Method for simultaneously removing multiple impurities in hydrogen peroxide aqueous solution

A technology of hydrogen peroxide and aqueous solution, which is applied in the field of adsorption, can solve the problems that have not yet reached the G5 standard, and achieve the effects of efficient impurity removal, simple process, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for simultaneously removing multiple impurities in an aqueous hydrogen peroxide solution. The method goes through the following steps in sequence:

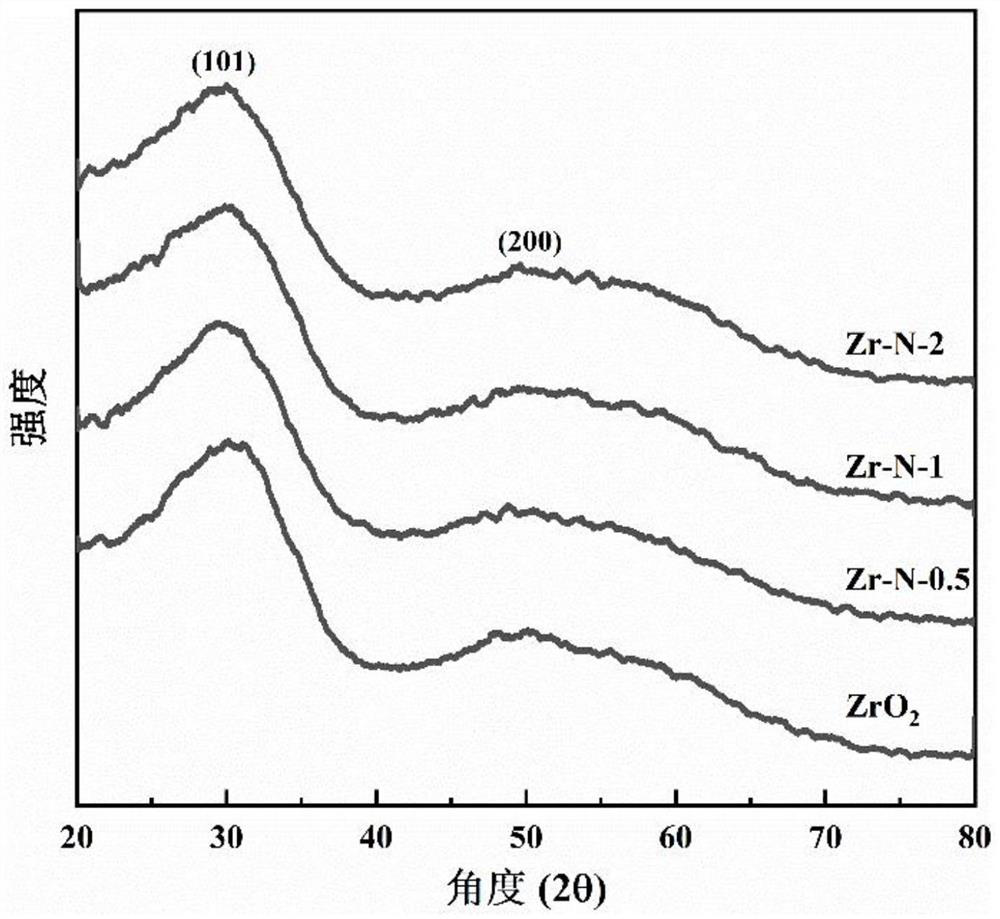

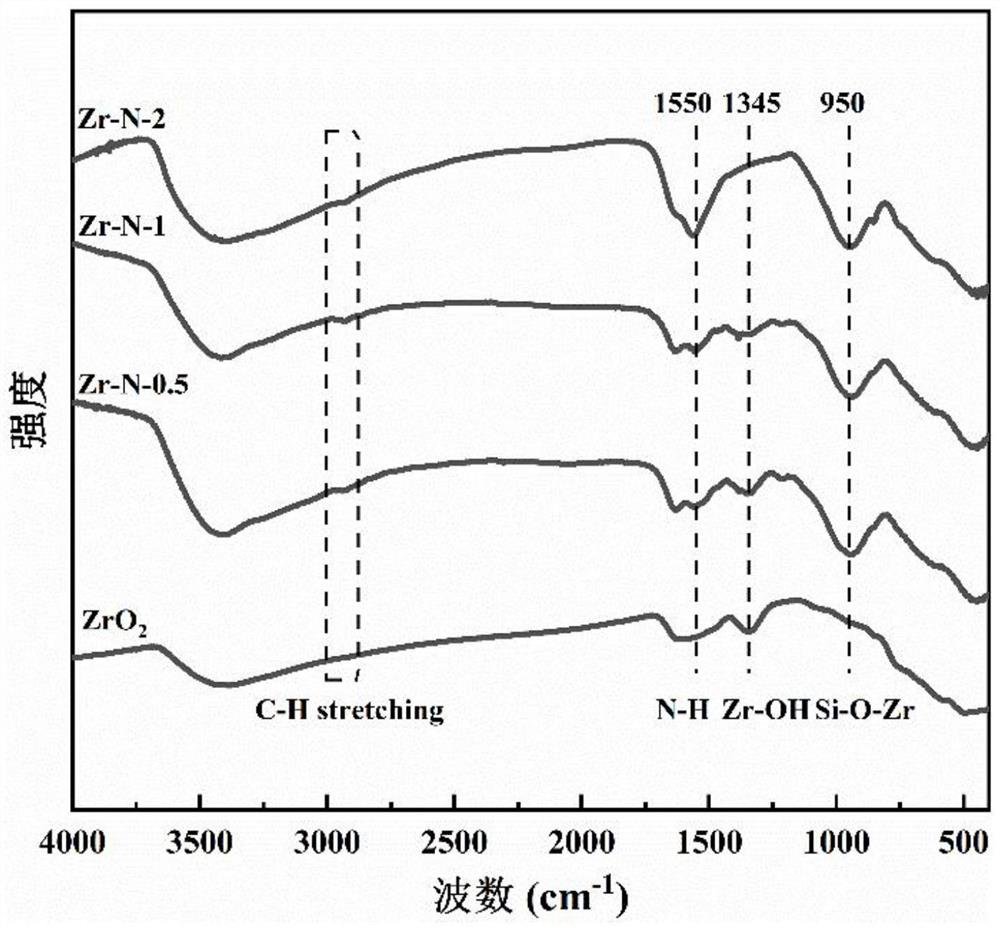

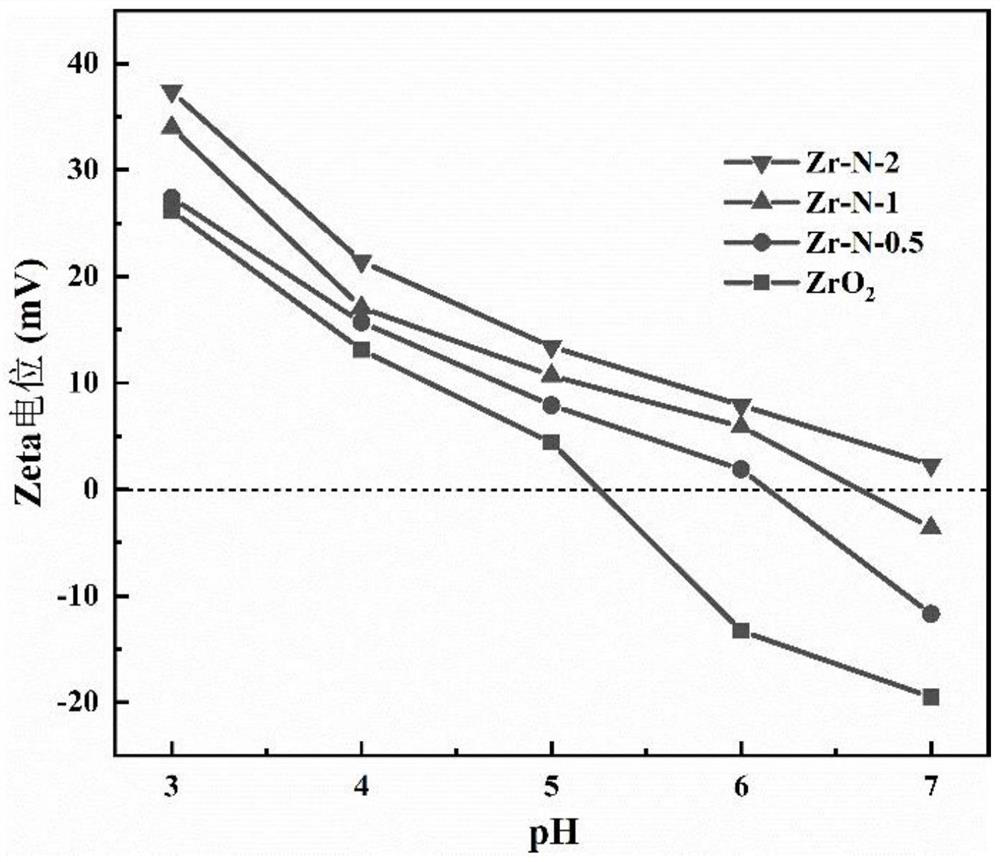

[0046] (1) The amino-functional zirconia was prepared by grafting silane coupling agent (APTES) on zirconia by copolycondensation method, wherein the molar ratio of silane coupling agent to zirconia was 0.5; The structure is amorphous, such as figure 1 shown.

[0047] The specific operation of the copolycondensation method is as follows: 24 mmol of KOH and 0.6 mmol of CTAB surfactant are dissolved in 50 mL of deionized water, and stirred at 80° C. for 0.5 hour. Then, 4 mmol of zirconium n-butoxide and 8 mmol of APTES