Wire harness placing rack easy to feed

A technology of placing racks and material lines, which is applied in the direction of manufacturing wire harnesses, etc., can solve the problems of unfavorable convenient and fast feeding of workers by multi-layer placing racks, and achieve the effect of improving production efficiency and speeding up feeding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

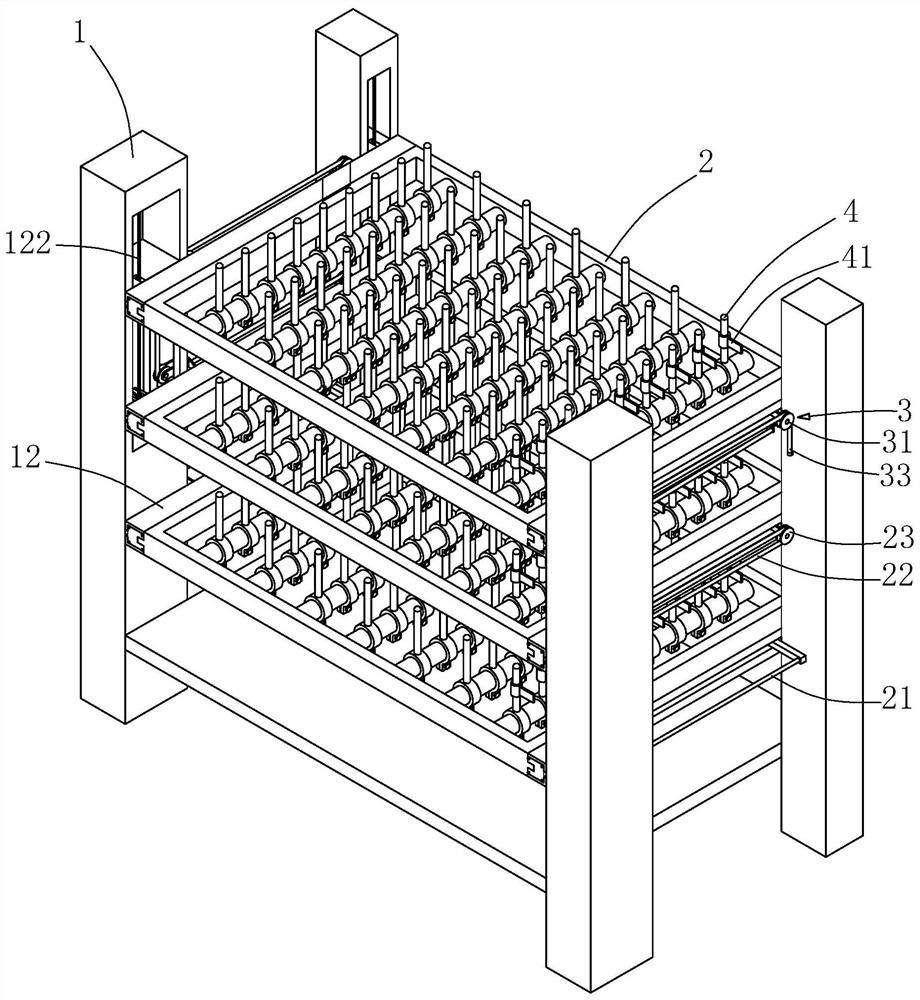

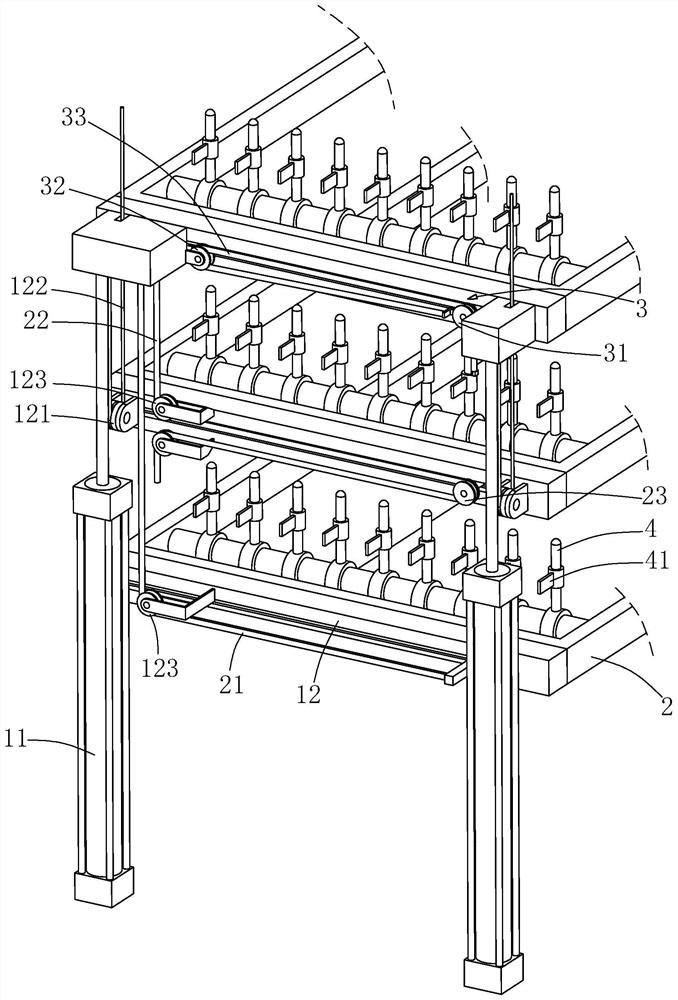

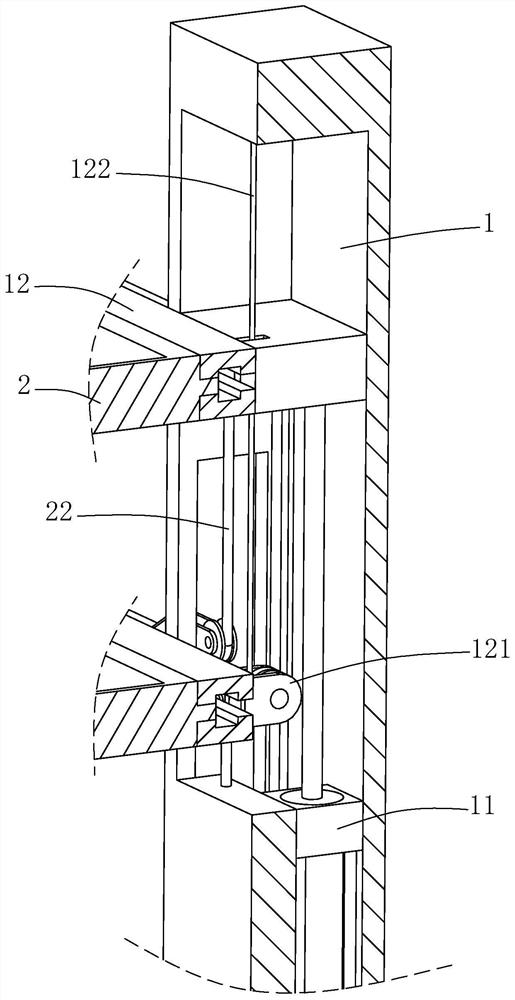

[0036] refer to figure 1 and figure 2 , including four vertically arranged uprights 1, the four uprights 1 are arranged in a rectangular array, the two uprights 1 located at both ends of the rectangle in the length direction are jointly connected with a plurality of mounting beams 12, and each end of the rectangle is provided with three horizontally arranged installations Beams 12, three mounting beams 12 at the same end are arranged in an array along the vertical direction, two mounting beams 12 far from the ground among the three mounting beams 12 at the same end are vertically sliding connected to the column 1, and one mounting beam 12 close to the ground Fixed on column 1.

[0037] refer to figure 1 and figure 2 , there are three horizontal placement layers 2 connected between the columns 1, the three placement layers 2 are arranged in an array along the height direction, the two ends of each placement layer 2 are slidably connected to the mounting beam 12, and the thre...

Embodiment 2

[0047] refer to Figure 5 and Image 6 The difference between this embodiment and the first embodiment is that one end of the second cable 22 is fixed to the end of the telescopic rod of the driving cylinder 11 that is far away from the ground, and one end of the second cable 22 that is far away from the driving cylinder 11 is fixed to the middle of the place. The layer 2 is located away from the drive cylinder 11 . The raised height of the placement layer 2 in the middle is half of the height of the telescopic rod of the drive cylinder 11, and the relative displacement between the placement layer 2 in the middle and the telescopic rod of the drive cylinder 11 is also equal to the height of the telescopic rod. 1 / 2, so the distance that the second pulling cable 22 pulls the middle placement layer 2 to slide out horizontally is also 1 / 2. In this embodiment, the structure of driving the middle placement layer 2 to slide horizontally is simpler than the structure in the first em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com