Multidirectional balanced gypsum plaster board coating process

A kind of gypsum board and coating technology, applied in the direction of coating, device for coating liquid on the surface, thin material processing, etc., can solve the problems of uneven coating and low coating quality, and reduce wrinkles and Raised, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

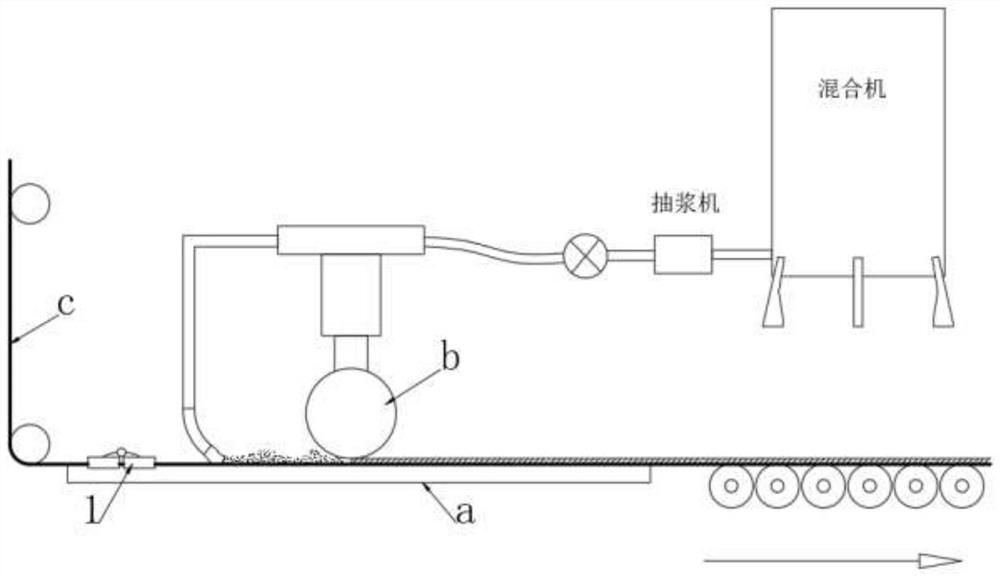

[0041] see figure 1 , in the figure a represents the working plane, b represents the coating roller, and c represents the surface paper, a multi-directional balanced gypsum board coating process, including the following steps:

[0042] S1. Install a slurry pump and a coating machine on the mixer. The slurry pump extracts the slurry from the mixer, and transfers the slurry along the conveying pipe to the front of the coating machine through the slurry transfer pump;

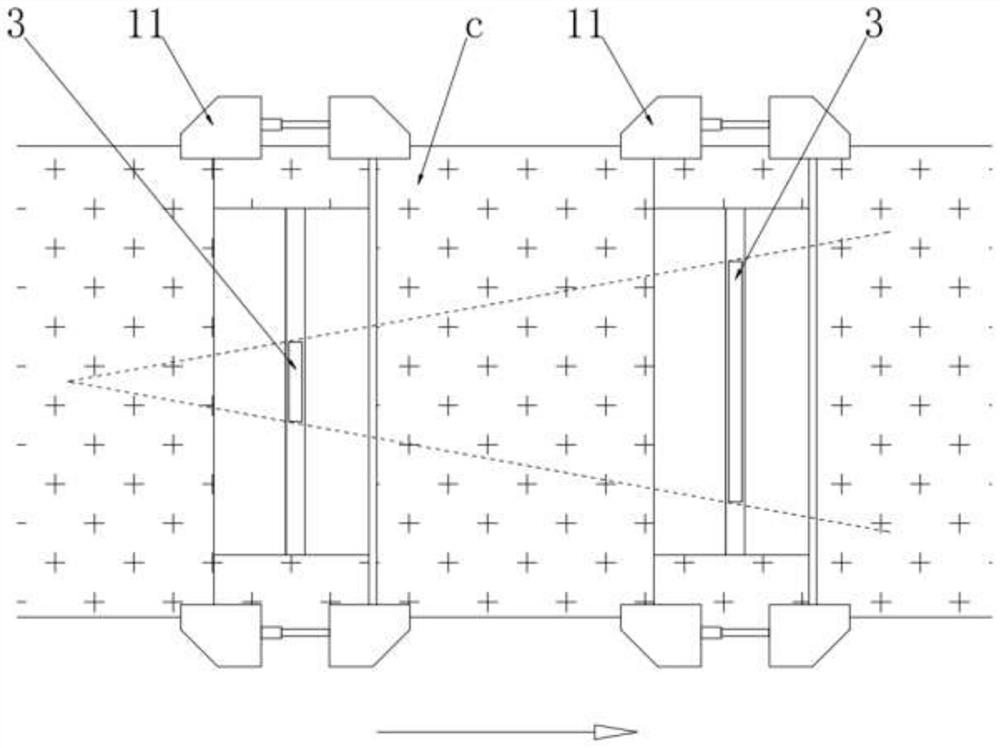

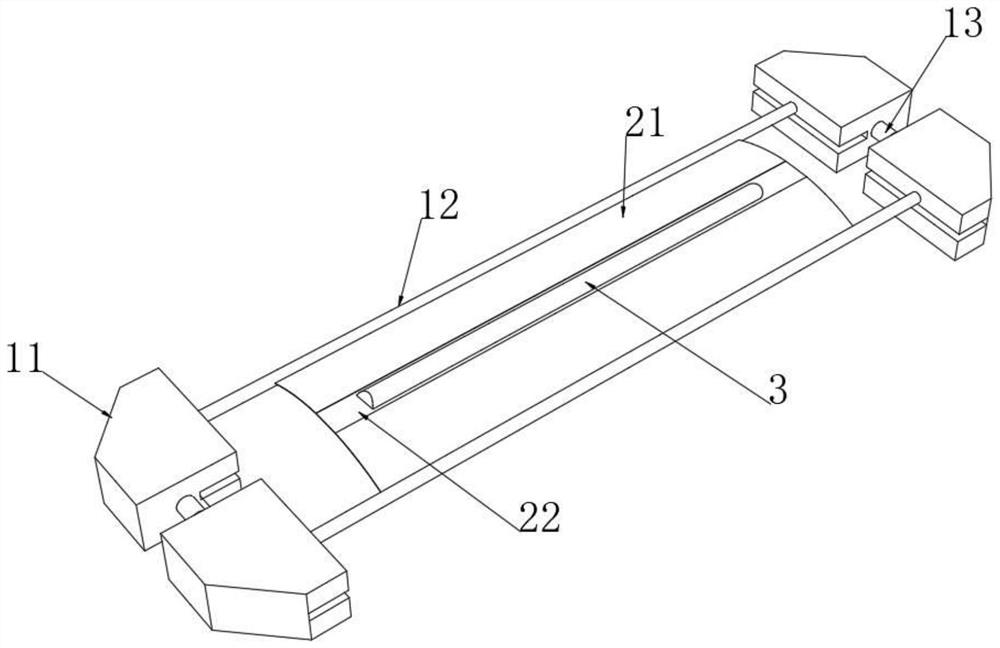

[0043] S2, see figure 2 , in front of the outlet of the conveying pipe, traverse the stroking plate 1, and make the tissue paper guided by the traction mechanism pass through the traversing stroking plate 1, such as Figure 4, control the horizontal change of the smoothing plate 1 to extend horizontally along the face paper first, so that the smoothing strip 3 and the surface of the face paper are attached to each other, and then control the contact length of the smoothing strip 3 and the paper surface to change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com