Tempering method of large-size ultra-thin glass

An ultra-thin glass, large-scale technology, used in glass tempering, glass cutting devices, glass manufacturing equipment, etc., can solve the problem of product bending deformation, lack of good chemical tempering technology, prone to fragments, creases and surface pits and other problems, to achieve the effect of great feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0045] Based on the content recorded in the background art, when the ultra-thin glass with a size of 500*400 or more and a thickness of less than 50um is directly tempered by the traditional process, the fragmentation rate is almost 100%, and the size of the ultra-thin glass is relatively large. , there will also be adverse risks such as creases when tempering.

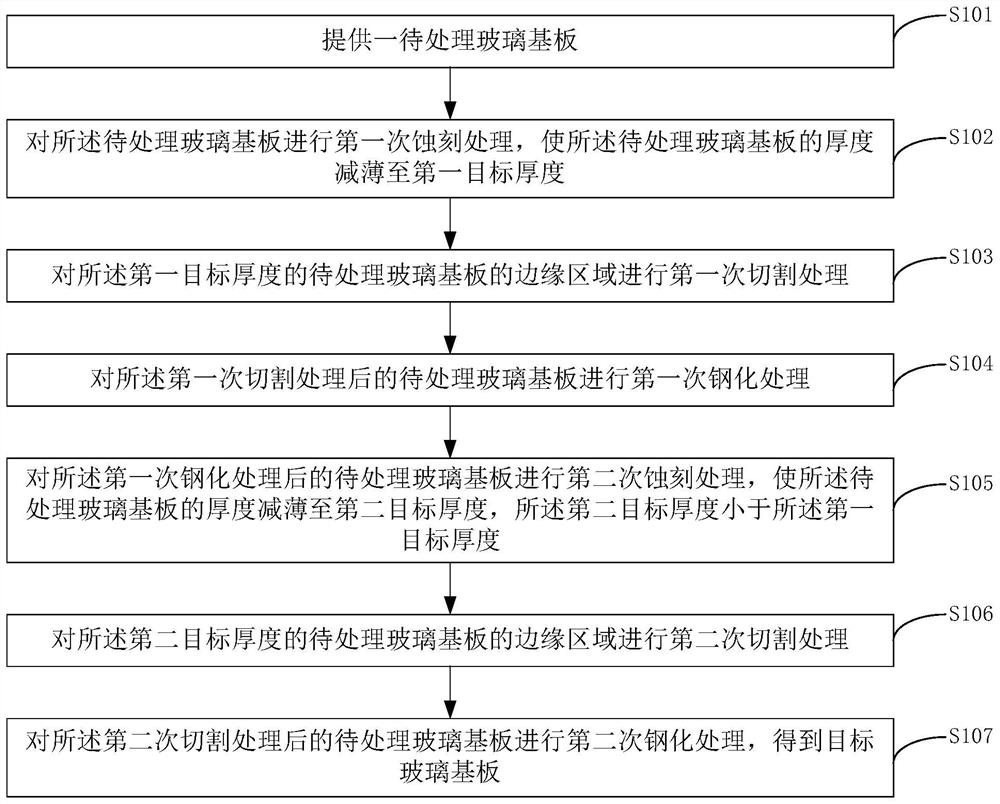

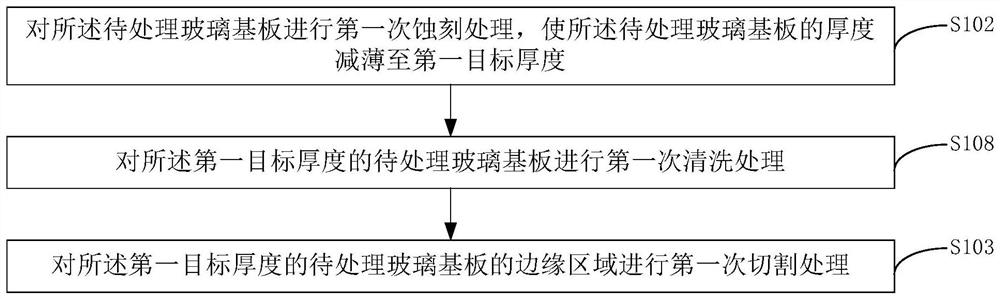

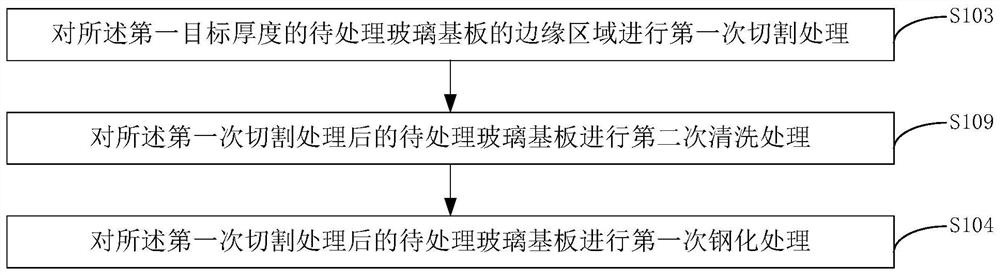

[0046] Based on this, the present invention provides a large-scale ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com