and the second thick-walled member 8. The light entry system is respectively connected to the first thick-walled part 7 and the second thick-walled part 8. The light entry system includes an incident refracting collimating surface 3, an incident refracting ...

Embodiment 2

[0063] The invention also provides a vehicle lamp, which includes a dual-function multiplexed thick-walled optical system following the modeling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com