Intelligent dismounting equipment for insert injection molding terminal

An insert injection molding and terminal technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of damage to the terminal body, difficulty in separating the injection mold from the terminal body, etc., and achieve the effect of saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

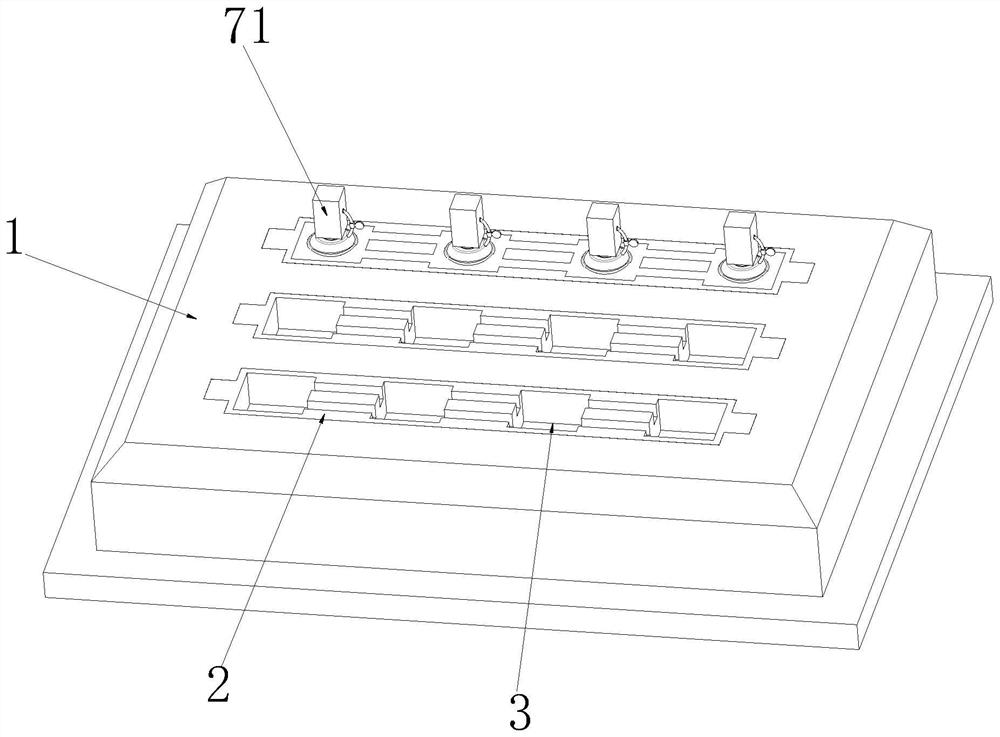

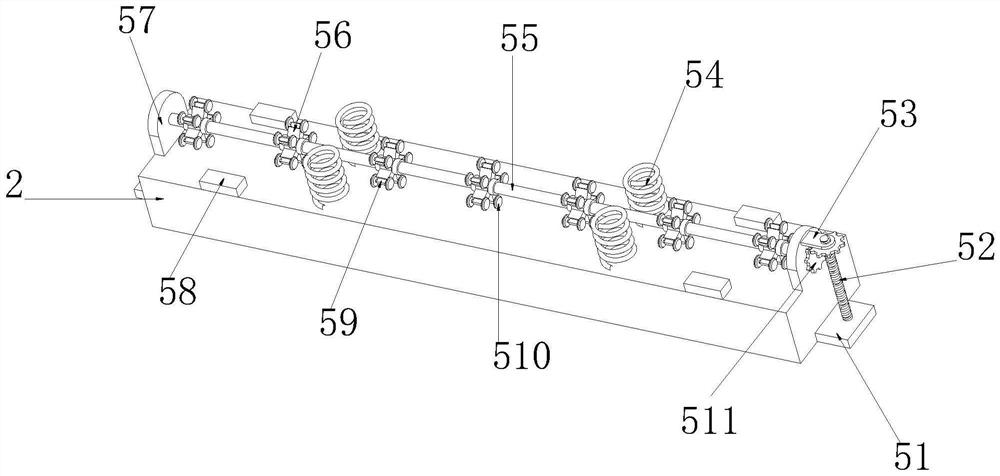

[0035] see Figure 3-4As shown in the figure, an intelligent disassembly device for inserting injection-molded terminals includes an injection mold 1, an injection-molded terminal shell 2, a terminal groove 3 and a terminal body 4. The injection-molded terminal shell 2 is connected to the upper surface of the injection-molded terminal shell 2. There are four terminal slots 3 on the surface, and the terminal body 4 is arranged inside the terminal slot 3. The lower surface of the injection-molded terminal shell 2 is integrally formed with a connecting plate 57 on both sides. The outer side wall of the knocking shaft 55 is connected with a number of evenly distributed telescopic boxes 56 through the connecting ring. The other end is connected to the inner upper surface of the telescopic box 56 through the extension spring, the extension plate 59 drives the extension spring to shrink and stretch during the movement of the position, and the inner lower surface of the injection term...

