Bearing assembly

A technology of bearing components and shaft parts, applied in the direction of bearing components, bearings, shafts and bearings, etc., can solve the problems of linear bearing failure, sliding friction, unsuitable guide rail rotation movement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

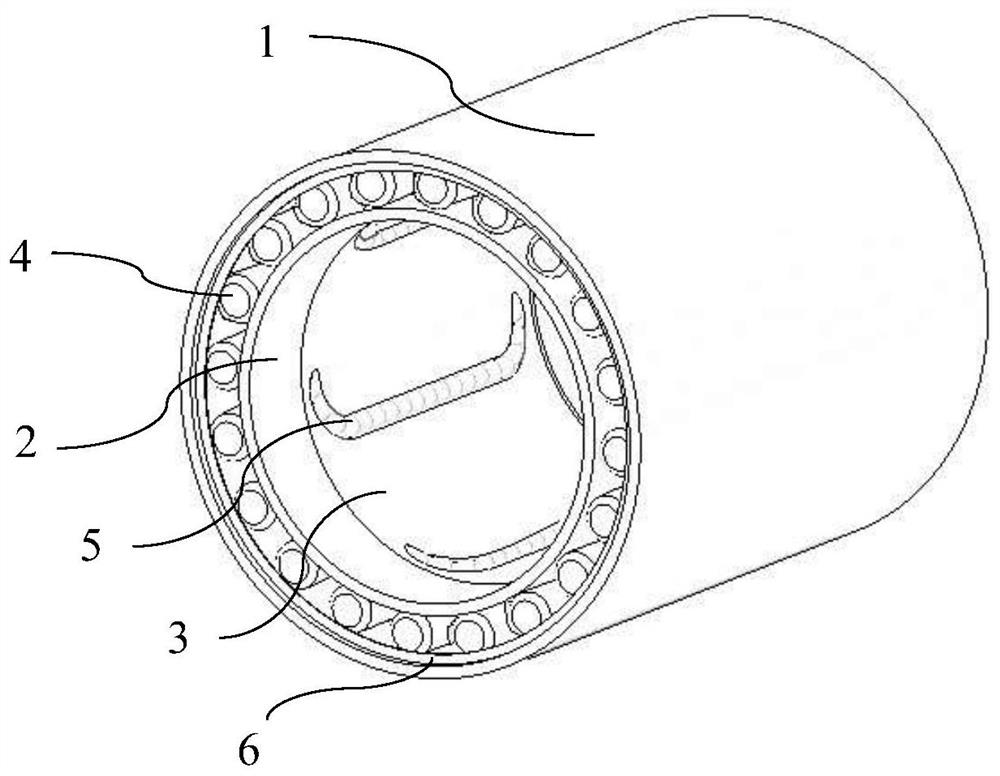

[0024] figure 1 A schematic perspective view of a bearing assembly according to a preferred embodiment of the present invention is shown. figure 2 shows according to figure 1 A cross-sectional view of an axial section of the bearing assembly. The bearing assembly can be fitted onto a shaft element not shown here, in particular an optical shaft.

[0025] combine figure 1 and figure 2 It can be seen that the bearing assembly mainly includes an outer ring 1 , an inner ring, a plurality of first rolling bodies 4 and a plurality of groups of second rolling bodies 5 arranged coaxially.

[0026] In this embodiment, the inner ring has a split structure. Specifically, the inner ring includes a first inner ring member 2 and a second inner ring member 3 . Here, the outer ring 1 , the first inner ring member 2 and the second inner ring member 3 are arranged coaxially with each other, wherein the first inner ring member 2 and the second inner ring member 3 are arranged radially ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com