Full automatic hydraulically operated fixture device

A hydraulic fixture, fully automatic technology, applied in the direction of positioning devices, clamping, manufacturing tools, etc., can solve the problems of low production efficiency, high labor intensity of operators, etc., achieve high installation and positioning accuracy, avoid complicated procedures, and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

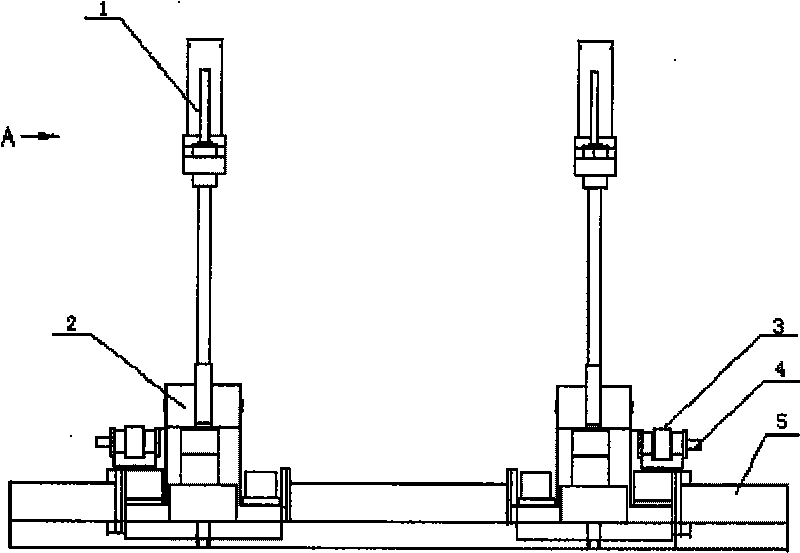

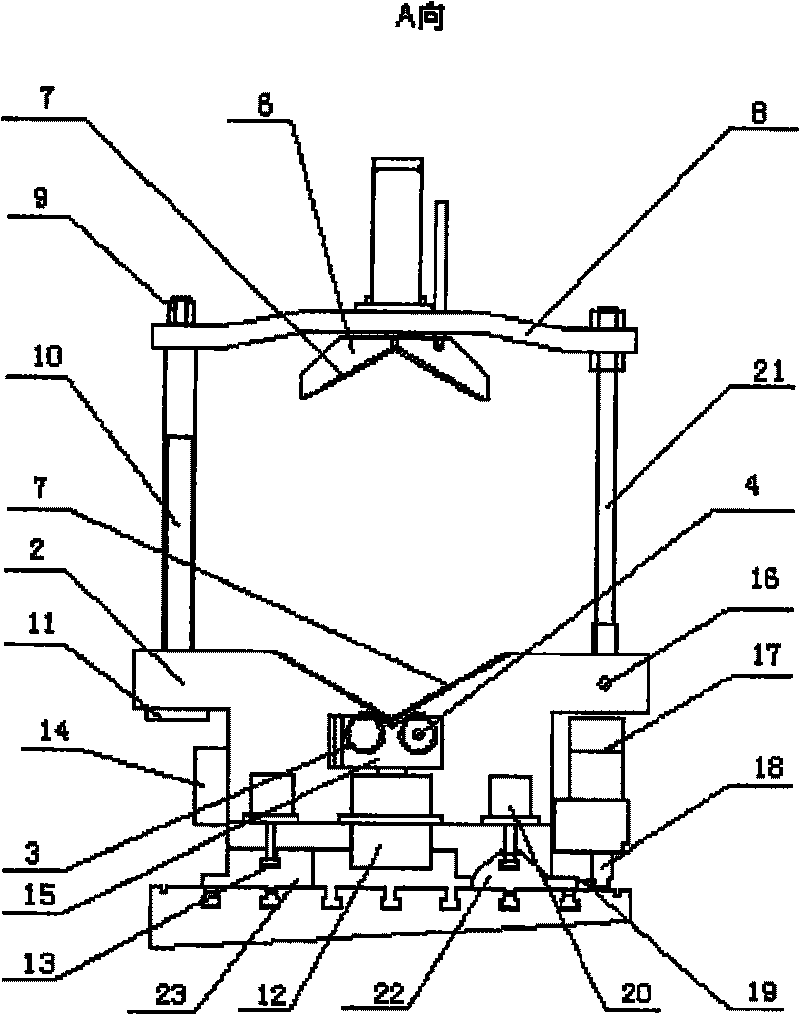

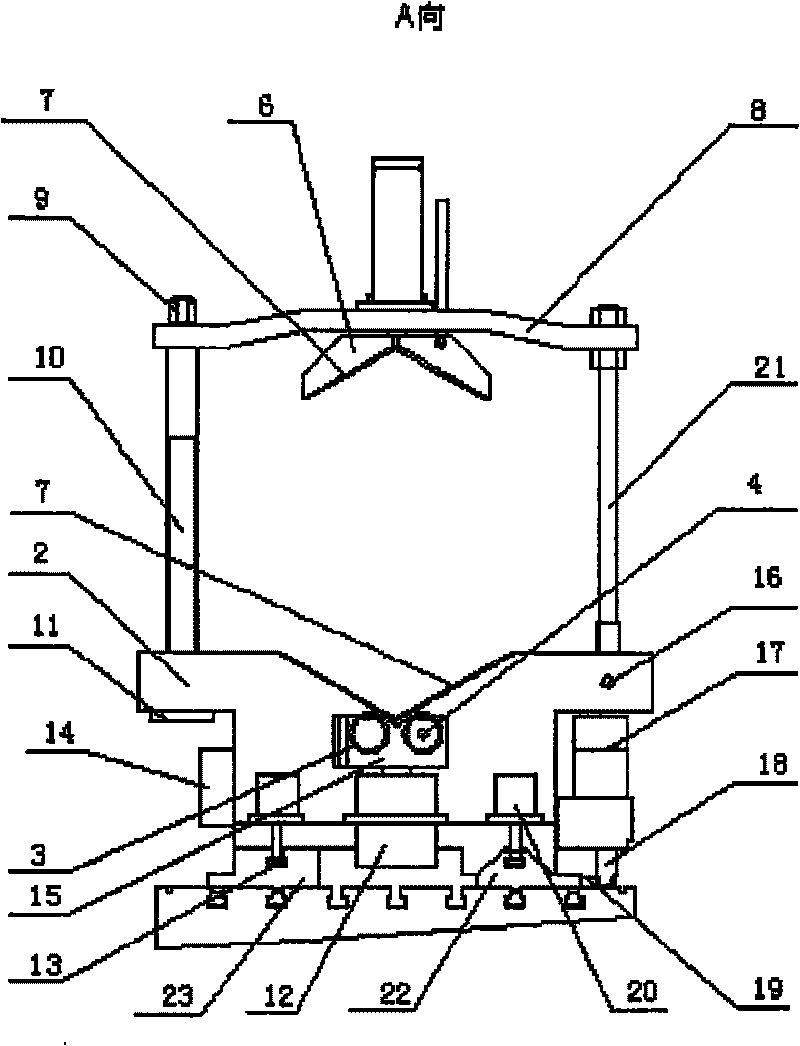

[0022] The present invention will be further explained below in conjunction with the drawings:

[0023] Such as figure 1 , 2 As shown, the fully automatic hydraulic clamping device of the present invention includes two clamping bodies for clamping shaft parts on a worktable, and a "rectangular" guide rail 23 and a "mountain-shaped" guide rail 22 fixed on the worktable and arranged in parallel. The base 2 of the clamp body is set on the guide rail. The bottom of the base 2 is provided with a flat guide surface and a groove of the "mountain-shaped" guide rail 22 that are matched with the "rectangular" guide rail 23 and the "mountain-shaped" guide rail 22. The workpiece supporting surface of each clamp body base 2 is a "V-shaped" groove with an upward opening, and the included angle of the two bottom surfaces of the "V-shaped" groove may be 120°; the clamping mechanism matched with the clamp body is set in The base (2) above the "V-shaped" groove; the clamping mechanism includes a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com