Double-layer shoe sole manufacturing mold and using method thereof

A mold, double-layer technology, applied in the field of shoe molds, can solve problems such as complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following embodiments are given and described in detail in conjunction with the accompanying drawings.

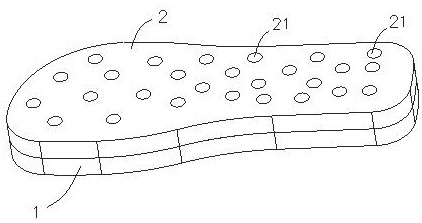

[0029] like figure 1 As shown, this embodiment provides a double-layered sole, including a first-layer sole 1 and a second-layer sole 2, the first-layer sole 1 is located under the second-layer sole 2 and is fixedly connected, the first-layer sole 1 and the second-layer sole 2 are The two-layer sole 2 is formed with a plurality of through holes 21 up and down. The through holes 21 of the first layer of sole 1 and the through holes 21 of the second layer of sole 2 correspond up and down. Specifically, the first layer of sole 1 and the second layer of sole 2 The material is ETPU foam material.

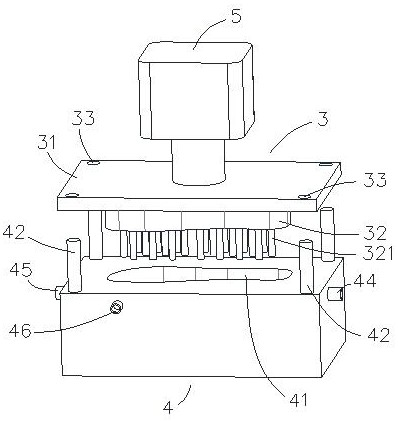

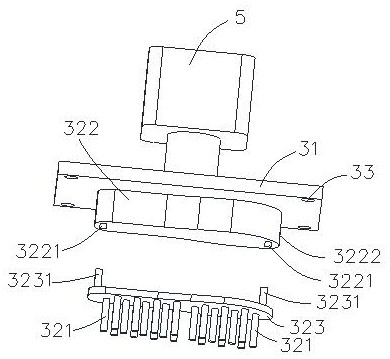

[0030] like Figure 2-5 As shown, a double-layer shoe sole is produced by using a double-layer shoe sole manufacturing mold, and the mold includes an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com