Automatic packaging bag stacking device with dust collection function

A palletizing device and packaging bag technology, which is applied in the direction of object stacking, transportation and packaging, loading/unloading, etc., can solve the problems of increased operating costs, heavy burdens on enterprises, and heavy workloads on staff, and reduce the workload of operations , reduce the intensity of work, reduce the effect of secondary dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

[0044] like Figure 1-11 As shown, this application provides:

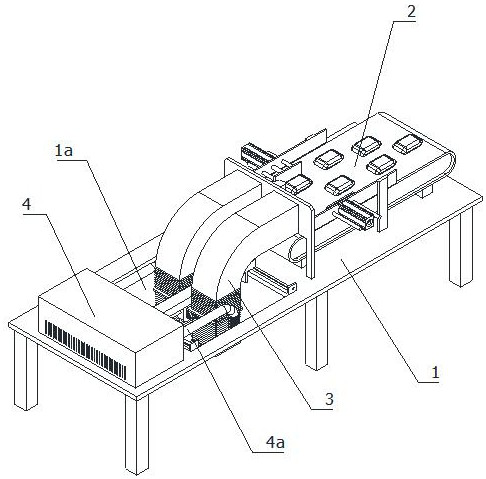

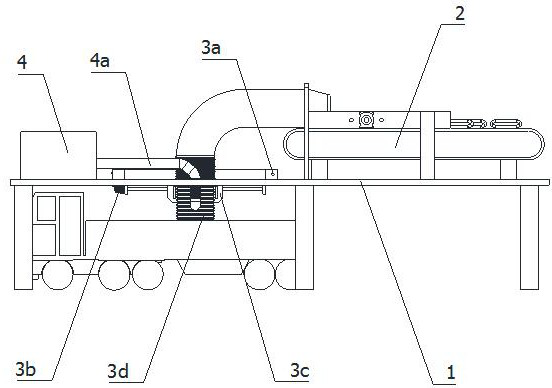

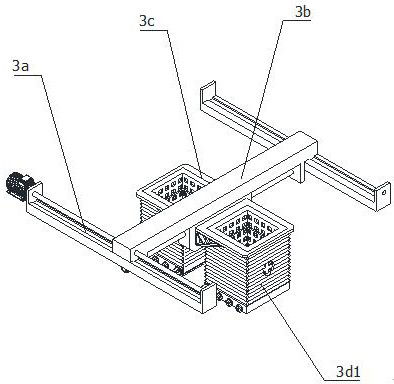

[0045] An automatic stacking device for packaging bags with vacuuming function, comprising a frame 1, a conveyor belt 2 arranged on the frame 1, a stacking mechanism 3 and a dust suction mechanism 4, the frame 1 is provided with a rectangular slot 1a, The stacking mechanism 3 includes a first drive assembly 3a, a second drive assembly 3b, a mounting frame 3c and a palletizing assembly 3d. The first drive assembly 3a is located in the rectangular slot 1a, and the second drive assembly 3b is slidably located in the first drive assembly 3a. The first drive assembly 3a is used to drive the sliding of the second drive assembly 3b, the mounting frame 3c is sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com