Adjustable combined peristaltic pump

A peristaltic pump and adjustable technology, applied in the field of peristaltic pumps, can solve the problems of inconvenient adjustment of the outlet pressure, shortened service life of the hose, inconvenient control, etc., and achieve the effects of easy operation, extended service life, and convenient and precise adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

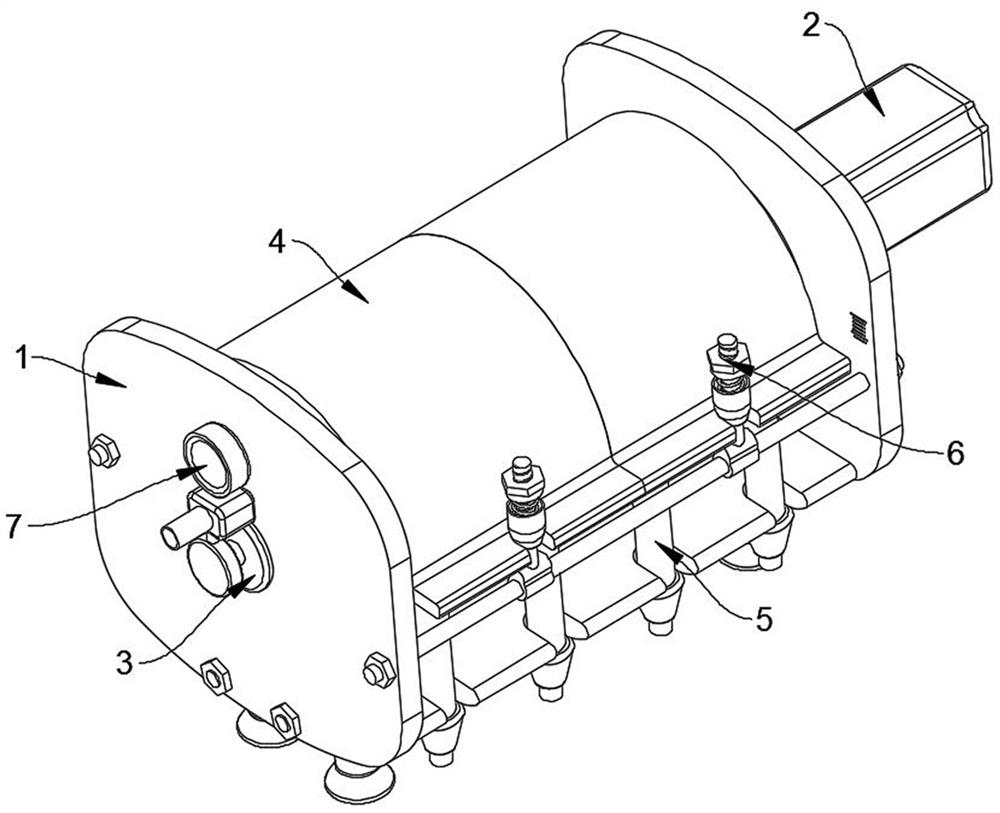

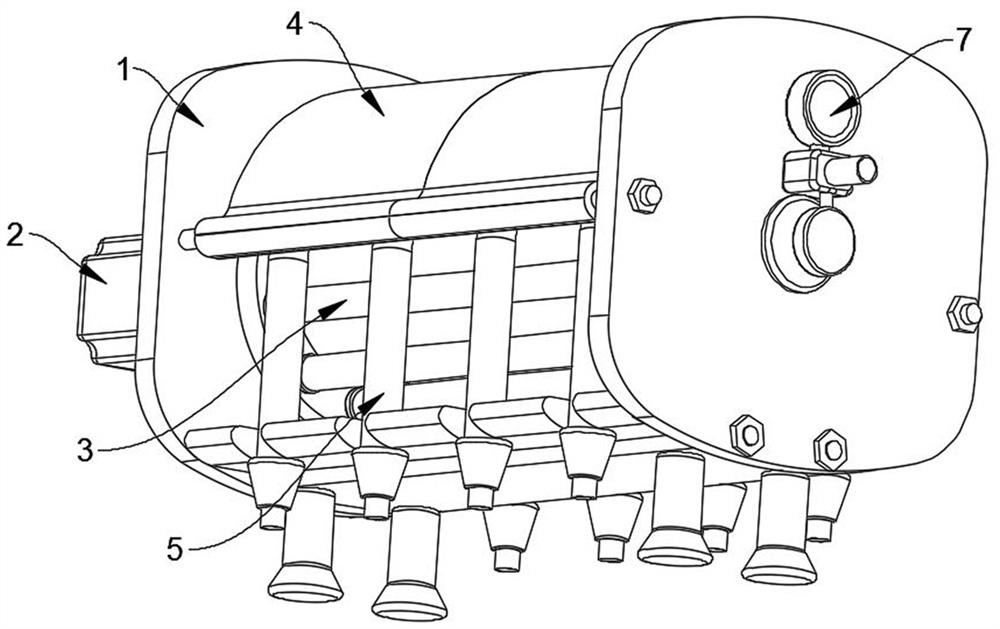

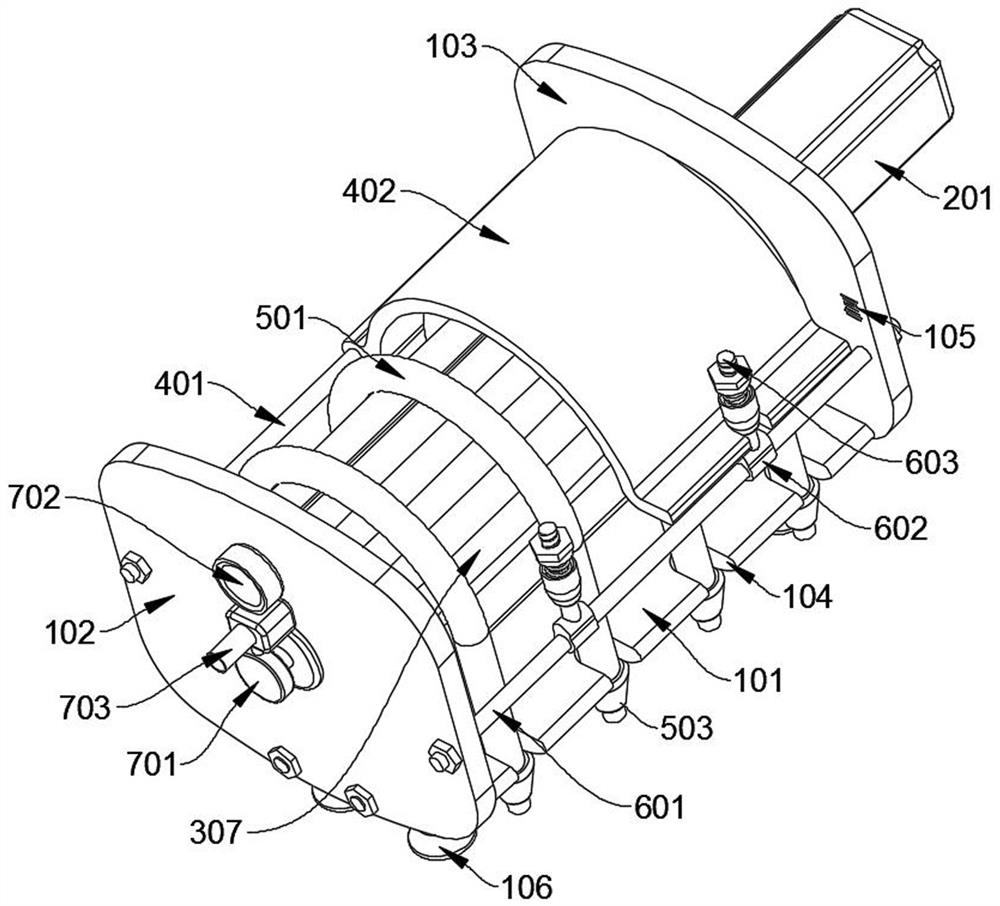

[0029] see Figure 1-9 As shown, an adjustable combined peristaltic pump includes a frame assembly 1, a drive assembly 2 is fixedly installed on one side of the frame assembly 1, and a pump head roller assembly 3 is fixedly installed inside the frame assembly 1, and the output of the drive assembly 2 The end is plugged into the pump head roller assembly 3, and the drive assembly 2 drives the pump head roller assembly 3. Between the interior of the frame assembly 1 and above the pump head roller assembly 3, a pressing and holding assembly 4 is rotatably installed. , the middle position of the frame assembly 1 is evenly plugged with four hose assemblies 5, and the hose assemblies 5 bypass the pump head roller assembly 3, and the middle position of the hose assembly 5 is located between the pump head roller assembly 3 and the pressure Between the holding components 4 and the other side between the frame components 1, an adjusting component 6 is fixedly installed, and the upper en...

Embodiment 2

[0036] see Figure 1-10 As shown, an adjustable combined peristaltic pump includes a frame assembly 1, a drive assembly 2 is fixedly installed on one side of the frame assembly 1, and a pump head roller assembly 3 is fixedly installed inside the frame assembly 1, and the output of the drive assembly 2 The end is plugged into the pump head roller assembly 3, and the drive assembly 2 drives the pump head roller assembly 3. Between the interior of the frame assembly 1 and above the pump head roller assembly 3, a pressing and holding assembly 4 is rotatably installed. , the middle position of the frame assembly 1 is evenly plugged with four hose assemblies 5, and the hose assemblies 5 bypass the pump head roller assembly 3, and the middle position of the hose assembly 5 is located between the pump head roller assembly 3 and the pressure Between the holding components 4 and the other side between the frame components 1, an adjusting component 6 is fixedly installed, and the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com