Aqueous resin emulsion

A technology of water-based resin and emulsion, applied in the direction of coating, etc., can solve the problems of not easy to disperse the emulsion, insufficient mechanical stability of the emulsion, etc., and achieve the effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

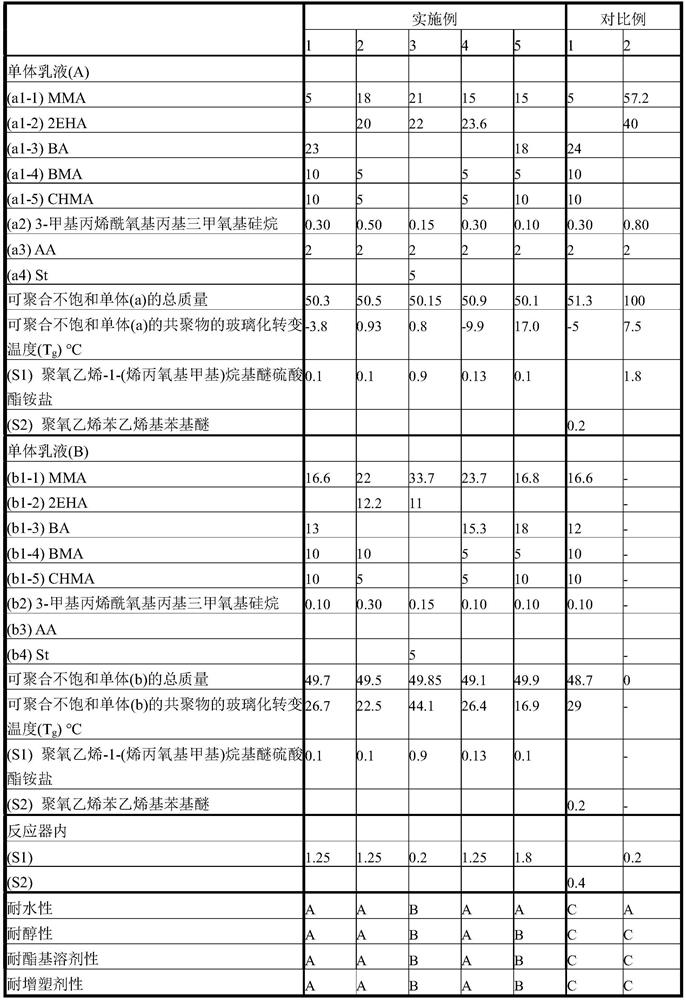

Examples

Embodiment 1

[0158] A monomer emulsion is prepared from various polymerizable unsaturated monomers, then a pre-emulsion is prepared from the monomer emulsion, and an aqueous resin emulsion is synthesized from the pre-emulsion. The specific process is as follows.

[0159] (Preparation of Monomer Emulsion (A))

[0160] As shown in Table 1, 5 parts by mass of (a1-1) MMA, 23 parts by mass of (a1-3) BA, 10 parts by mass of (a1-4) BMA, and 10 parts by mass of (a1-5) CHMA, 2 parts by mass of (a3) AA and 0.3 parts by mass of (a2) 3-methacryloyloxypropyltrimethoxysilane were mixed uniformly to prepare a polymerizable unsaturated monomer (a) solution (50.3 mass parts) share).

[0161] To a solution prepared by uniformly mixing 14 parts by mass of water and 0.1 part by mass of (S1) polyoxyethylene-1-(allyloxymethyl)alkyl ether sulfate ammonium salt, the above-mentioned polymerizable non-polymer was added. The monomer (a) solution is saturated, and then the mixed solution is stirred by a stirrer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com