Impurity recovery device in food paperboard papermaking process

A recycling device and paper card technology, applied in the field of papermaking, can solve problems such as inability to treat waste residues, and achieve the effects of improving practicability and automation, improving recycling rate, and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

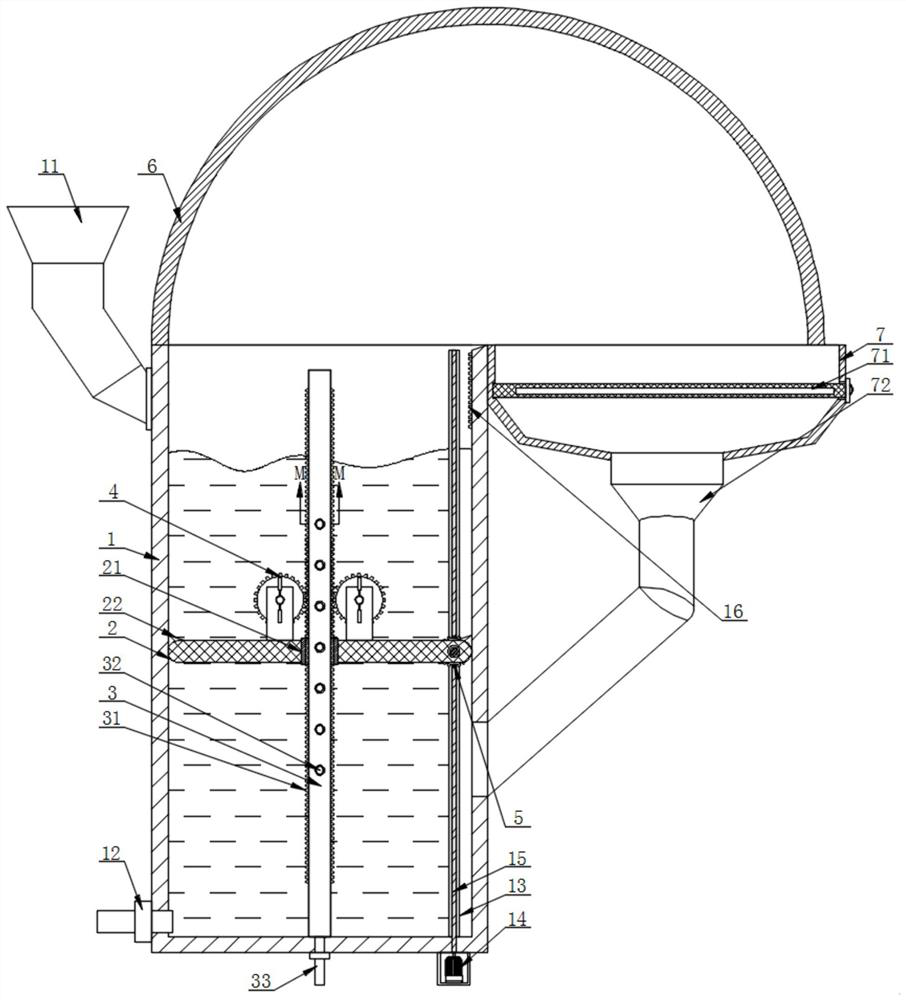

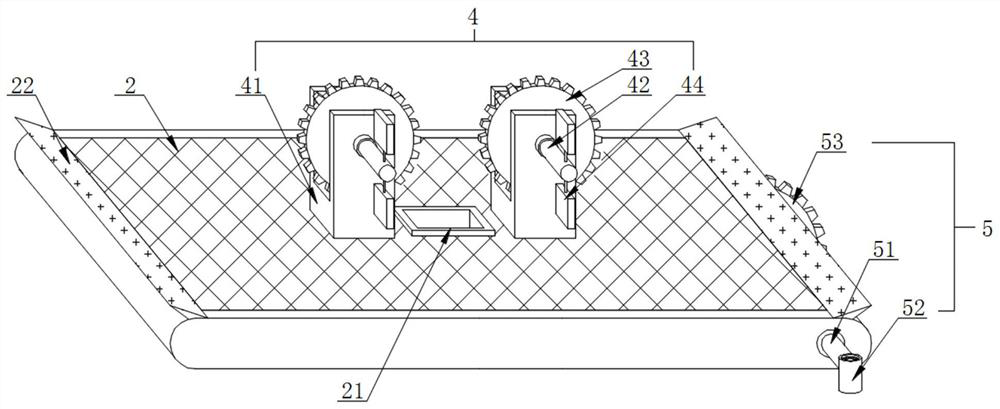

[0035] Refer to the manual attached Figure 1-5 , an impurity recovery device in the process of making food cardboard, including a recovery box 1, a feeding hopper 11 is installed through the top of one side of the recovery box 1, a filter screen 2 is arranged inside the recovery box 1, and the A drain pipe 12 (with a control valve inside) is installed through the bottom of one side of the recovery box 1, a positioning groove 13 is opened on both inner walls of the recovery box 1, and the top and bottom of the positioning groove 13 are movable between the top and bottom of the groove A screw rod 15 is embedded, one side of the filter screen 2 is provided with a turning mechanism 5, and the turning mechanism 5 is correspondingly arranged with the screw rod 15, and the bottom of the inner cavity of the recovery box 1 is fixedly embedded with a fixed column 3 , the filter screen 2 is sleeved on the rod wall of the fixed column 3 , and the top of the filter screen 2 is provided wi...

Embodiment 2

[0041] Refer to the manual attached Figure 1-5 , an impurity recovery device in the process of making food cardboard, including a recovery box 1, a feeding hopper 11 is installed through the top of one side of the recovery box 1, a filter screen 2 is arranged inside the recovery box 1, and the A drain pipe 12 is installed through the bottom of one side of the recovery box 1, a positioning groove 13 is opened on both inner walls of the recovery box 1, and a screw rod 15 is movably embedded between the top and bottom of the positioning groove 13, One side of the filter screen 2 is provided with a turning mechanism 5, and the turning mechanism 5 is correspondingly arranged with the screw rod 15. The bottom of the inner cavity of the recovery box 1 is fixedly embedded with a fixed column 3, and the filter screen 2 is set. On the rod wall of the fixed column 3 , two stirring mechanisms 4 symmetrically arranged with respect to the fixed column 3 are arranged on the top of the filte...

Embodiment 3

[0048] Refer to the manual attached Figure 1-5 , an impurity recovery device in the process of making food cardboard, including a recovery box 1, a feeding hopper 11 is installed through the top of one side of the recovery box 1, a filter screen 2 is arranged inside the recovery box 1, and the A drain pipe 12 is installed through the bottom of one side of the recovery box 1, a positioning groove 13 is opened on both inner walls of the recovery box 1, and a screw rod 15 is movably embedded between the top and bottom of the positioning groove 13, One side of the filter screen 2 is provided with a turning mechanism 5, and the turning mechanism 5 is correspondingly arranged with the screw rod 15. The bottom of the inner cavity of the recovery box 1 is fixedly embedded with a fixed column 3, and the filter screen 2 is set. On the rod wall of the fixed column 3 , two stirring mechanisms 4 symmetrically arranged with respect to the fixed column 3 are arranged on the top of the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com