Viscous organic material drying device

A technology of organic matter and chemical equipment, which is applied in the direction of dryers, climate change adaptation, drying rooms/containers, etc., can solve the problems of increasing the risk of material jams, increasing processing time, and limited drying effect, so as to achieve no risk of material jams , improve efficiency and effect, and fully dry the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below with reference to the accompanying drawings.

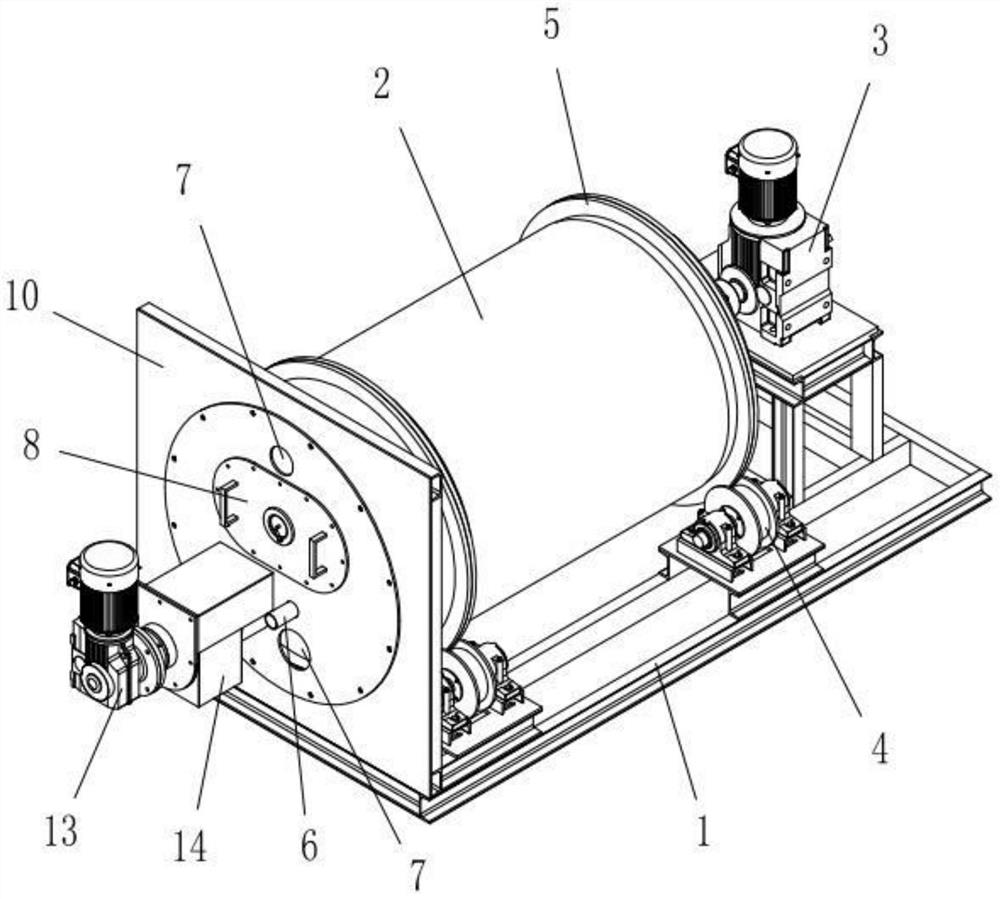

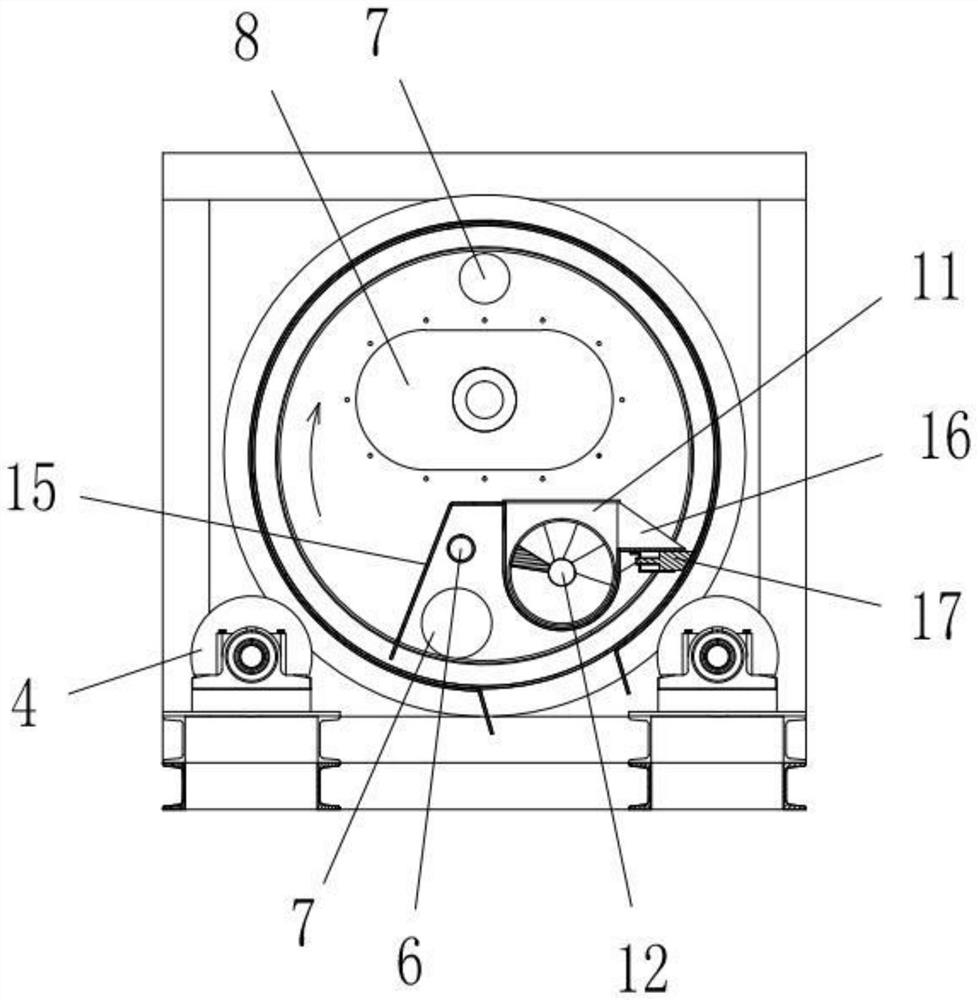

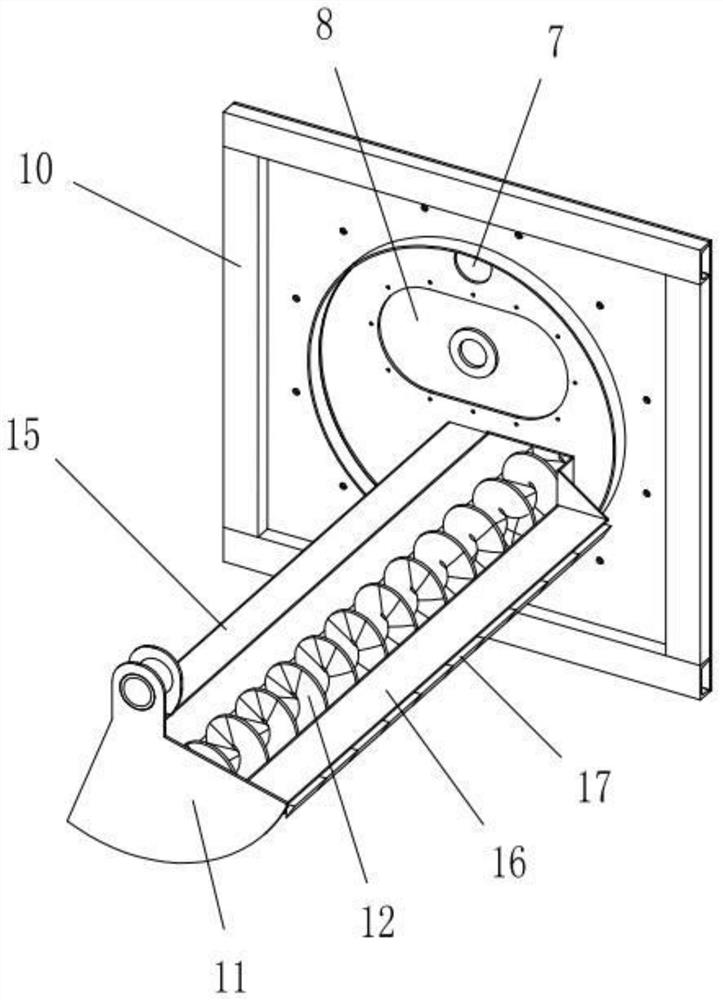

[0017] as attached Figure 1-3 As shown in the figure, a drying device for viscous organic materials according to the present invention includes a frame 1, a drum 2, a drum driving device 3 and a screw feeding mechanism; the frame 1 is provided with a supporting vertical plate 10 and a plurality of groups of rolling The support assembly 4, the support vertical plate 10 is located at one end of the frame 1, the front and rear ends of the drum 2 are provided with rolling rings 5, the frame 1 is provided with four groups of rolling support assemblies 4, and the four groups of rolling support assemblies 4 are respectively arranged at At the four corners of the drum 2 , each rolling ring 5 is matched with two sets of rolling support assemblies 4 . The rolling support assemblies 4 include roller brackets, bearings and small rollers to ensure the rotational stability of the drum 2 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com