T-shaped steel intelligent welding workstation

A welding station and T-shaped steel technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of improving the scope of application, smooth transportation, and ensuring stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

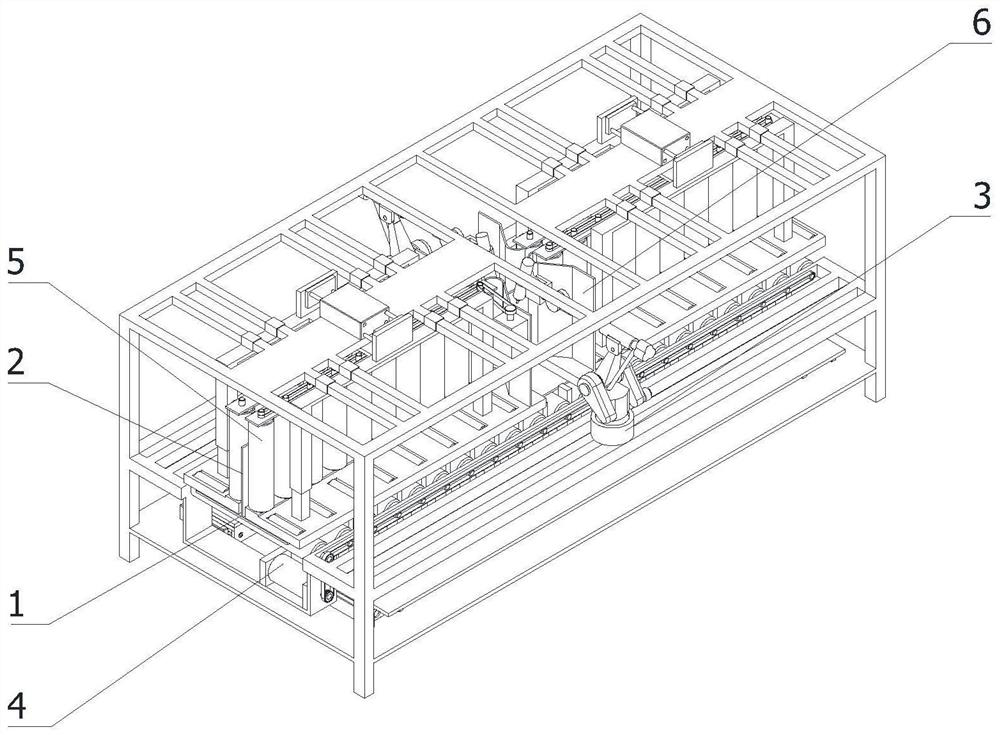

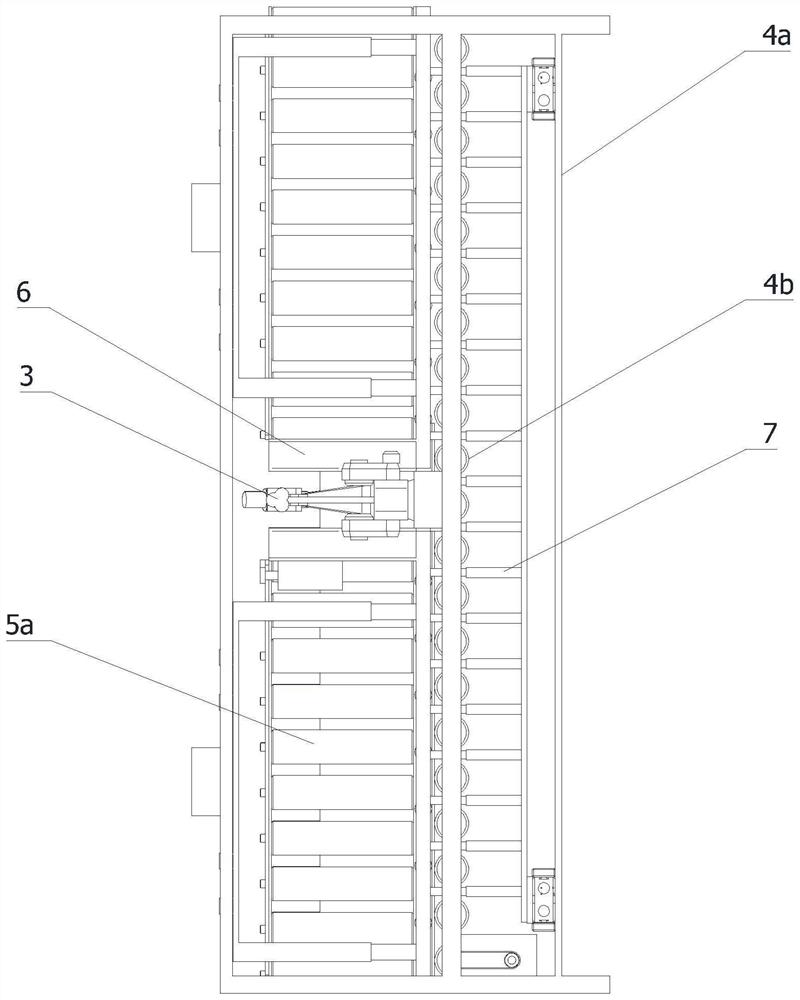

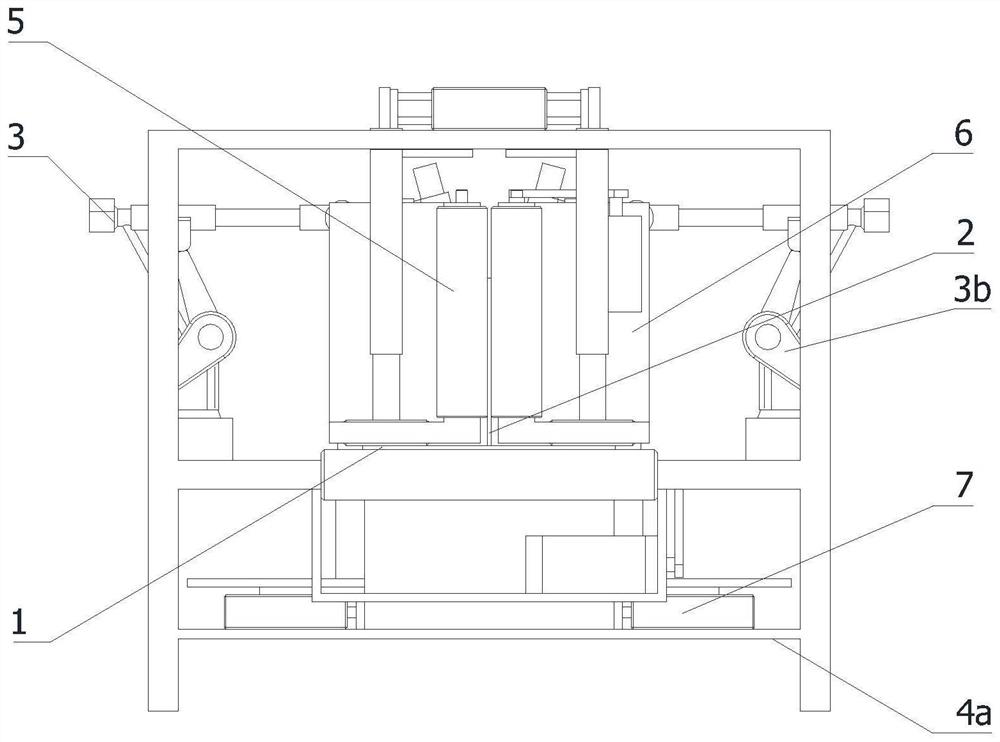

[0042] like Figure 1 to Figure 5 As shown, this application provides:

[0043] An intelligent welding station for T-shaped steel, comprising a plate conveying device used for right-angle butt joint between the flange 1 and the web 2, and a welding device 3 for welding the connection position of the flange 1 and the web 2, the plate The conveying device includes a wing plate conveying assembly 4 for horizontally transporting the wing plate 1, the web plate 2 is placed vertically on the wing plate 1, and the web plate 2 is provided with a web plate positioning assembly 5 for clamping the web plate 2 on both sides. The two ends of the plate conveying assembly 4 are respectively provided with two sets of web positioning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com