Online cleaning device and online cleaning method for liquid level meter of vacuum pump separation tank

A technology for cleaning devices and liquid level gauges, which is applied to cleaning methods and tools, measuring devices, and lubrication indicating devices, etc. It can solve problems such as unstable operation of vacuum pumps, increased workload, and damage to the pump body, so as to avoid production efficiency and product failure. quality, prevention of metering distortion, and simple cleaning steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

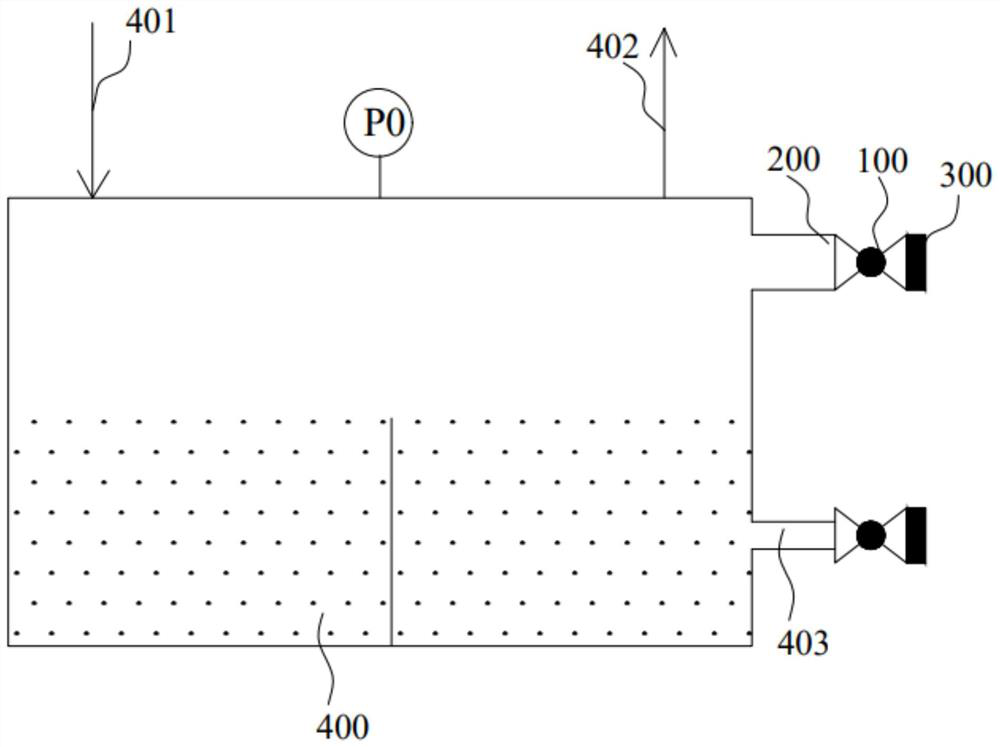

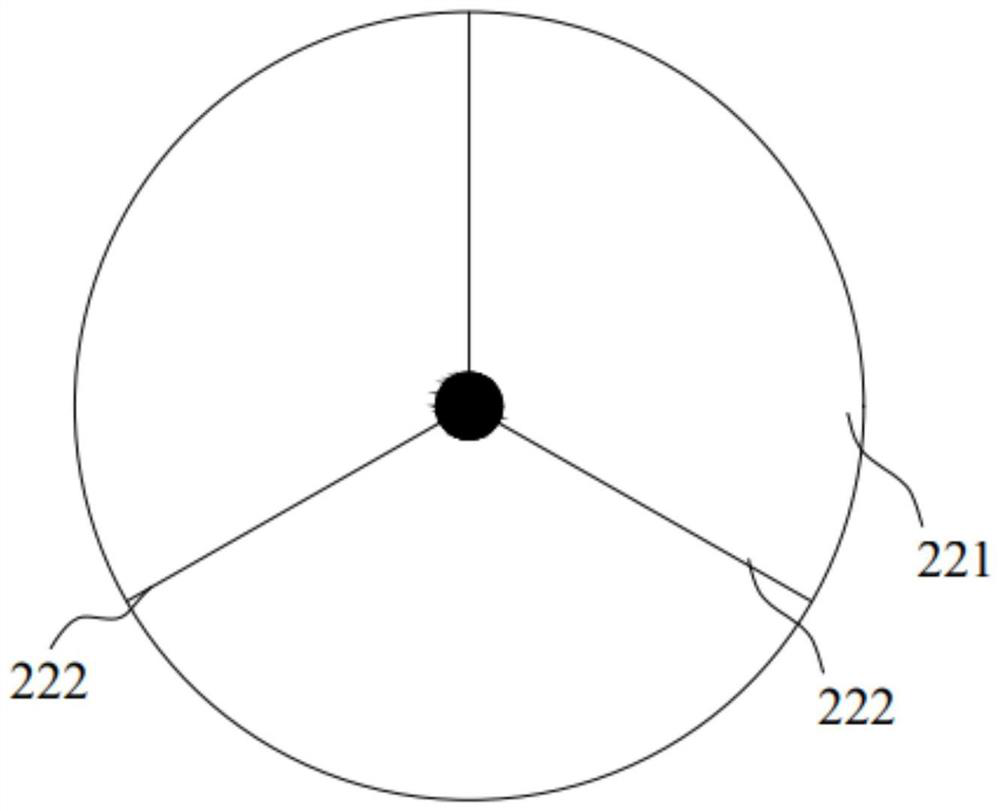

[0045] like figure 1As shown, the separation tank 400 has an acid gas inlet 401 and an acid gas outlet 402, the acid gas introduced by the vacuum pump enters the separation tank 400 through the acid gas inlet 401, and the separation tank 400 separates the acid gas from gas and liquid, and the acid gas after the separation The gas is discharged from the acid gas outlet 402 of the separation tank 400, and the separated vacuum condensate remains in the separation tank 400. A part of the vacuum condensate in the separation tank 400 will be discharged from the sewage pipe 403 at the bottom of the separation tank 400, Part of the working fluid of the vacuum pump is circulated into the pump body of the vacuum pump. The