Automatic laser cutting device special for sheet metal machining

A laser cutting and sheet metal technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of wasting manpower, achieve the effects of reducing wear, stabilizing distance, saving work content and physical exertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

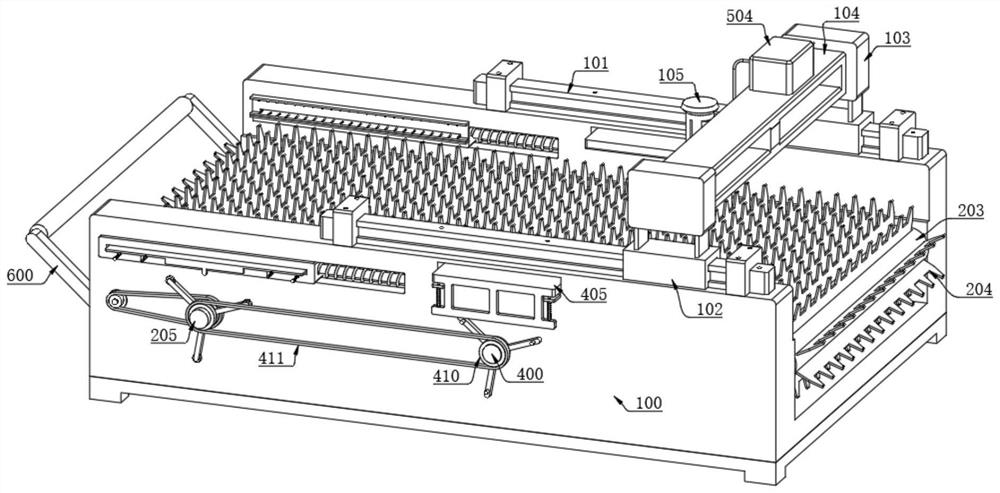

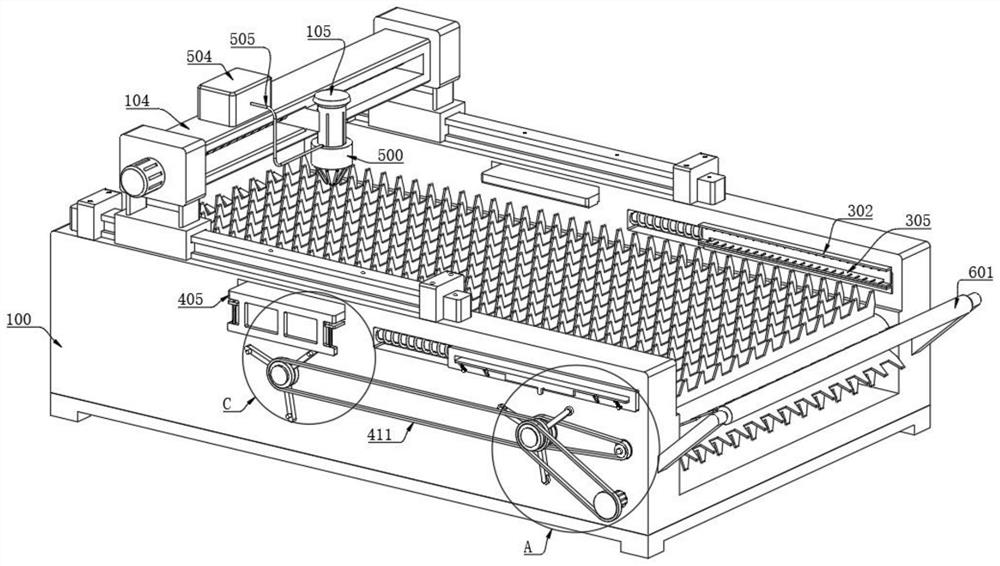

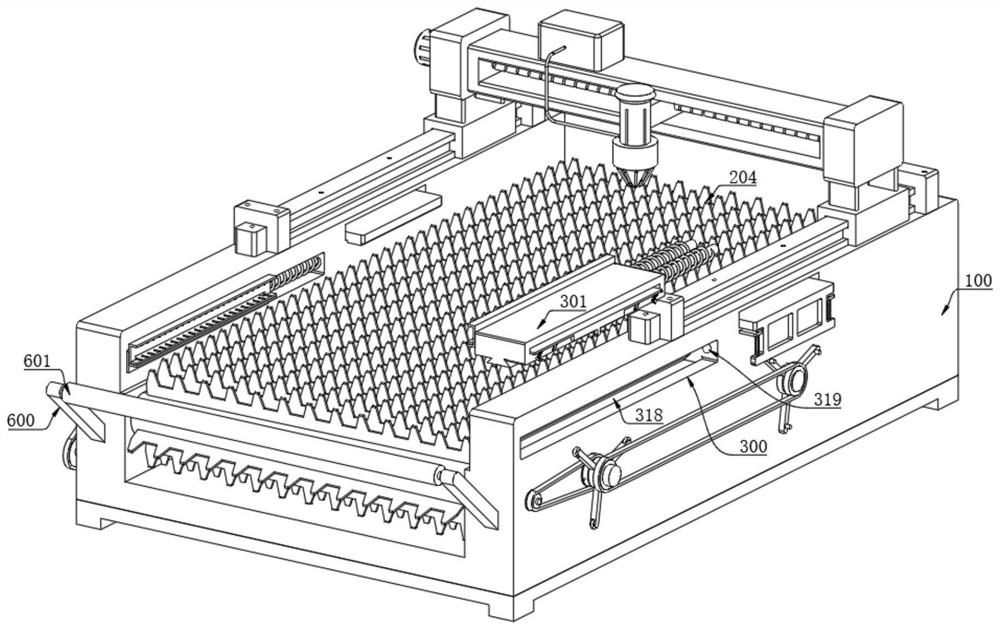

[0032] see Figure 1-11 , the present invention provides a technical solution: an automatic laser cutting device for sheet metal processing, comprising a main body 100, a laser cutter 105 is arranged on the top of the main body 100, a belt 203 is arranged inside the main body 100, and the outer side wall of the belt 203 is A plurality of support plates 204 are fixedly connected, one side of the main body 100 is provided with a driving structure for rotating the belt 203, two sides of the main body 100 are respectively provided with a first sliding channel 300, and the inside of the first sliding channel 300 is slidably connected with a first sliding channel 300. The sliding plate 301, the first sliding plate 301 is provided with a clamping structure for lifting the sheet metal part and clamping the sheet metal part, the clamping structure can follow the movement of the driving structure to move the sheet metal part in the direction of the laser cutter 105, the main body 100 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com