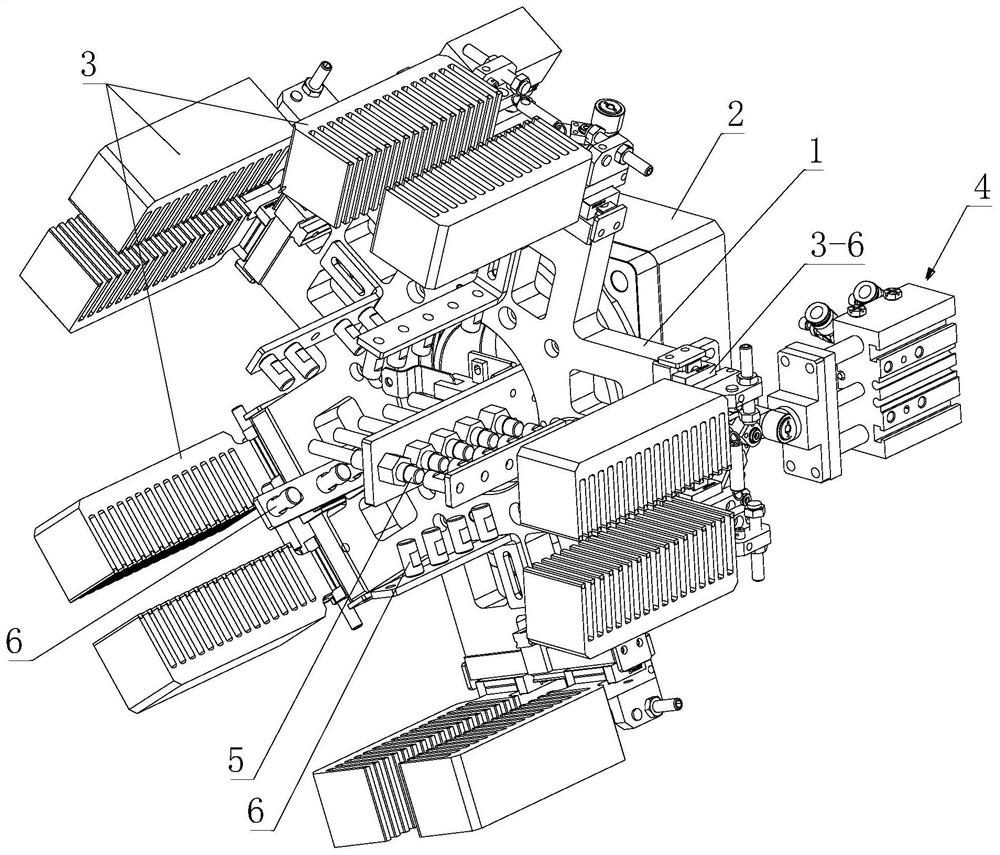

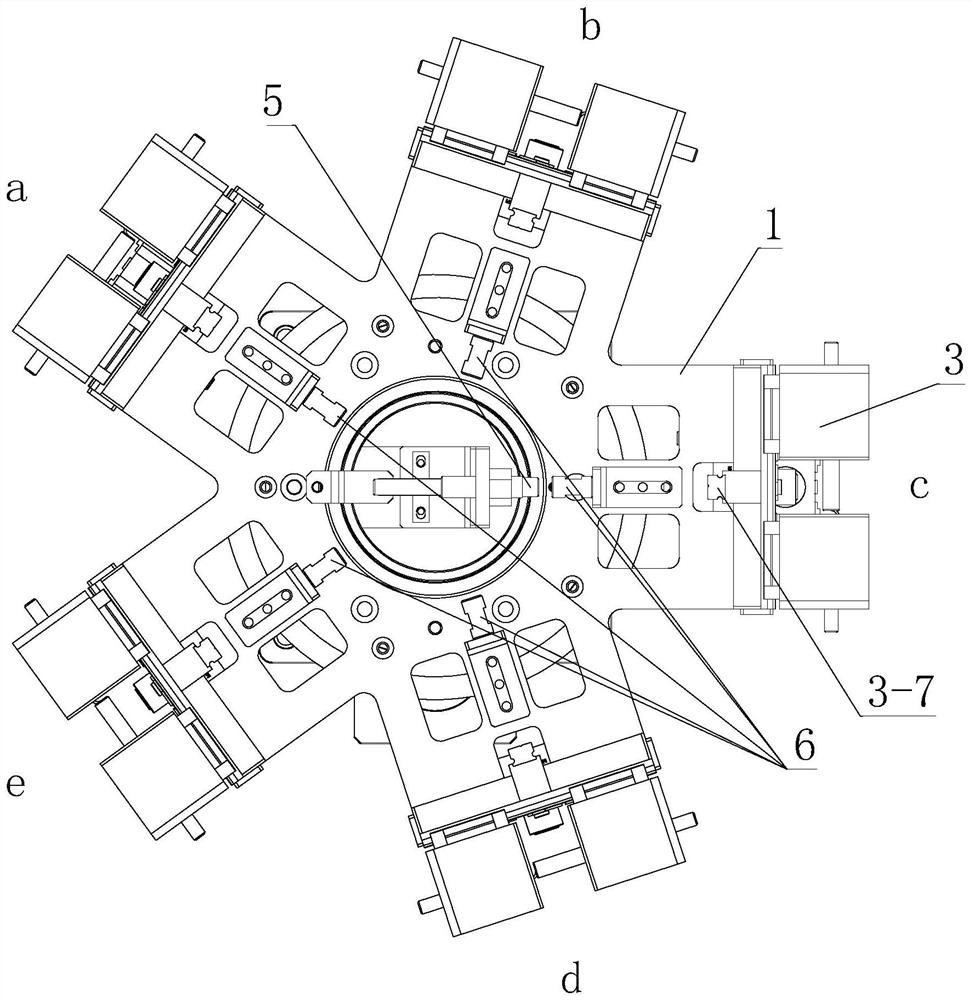

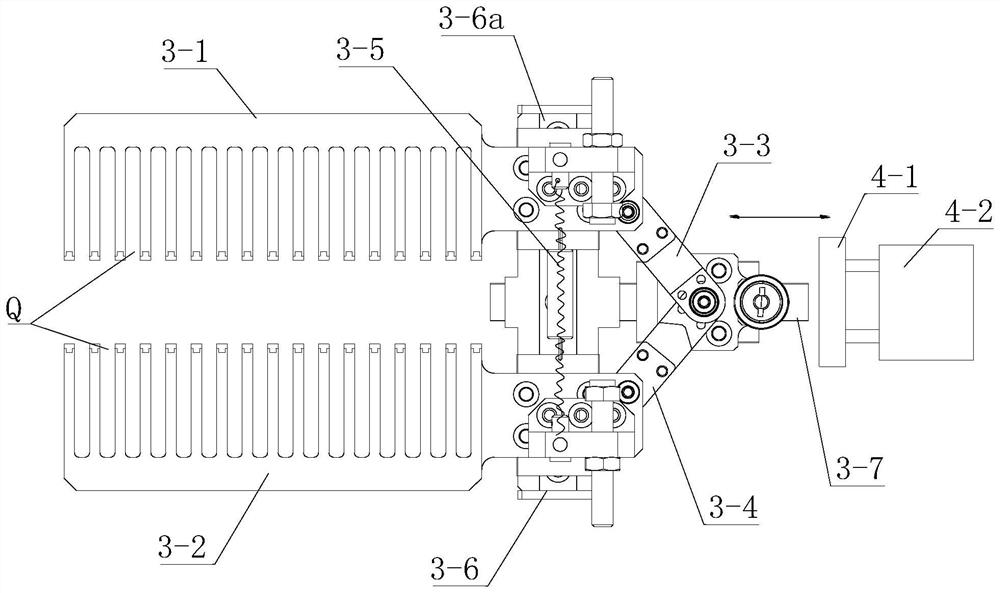

Battery cell conveying mechanism

A transmission mechanism and electric core technology, applied in the direction of conveyor objects, conveyor control devices, climate sustainability, etc., can solve the problems of inconsistency, narrow space, etc., and achieve the effect of solving the problem of transportation and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings. When describing the embodiments of the present invention in detail, for the convenience of explanation, the drawings representing the device structure will not be partially enlarged according to the general scale, and the schematic diagrams are only examples, which should not be limited here. The scope of protection of the present invention. It should be noted that the accompanying drawings are in a simplified form and all use inaccurate scales, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention. Meanwhile, in the description of this application, the terms "first", "second", etc. are only used to distinguish the description, and cannot be understood as indicating or implying relative importance or implicitly indicating the number of technical features indicated; the term "" The orientation or positional r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com