liquid level gauge 300 is used to measure the capacity of the vacuum condensate in the separation tank 400, and is connected to the separation tank 400 through the lead pipe 200. Since the impurities in the acid gas will gradually accumulate in the lead pipe 200, the l...

Embodiment 2

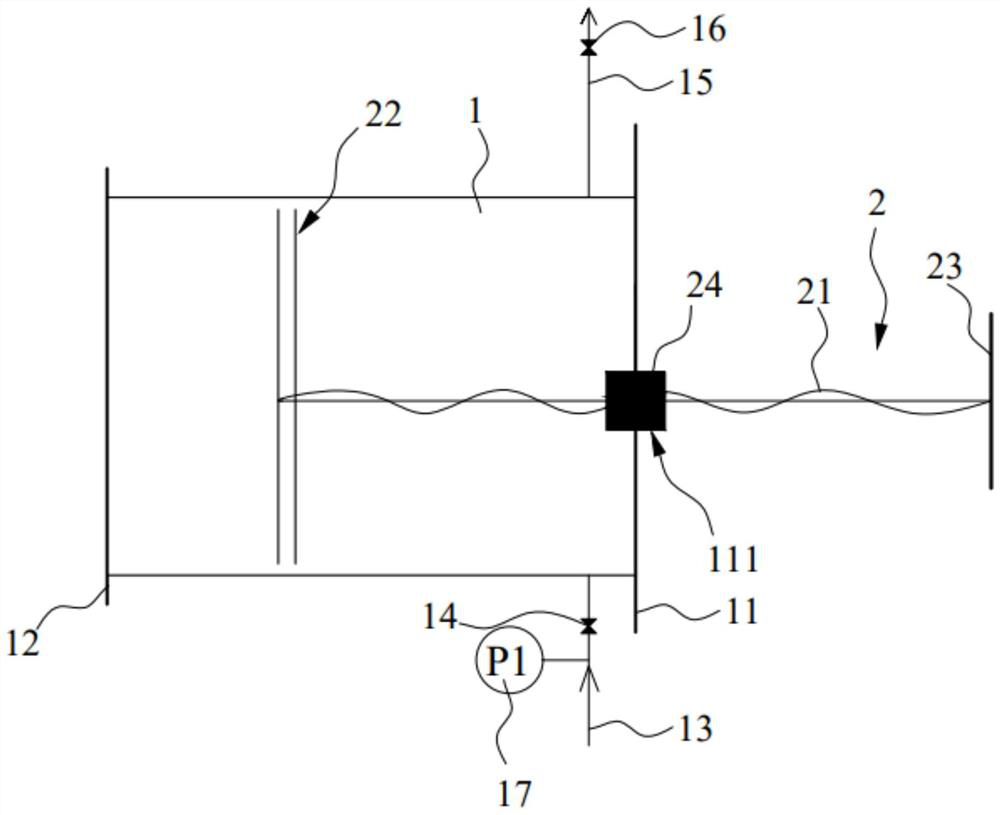

[0056] The second embodiment of the present invention provides an online cleaning method, such as Figure 4 As shown, using the vacuum pump separation tank liquid level gauge online cleaning device in the first embodiment, including the following steps:

[0057] Step S1, remove the liquid level gauge 300 of the separation tank 400, connect the connector 12 of the cleaning cartridge 1 to the lead pipe valve 100 of the liquid level gauge 300, and close the lead pipe valve 100;

[0058] Step S2, open the water inlet pipe 13 through the first control valve 14 of the cleaning cylinder 1, and the cleaning water enters the cleaning cylinder 1;

[0059] Step S3, slowly open the lead pipe valve 100, adjust the first control valve 14, so that the water pressure of the water inlet pipe 13 is not less than 0.1Mpa, until the lead pipe valve 100 is fully opened; The tube 1 enters the guide tube 200 so as to have a scouring effect;

[0060] Step S4, make the rotating rod 21 rotate, the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com