Intelligent soot blowing system of air pre-heater

A technology of soot blowing system and air preheater, which is applied in the direction of combustion method, lighting and heating equipment, removal of solid residue, etc., to achieve the effects of equipment integration, fast timeliness and large detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

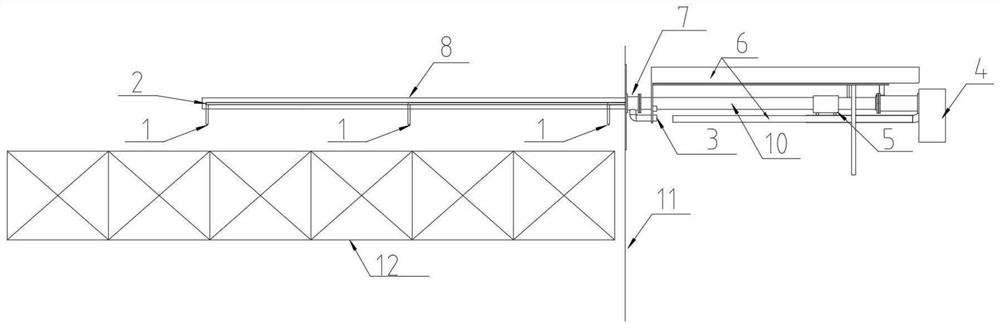

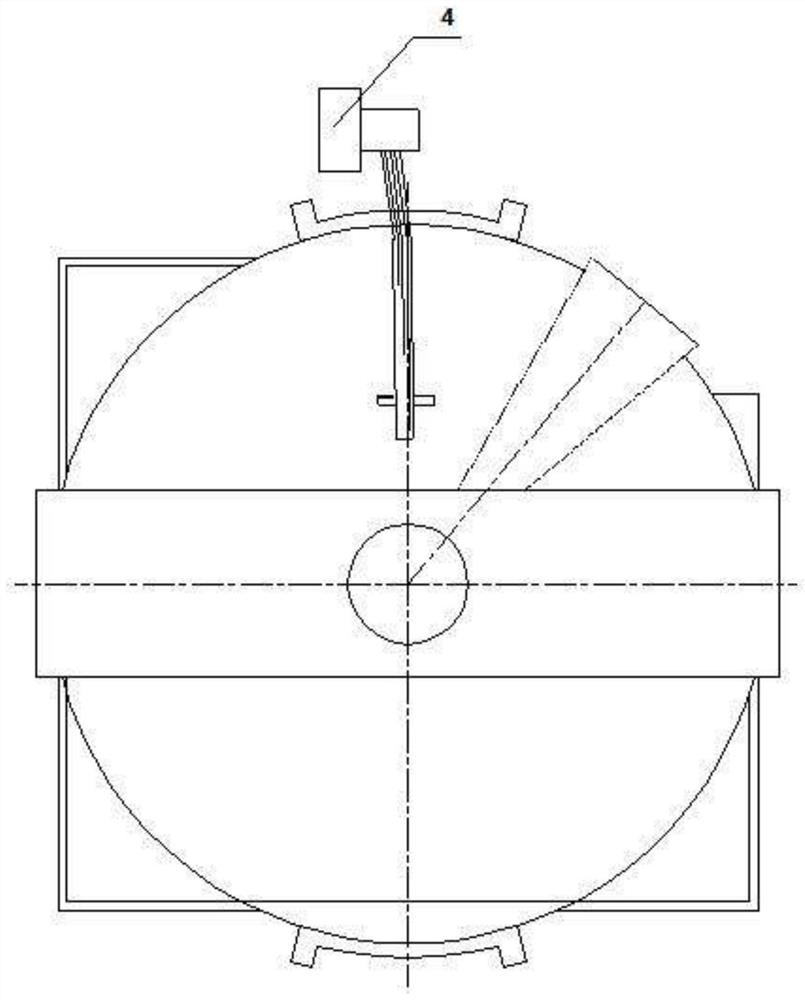

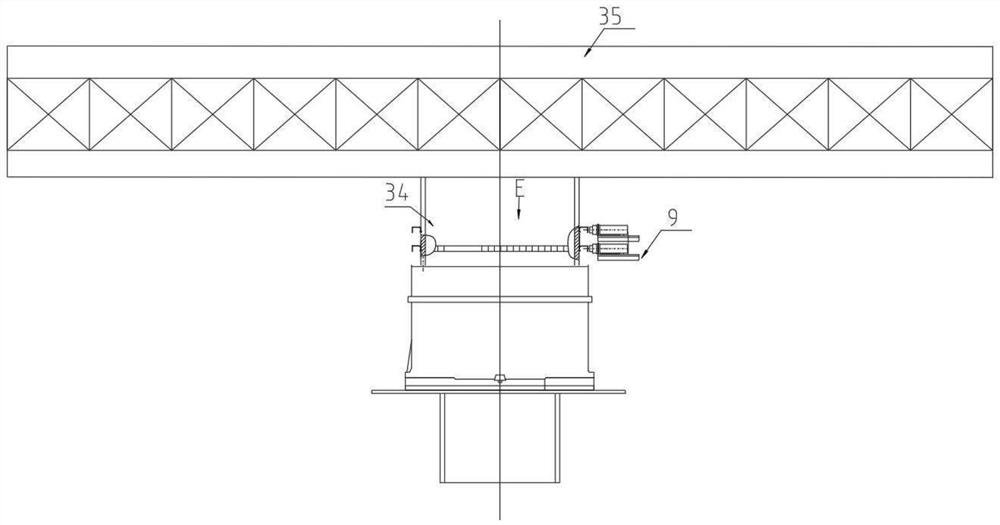

[0044] like Figures 1 to 9 As shown, in a preferred embodiment, the present invention provides an air preheater intelligent soot blowing system, comprising a heat transfer element clogging detection module, a soot blowing module and a visual monitoring module, the heat transfer element clogging detection module is used for Detect the specific location of the blockage of the heat transfer element of the air preheater, the soot blowing module is used to purge and clean the blockage in the heat transfer element, and the visual monitoring module is used to monitor the blockage and loss of the heat transfer element of the air preheater in real time. and the surface temperature of the heat transfer element;

[0045] The soot blowing module includes a soot blower 21, a purging medium supply device and a main control cabinet 23. The soot blower 21 includes a soot blowing gun barrel, an external telescopic tube 20, an external sports car 18, a wall box 19, an external sealing sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com