Waterproof strip welding equipment capable of preventing protruding burrs

A technology for welding equipment and waterproof strips, applied in shearing machine equipment, metal processing equipment, other manufacturing equipment/tools, etc., can solve the problem of local bulge at the welding place, uneven ends of waterproof strips, and inability to ensure that two waterproof strips are exposed. Part of the same problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

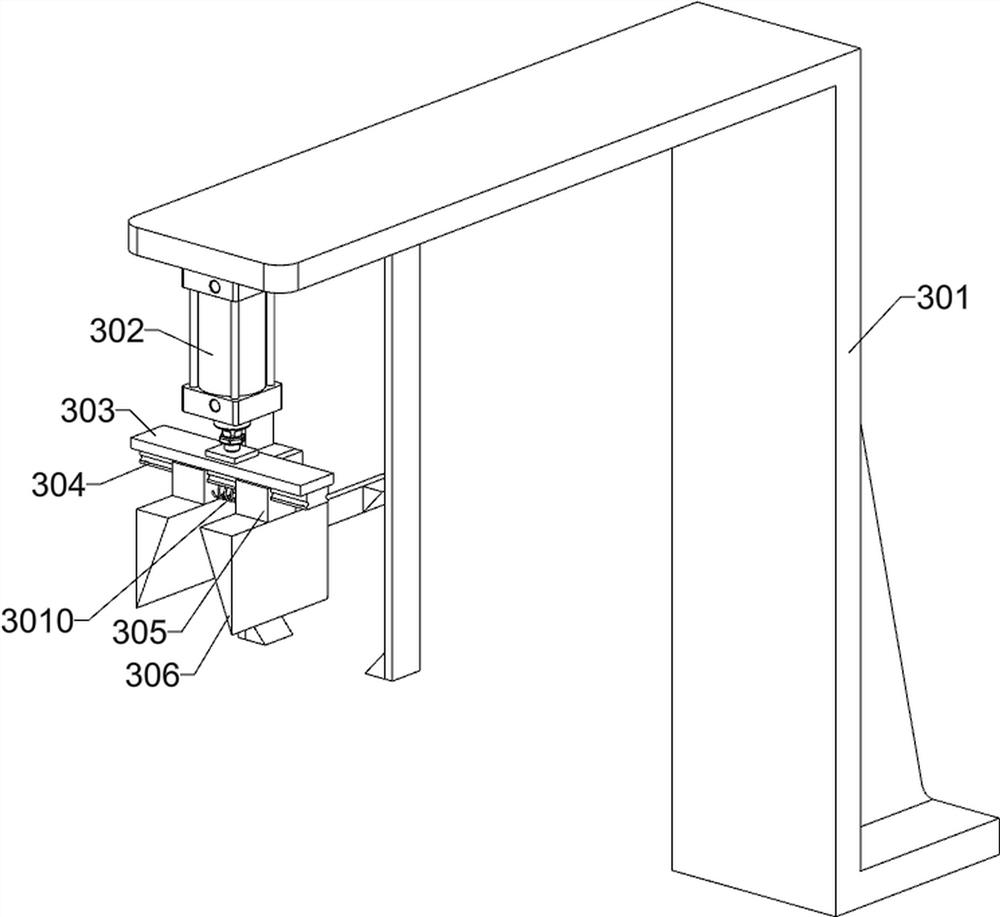

[0036] A waterproof strip welding equipment for preventing raised burrs, such as Figure 1-14 As shown, it includes a foot 1, a first mounting plate 2, a welding unit, a cutting unit and a heating and softening unit; the top of the four feet 1 is fixedly connected with a first mounting plate 2; the upper front of the first mounting plate 2 A welding unit is connected; a cutting unit is connected to the upper rear of the first mounting plate 2 ; a heating and softening unit is connected to the upper side of the first mounting plate 2 ; the cutting unit is connected to the heating and softening unit.

[0037] The welding unit includes a first mounting frame 201, a motor 202, a second mounting plate 203, a first double helix screw 204, a third polished rod 205, a welding assembly 206 and a first gear 207; the upper front part of the first mounting plate 2 Two second mounting plates 203 are fixedly connected to the upper side of the first mounting frame 201 by bolts, and the two s...

Embodiment 2

[0045] On the basis of Example 1, as figure 1 and Figure 15-18 As shown, it also includes a tensile detection unit; the upper side of the first mounting plate 2 is connected with a tensile detection unit; The first electric push rod 504, the rod sleeve 505, the twelfth installation plate 506, the third gear 507, the thirteenth installation plate 508, the first spring telescopic rod 509, the first block 5010, the second block 5011, the first Three wedge block 5012, fourth wedge block 5013, first transmission wheel 5014, fifth mounting frame 5015, third double helix screw 5016, second polished rod 5017, second transmission wheel 5018, fifteenth mounting plate 5019, Two spring telescopic rods 5020, a third clamping block 5021, a sixth wedge block 5022 and a fifth wedge block 5023; the upper side of the first mounting plate 2 is bolted with a fourth mounting frame 501 and a fifth mounting frame 5015, and the fifth mounting The frame 5015 is located at the rear of the fourth mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com