were sequentially added to the solution, and it was observed that a precipitate formed rapidly, and the reaction was carried out at 80 °C for 3 hours. The resulting solid was filtered while hot, washed sequentially with deionized water and ethanol, and dried at 110°C. Finally, the obtained solid wa...

Embodiment 2

[0054] A method for simultaneously removing multiple impurities in an aqueous hydrogen peroxide solution. The method goes through the following steps in sequence:

[0055] (1) Amino-functionalized zirconia is prepared by grafting APTES on zirconia by a copolycondensation method, wherein the molar ratio of the silane coupling agent to the zirconia is 1; the specific preparation method is the same as that in Example 1.

[0056] (2) the concentration of the industrial-grade hydrogen peroxide is 29.38wt%;

[0057] (3) 20 mL of the aqueous hydrogen peroxide solution in step (2) was taken and adsorbed with 20 mg of the amino-functionalized zirconia in step (1) in a round-bottomed flask for 1 hour, and the adsorption experiment was carried out under a water bath condition of 30°C.

[0058] The changes of the impurity content in the hydrogen peroxide aqueous solution before and after adsorption are shown in Table 3. The concentration of the hydrogen peroxide aqueous solution after a...

Embodiment 3

[0062] A method for simultaneously removing multiple impurities in an aqueous hydrogen peroxide solution. The method goes through the following steps in sequence:

[0063] (1) Amino-functionalized zirconia is prepared by grafting APTES on zirconia by a copolycondensation method, wherein the molar ratio of the silane coupling agent to the zirconia is 2; the specific preparation method is the same as that in Example 1.

[0064] (2) the concentration of the industrial-grade hydrogen peroxide is 29.38wt%;

[0065] (3) Take 20 mL of the aqueous hydrogen peroxide solution in step (2), and adsorb 20 mg of the amino-functionalized zirconia in step (1) in a round-bottomed flask for 1 hour. The adsorption experiment was carried out under a water bath condition of 30°C.

[0066] The change of impurity content in the hydrogen peroxide aqueous solution before and after adsorption is shown in Table 4. The concentration of the hydrogen peroxide aqueous solution after adsorption was 28.69 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com