Embodiment 2

[0039] see Figure 5-6 As shown, a movable cavity 63 is opened on the side of the inner side wall of the injection-molded terminal shell 2 close to the terminal slot 3, and a sliding groove 61 is opened on both sides of the inner side of the injection-molded terminal shell 2 close to the movable cavity 63, and the inner side wall of the injection-molded terminal shell 2 corresponds to the sliding groove 61. A movable baffle 65 is slidably connected at the position, an electric push rod 64 is connected on both sides of the inner lower surface of the movable cavity 63, one end of the electric push rod 64 is connected with a separation frame 62, and the other end is directly connected to the bottom surface of the movable cavity 63, The inner side wall of the injection-molded terminal shell 2 is provided with a side sliding cavity at the position corresponding to the movable baffle 65, and the inner lower surface of the injection-molded terminal shell 2 is provided with a bottom sl...

Embodiment 3

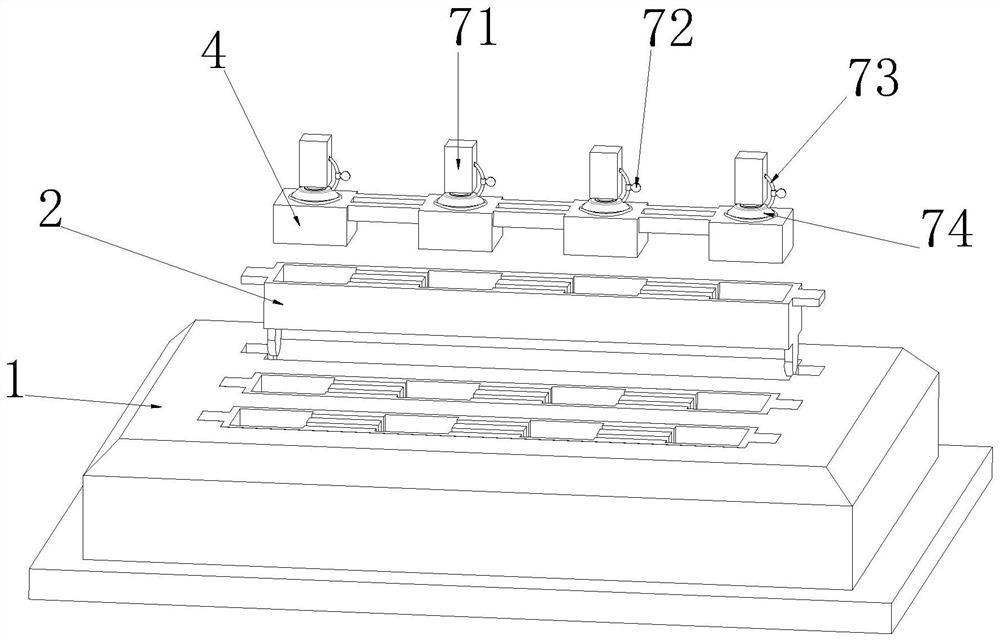

[0042] see Figure 1-2 As shown, the upper surface of the injection mold 1 is provided with a connection box 71 above the injection terminal shell 2, and a suction pump is connected inside the connection box 71 at the position corresponding to the suction cup 74, and the suction pump is connected with the suction cup 74 through the air duct 73. The lower end of the connection box 71 is connected with a suction cup 74, the outer side wall of the connection box 71 is connected with an air duct 73, the outer side wall of the air duct 73 is connected with a barometer 72, the upper end of the connection box 71 is connected with a tension telescopic rod through a traction rope, and the outer side wall of the traction rope is connected with a tension sensor The side of the upper surface of the injection-molded terminal shell 2 close to the terminal slot 3 is connected with an infrared distance sensor;

[0043] The air pressure data inside the suction cup 74 detected by the air pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com