Energy-saving house using energy-saving plastic and glass curtain wall

A technology for glass curtain wall and energy-saving houses, which is applied to solar collectors using working fluids, solar thermal energy, working fluids of solar collectors, etc. Unable to achieve energy-saving effect and other problems, to achieve the effect of improving aesthetics, good absorption, and isolating the entry of external temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

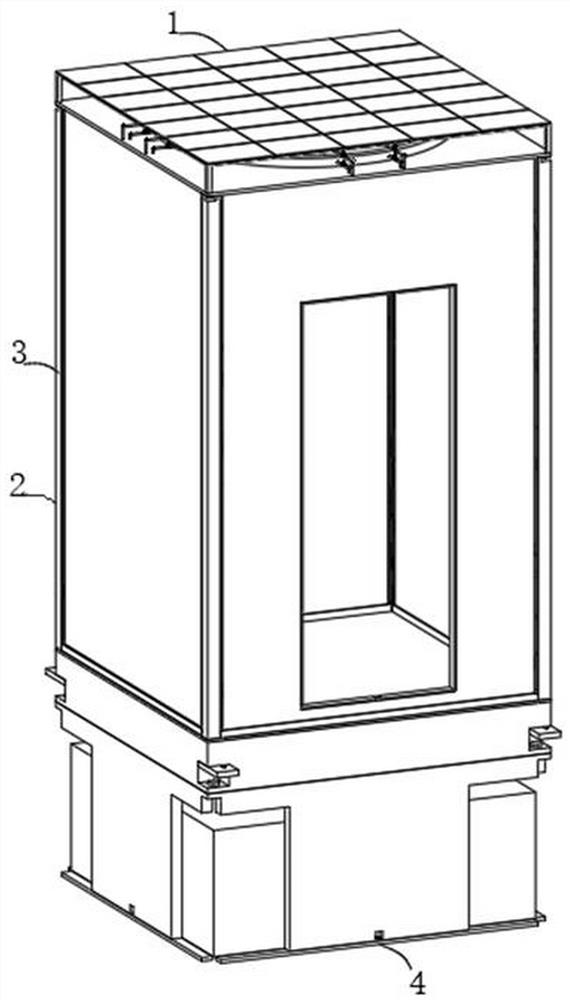

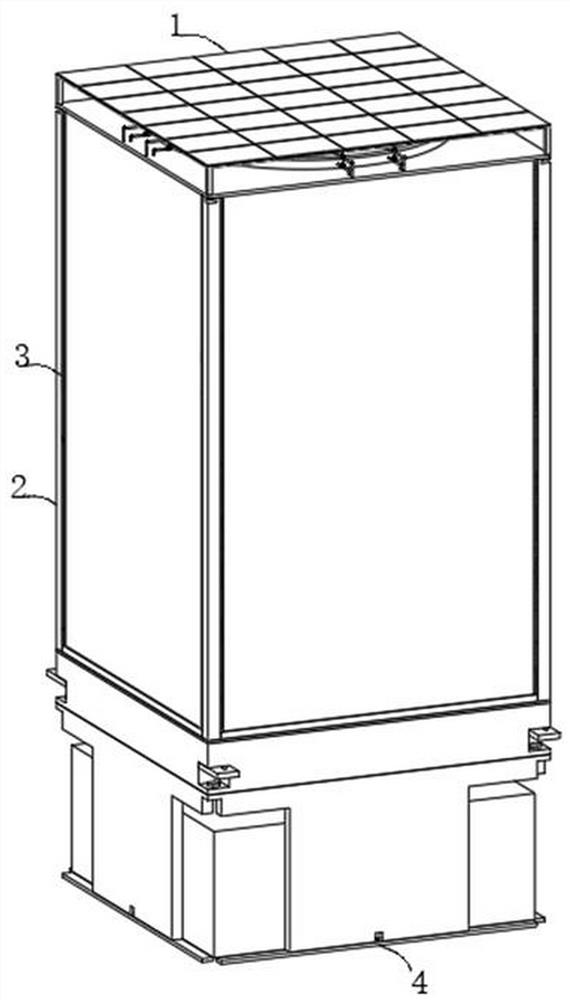

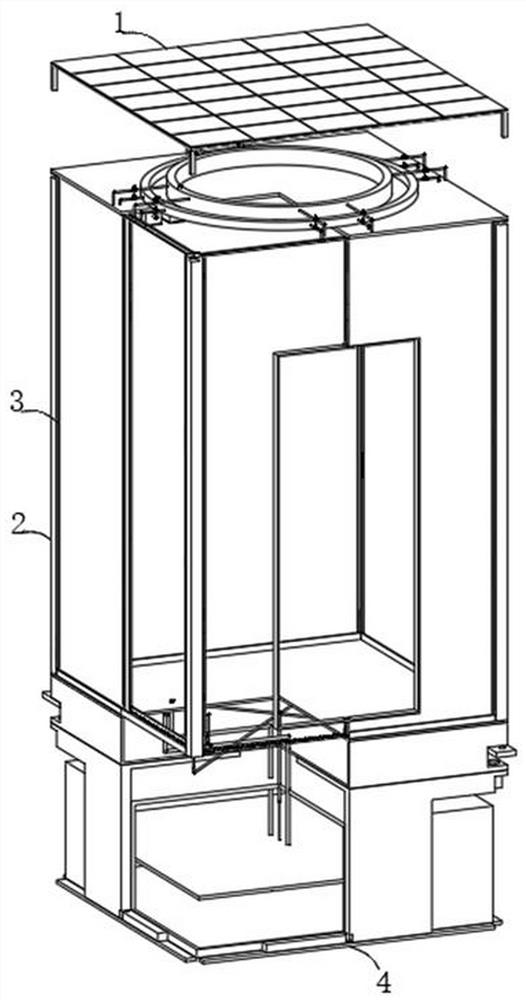

[0037] refer to Figure 1-Figure 14: An energy-saving house using energy-saving plastic and glass curtain walls, comprising: a first functional mechanism 1, a supporting mechanism 2, a protective mechanism 3 and a second functional mechanism 4, the second functional mechanism 4 includes a fixed seat 401, the establishment of the fixed seat 401 Provide a solid foundation for equipment construction, and also provide an installation basis for other functional components of the equipment. The bottom of the fixed seat 401 is fixedly connected with a plurality of limit plates 402 at equal distances. The establishment of the limit plates 402 is convenient for the installation and setting of other functional components of the equipment. A liquid storage frame 403 is arranged between the tops of the plurality of limit plates 402. The establishment of the liquid storage frame 403 can temporarily store solutions of different colors. A partition 404 is fixedly connected between the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com