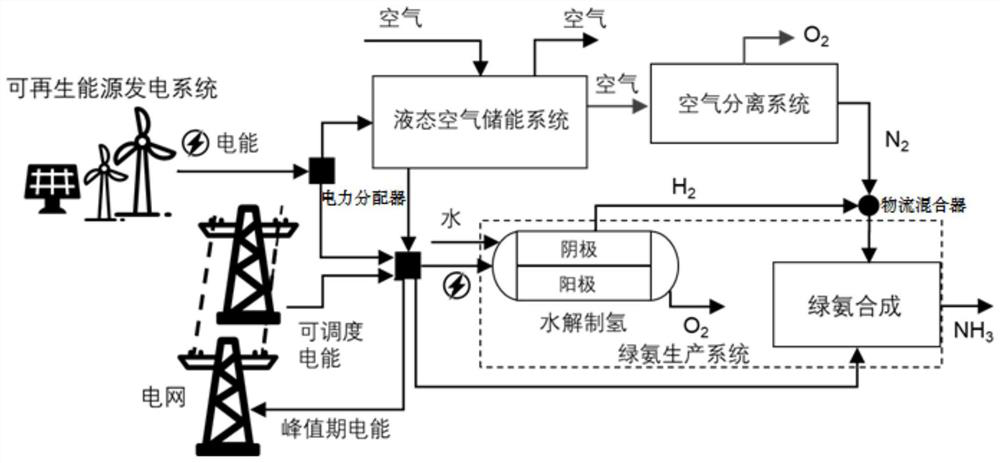

System and method for co-producing ammonia electricity by utilizing renewable energy sources

A renewable energy and production system technology, applied in the direction of ammonia preparation/separation, electrolysis components, electrolysis process, etc., can solve the problem of inability to deal with the intermittency of renewable energy, the inability to realize device heat integration in operation, and inability to support production planning and scheduling To achieve the effect of improving energy utilization efficiency, avoiding volatility and intermittency, and supporting power grid power peak regulation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

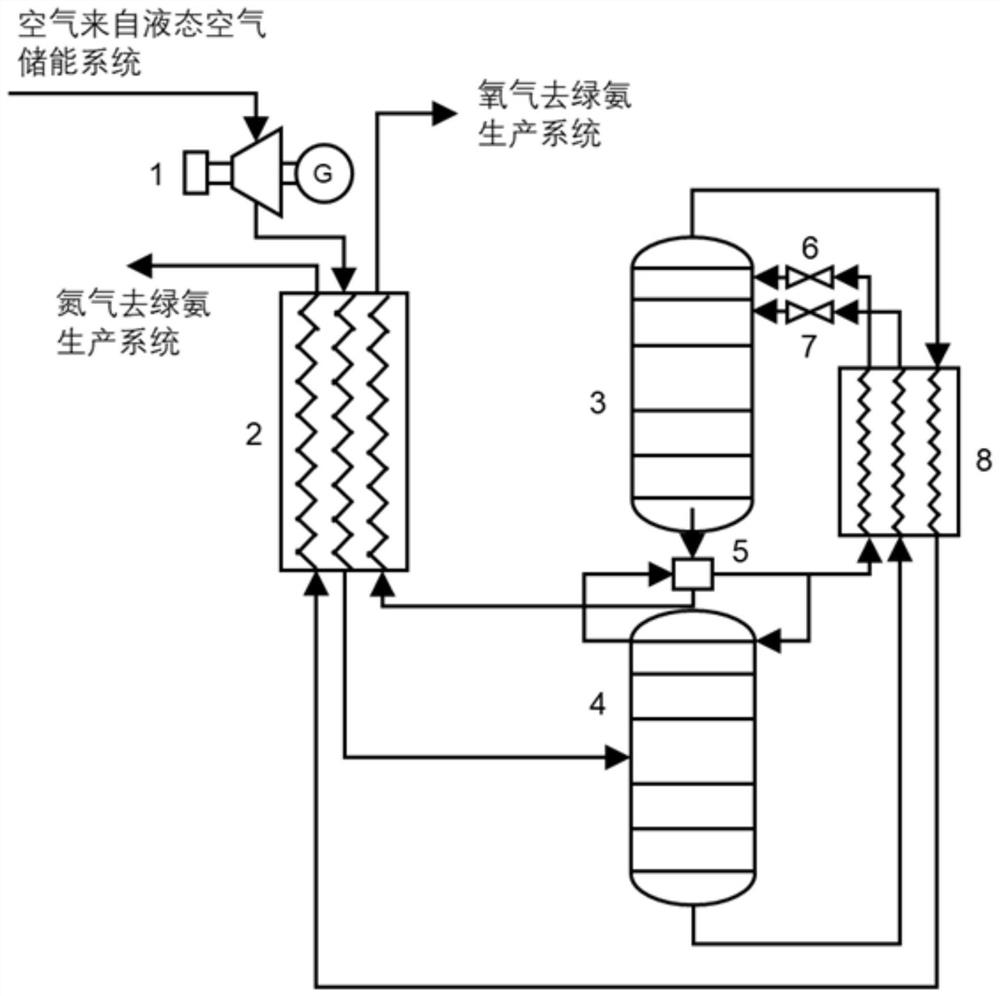

[0087] The accompanying drawings are for illustrative purposes only, and should not be construed as limiting the present invention; in order to better illustrate the present embodiment, some parts of the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art Some well-known structures in the drawings and their descriptions may be omitted for the staff.

[0088] In addition, the terms "first", "second", etc. are only used for descriptive purposes and should not be construed to indicate or imply relative importance or to imply indicate the number of the indicated technical features. Thus, a feature defined as "first", "second", etc., may expressly or implicitly include at least one of that feature.

[0089] It should also be understood that, in this application, the term "and / or" is only an association relationship for describing associated objects, indicating that there may be three kinds of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap