General plan value curve management method

A management method and planning curve technology, applied in the direction of AC network voltage adjustment, electrical components, single network parallel feeding arrangement, etc., can solve problems such as inflexible configuration, inconvenient use, and huge difference in management functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

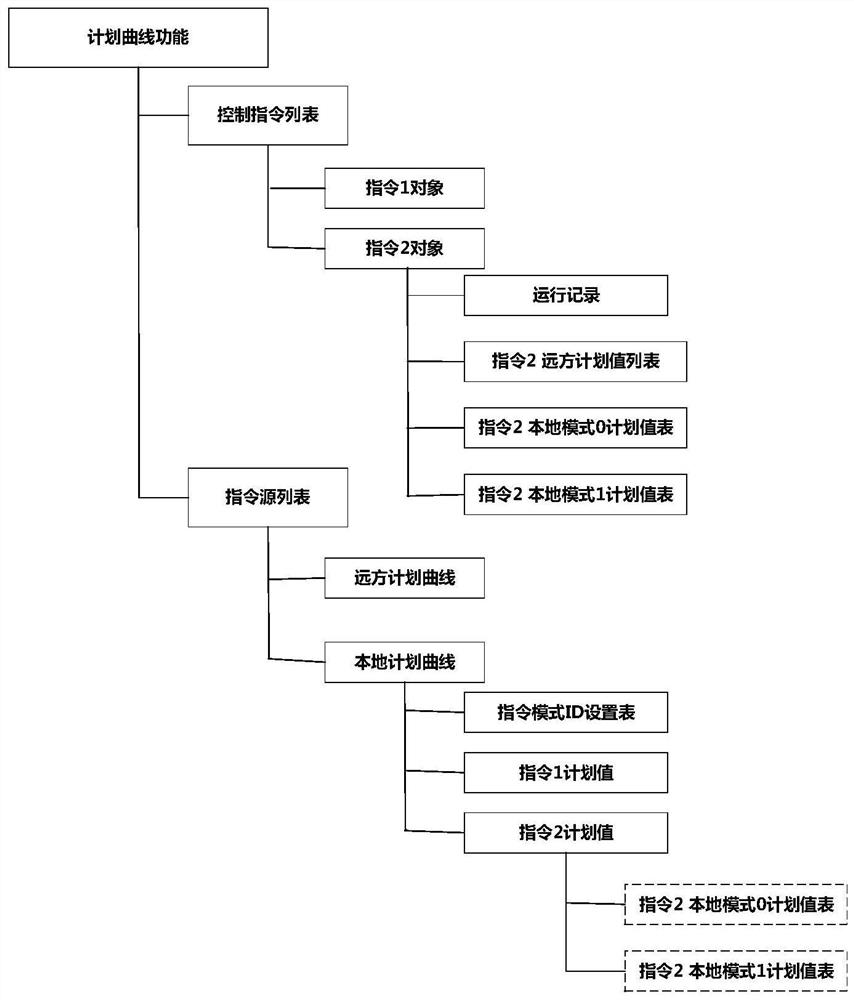

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Only configure the remote scheduling plan value curve

[0046] In the wizard function, only one remote command source is added, a planning curve model is created, and the processing strategy of each abnormal state is configured according to the operation requirements of the power plant. When the state of the remote command source is normal, the planned value curve outputs the command normally; when the state of the remote command source is abnormal, the exception processing is carried out according to the triggered exception handling strategy.

[0047] When the "Skip current command" strategy is triggered, the planning curve module keeps the last value unchanged, but keeps the on-duty status unchanged; when the "Block planning curve" strategy is triggered, it stops sending the planning curve command value and sets the blocking flag . When the "switch abnormal instruction" strategy is triggered, since there is no switchable instruction, it is processed accord...

Embodiment 2

[0048] Example 2: Configure only the local plan value curve

[0049] In an offline microgrid or energy storage power station, generally only one local command source is added to the wizard function, a planning curve model is created, and the processing strategy for each abnormal state is configured according to the operation requirements of the power plant.

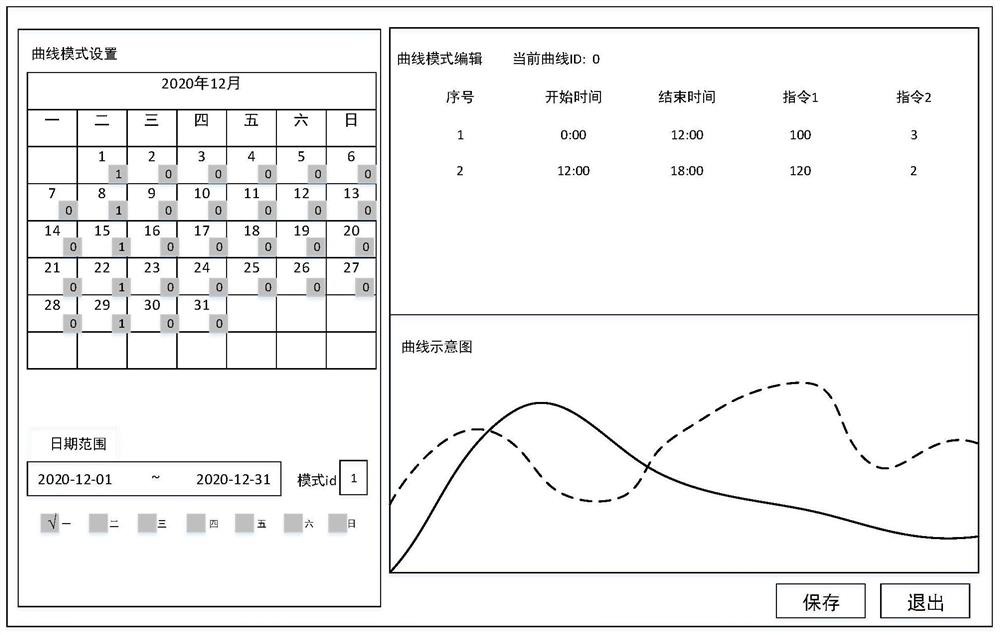

[0050] When the communication between the power plant and the dispatcher is interrupted, or the dispatcher command source is invalid, the local planning curve needs to be used. Multimodal local planning curves based on calendar patterns, such as image 3 shown. Proceed as follows:

[0051] First, under the local command source, configure multiple pattern curve objects according to the number of planned curve patterns to be used. Different pattern curve objects are distinguished by corresponding IDs.

[0052] Second, configure the control instruction data sets of different time periods from 00:00 to 24:00 for each mode ...

Embodiment 3

[0056] Example 3: Configure the remote planned value curve and the local planned value curve

[0057] In the wizard function, multiple remote command sources and a local command source can be added, a planning curve model can be created, and the processing strategy of each abnormal state can be configured according to the operation requirements of the power plant.

[0058] The program receives the remote planning curve in real time and updates the local planning curve value from the local settings. When the remote command state is abnormal and needs to be switched, the command source switching logic is started.

[0059] like Figure 4 Shown is a schematic flow chart of the logic method for multi-level instruction source switching. The detailed steps are as follows:

[0060] First, determine whether to enable the automatic switching logic of command source switching. If it is not enabled, it means that according to the remote on-site pressure plate and command source set ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com