Light-emitting structure of automobile lamp thin-wall condenser

A light-emitting structure and concentrator technology, which is applied to semiconductor devices, light sources, electric light sources, etc. of light-emitting elements, can solve the problems of low energy utilization rate, high positioning accuracy requirements, and visible appearance of circuit boards, saving vertical space, The effect of high energy utilization and uniform lighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

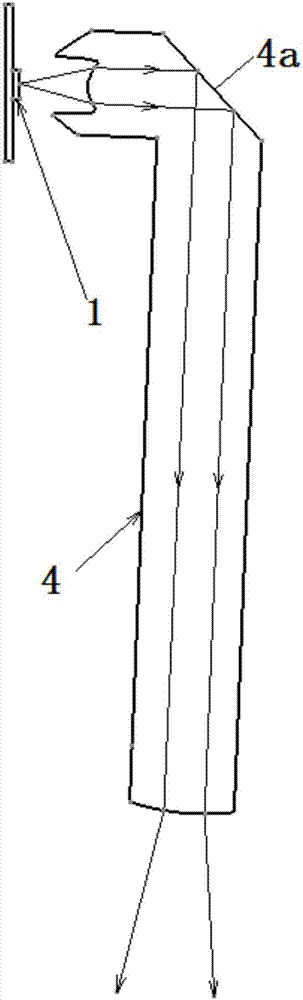

[0024] see image 3 , a light-emitting structure of a car light thick-walled concentrator, including an LED circuit board, LED particles 1, and a corner-type thick-walled concentrator 4; the inner end of the corner-type thick-walled concentrator 4 has a The Fresnel pattern has a total reflection inclined plane at the corner; the outer end surface of the corner type thick-wall concentrator 4 has a pattern that can diffuse light; the LED particles are fixed on the LED circuit board, and are connected with the corner type thick-wall concentrator The position of the inner end of the optical device 4 is corresponding.

[0025] In this example, see image 3 , the corner type thick-wall concentrator 4 is L-shaped.

[0026] In this example, see image 3 , the direction of the parallel light rays reflected by the inclined total reflection plane is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com