Three-oil-cylinder pipe column clamping device for iron roughneck

A technique of clamping pipes and iron drillers, applied in the direction of drill pipes, casings, drill pipes, etc., can solve the problems of jaw crushing, damage, pipe string deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

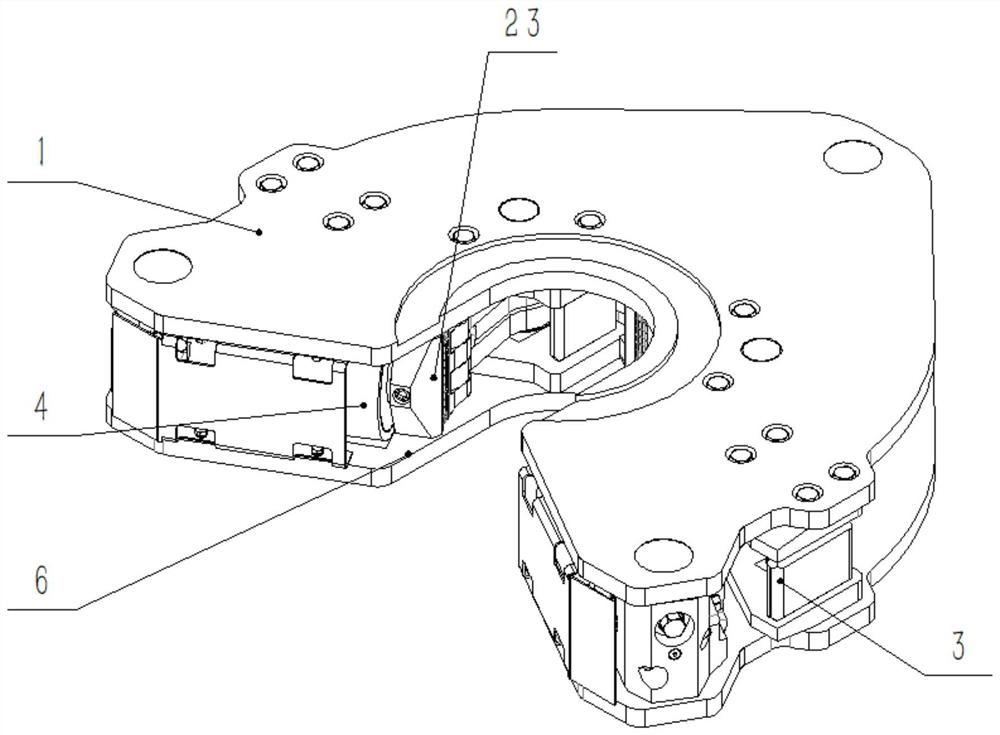

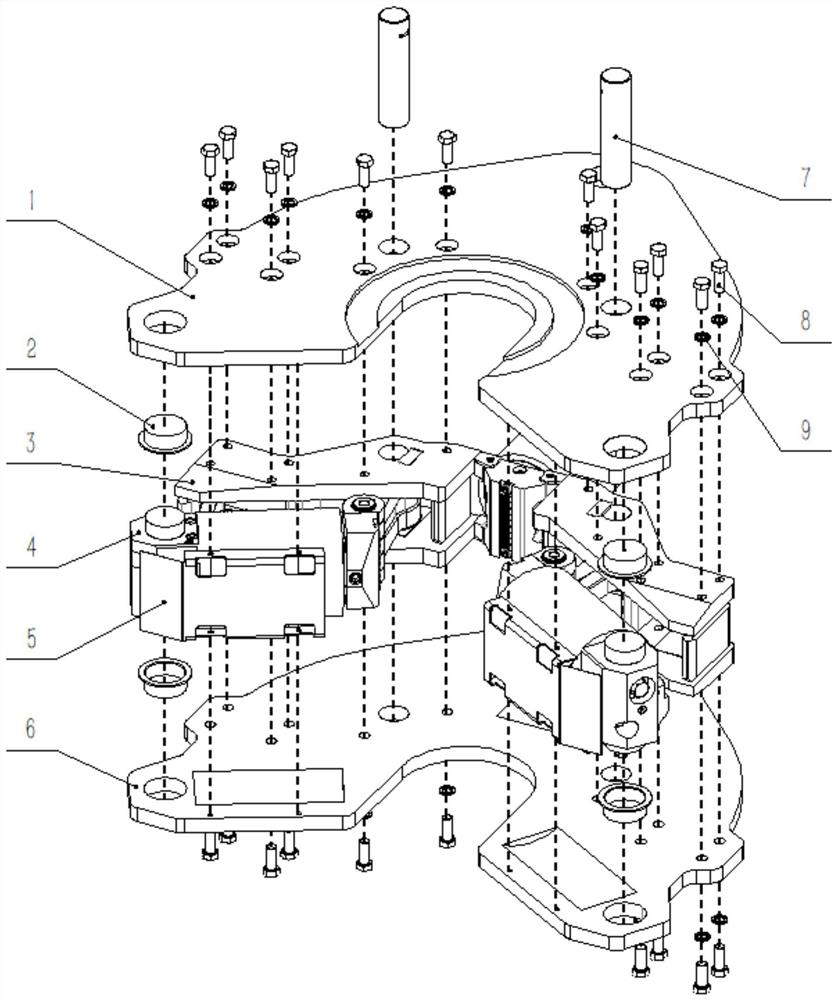

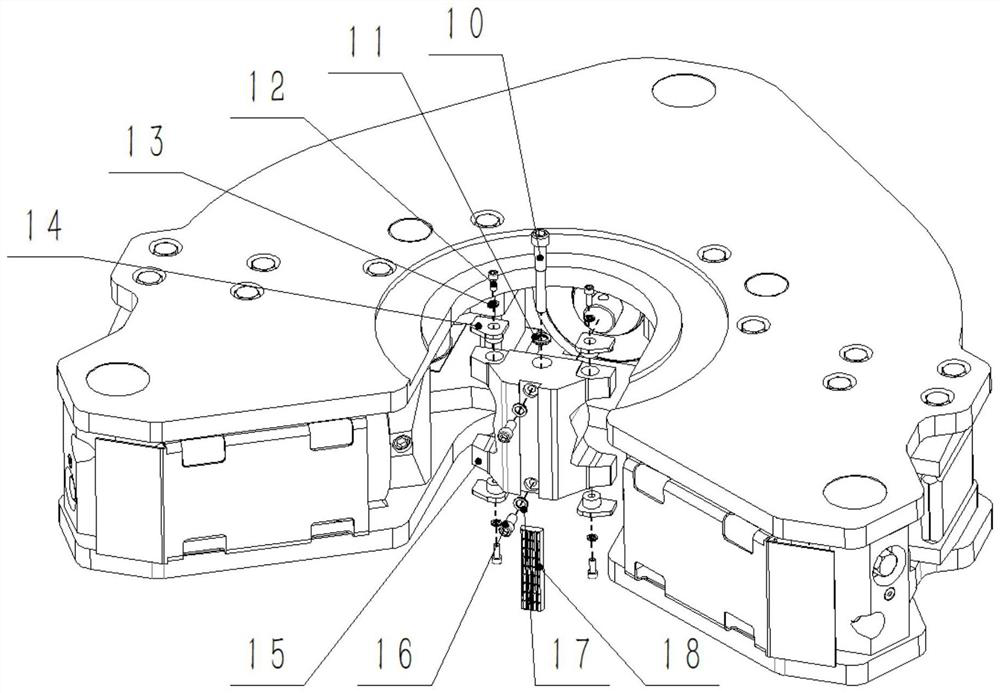

[0022] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

[0023] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes an upper cover plate 1, six oil cylinder bushings 2, two brackets 3, three jaw oil cylinders 4, two guard plates 5, a lower bottom plate 6, two pins I7, and twenty-four bolts Ⅰ8. Twenty-four wedge washers Ⅰ9, positioning bolts Ⅰ10, wedge washers Ⅱ11, four bolts Ⅱ12, four wedge washers Ⅲ13, four wear blocks 14, jaw seat Ⅰ15, six bolts III16, six wedge washers IV17, three jaws 18, two shoulder retaining rings 19, two pins II20, four wear-resistant bushings 21, two bolts IV22, two jaws II23, two It is characterized in that: the two brackets 3 are respectively connected with the upper cover plate 1 and the lower bottom plate 6 through twenty-four bolts I8 and twenty-four wedge-type washers I9; The three jaw oil cylinders 4 are evenly arranged between the upper cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com