Multi-stage adjustable nanofiltration system and application of salt separation process

An adjustable, nanofiltration technology, applied in water/sewage multi-stage treatment, general water supply conservation, chemical instruments and methods, etc., can solve problems such as low efficiency, achieve scientific and reasonable design, high-efficiency nanofiltration separation, and optimize process parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

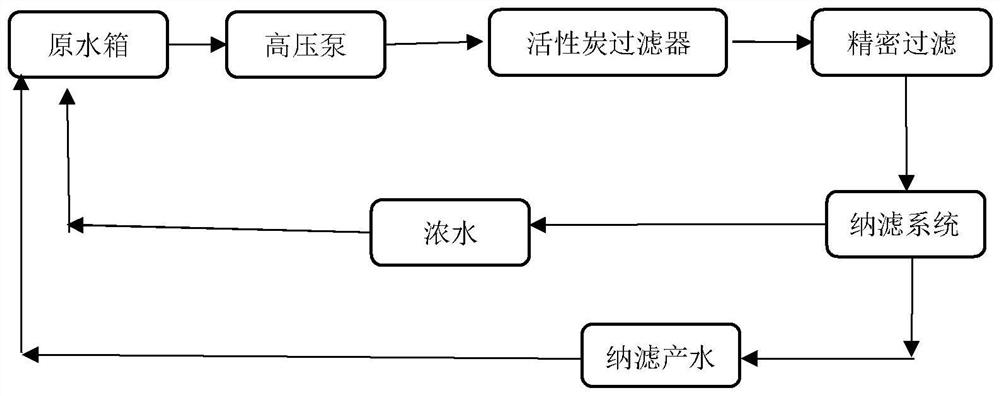

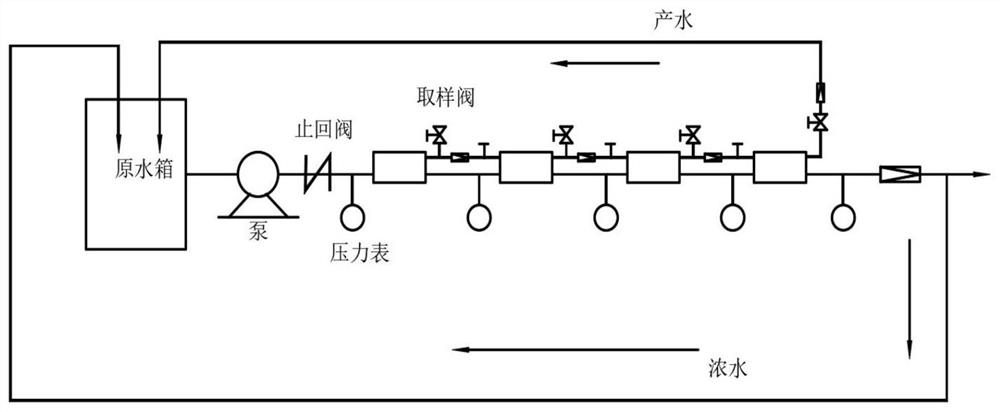

[0019] A multi-stage adjustable nanofiltration system, such as figure 1 As shown, including raw water tank, high-pressure pump, activated carbon filter, precision filter, nanofiltration components, the above devices are connected in series in sequence, as shown in figure 2 As shown, the nanofiltration assembly includes at least four membrane elements connected in series, and the produced water and concentrated water of the previous membrane element both enter the next membrane element, and finally flow out from the end of the system respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com